Patents

Literature

30 results about "Process adaptation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

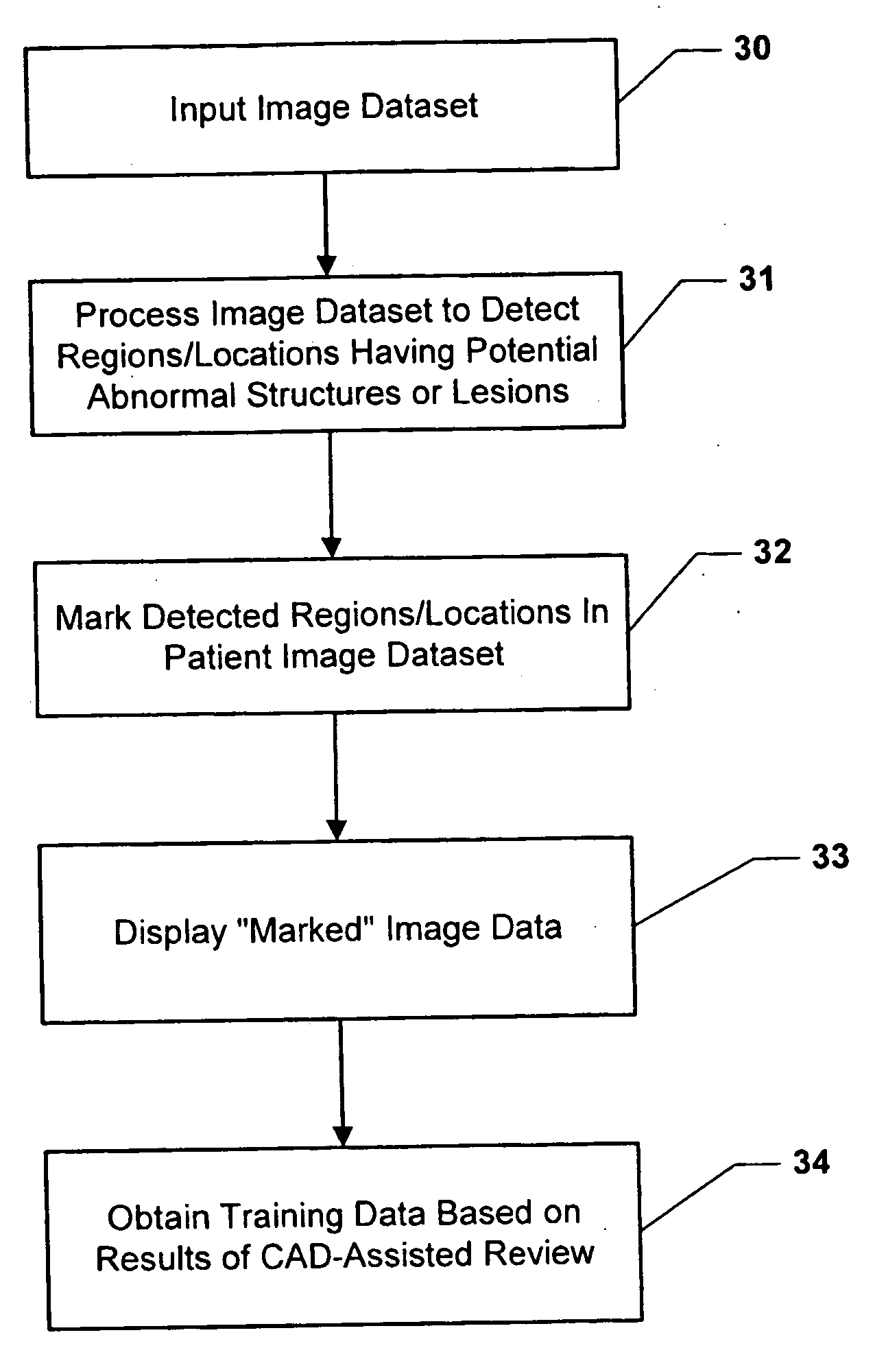

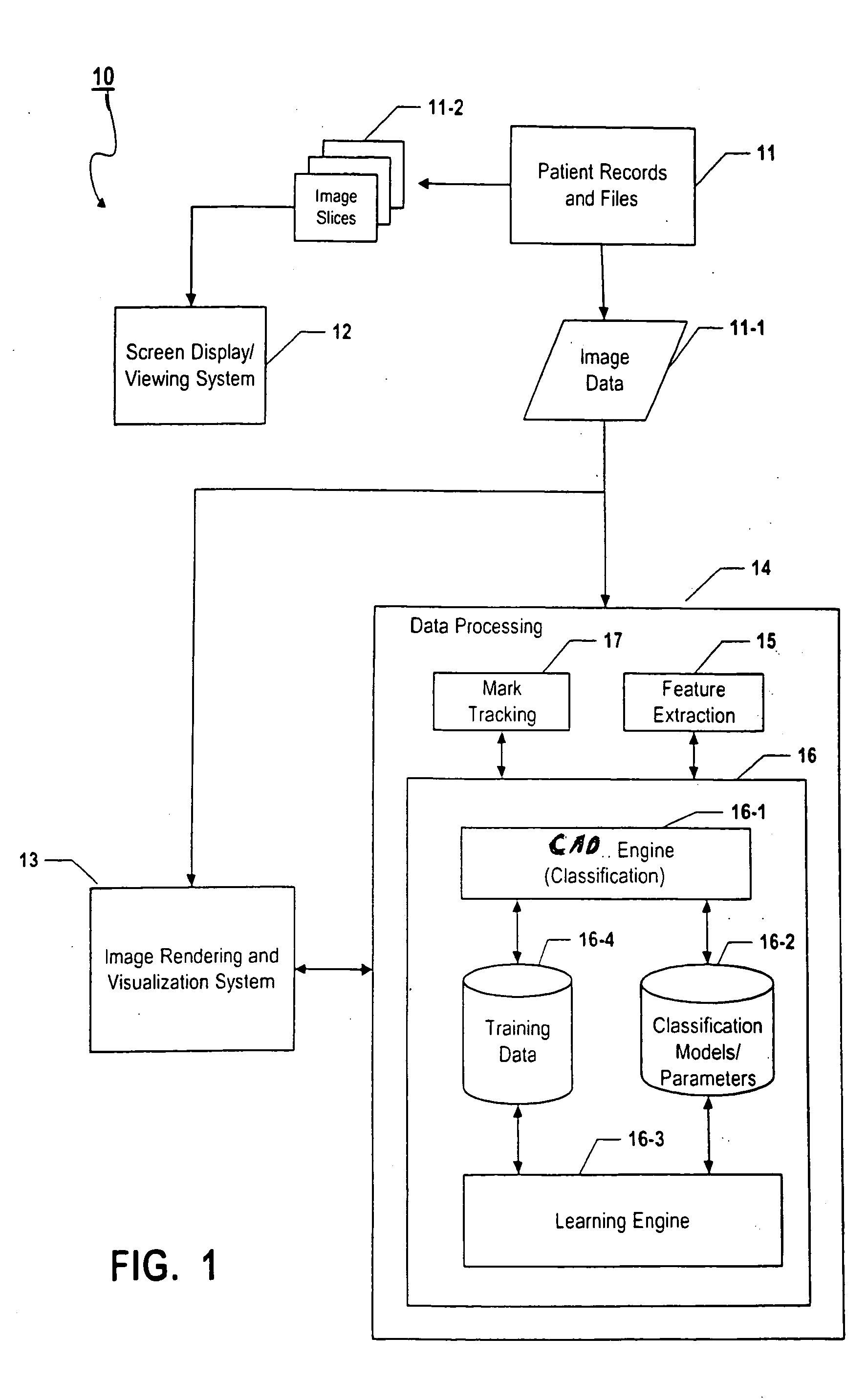

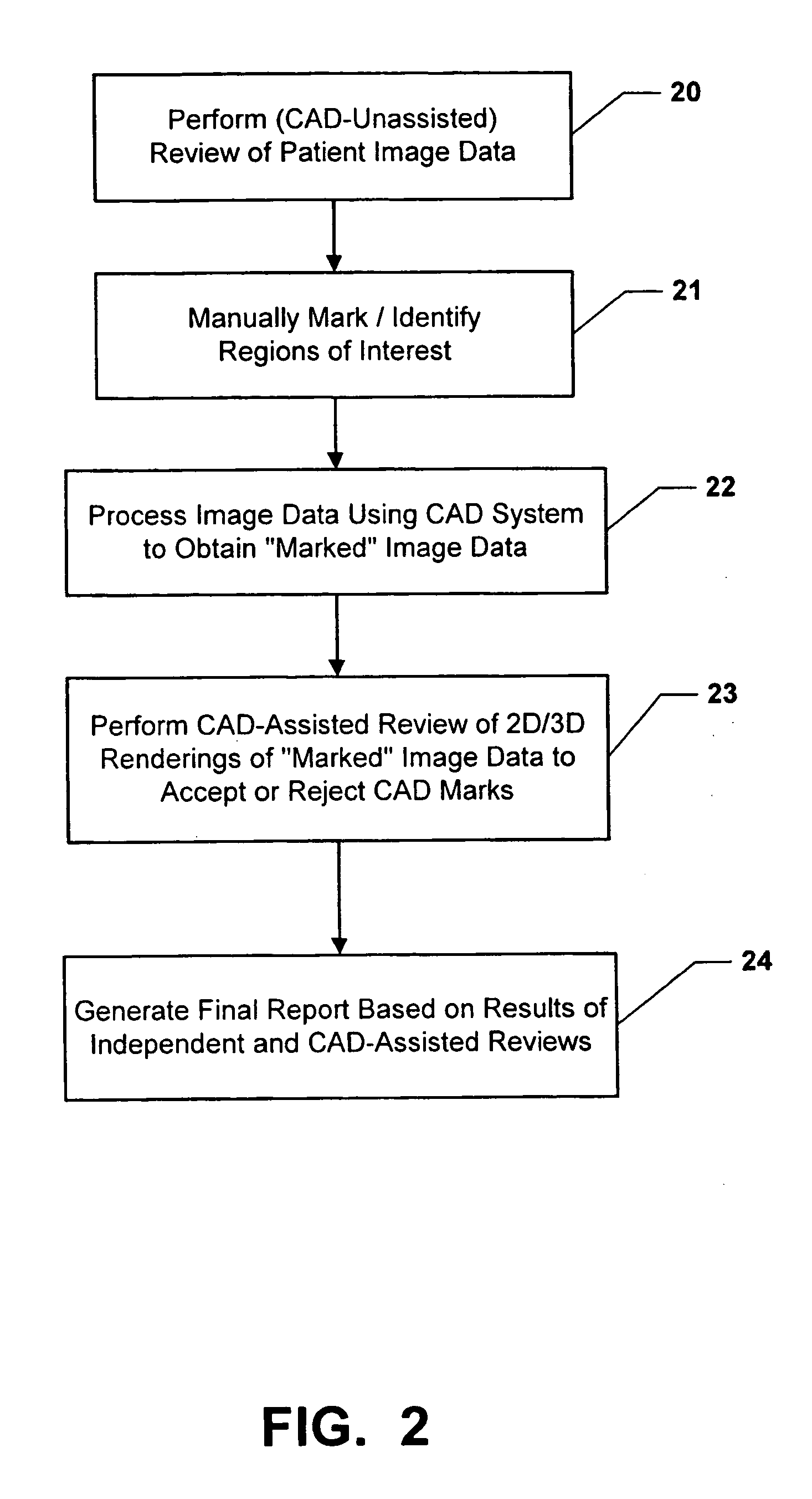

CAD (computer-aided decision) support for medical imaging using machine learning to adapt CAD process with knowledge collected during routine use of CAD system

ActiveUS20050010445A1Ultrasonic/sonic/infrasonic diagnosticsImage enhancementSupporting systemEngineering

CAD (computer-aided decision) support systems, methods and tools for medical imaging are provided, which use machine learning classification for automated detection and marking of regions of interest in medical images. Machine learning methods are used for adapting / optimizing a CAD process by seamlessly incorporating physician knowledge into the CAD process using training data that is obtained during routine use of the CAD system.

Owner:SIEMENS HEALTHCARE GMBH

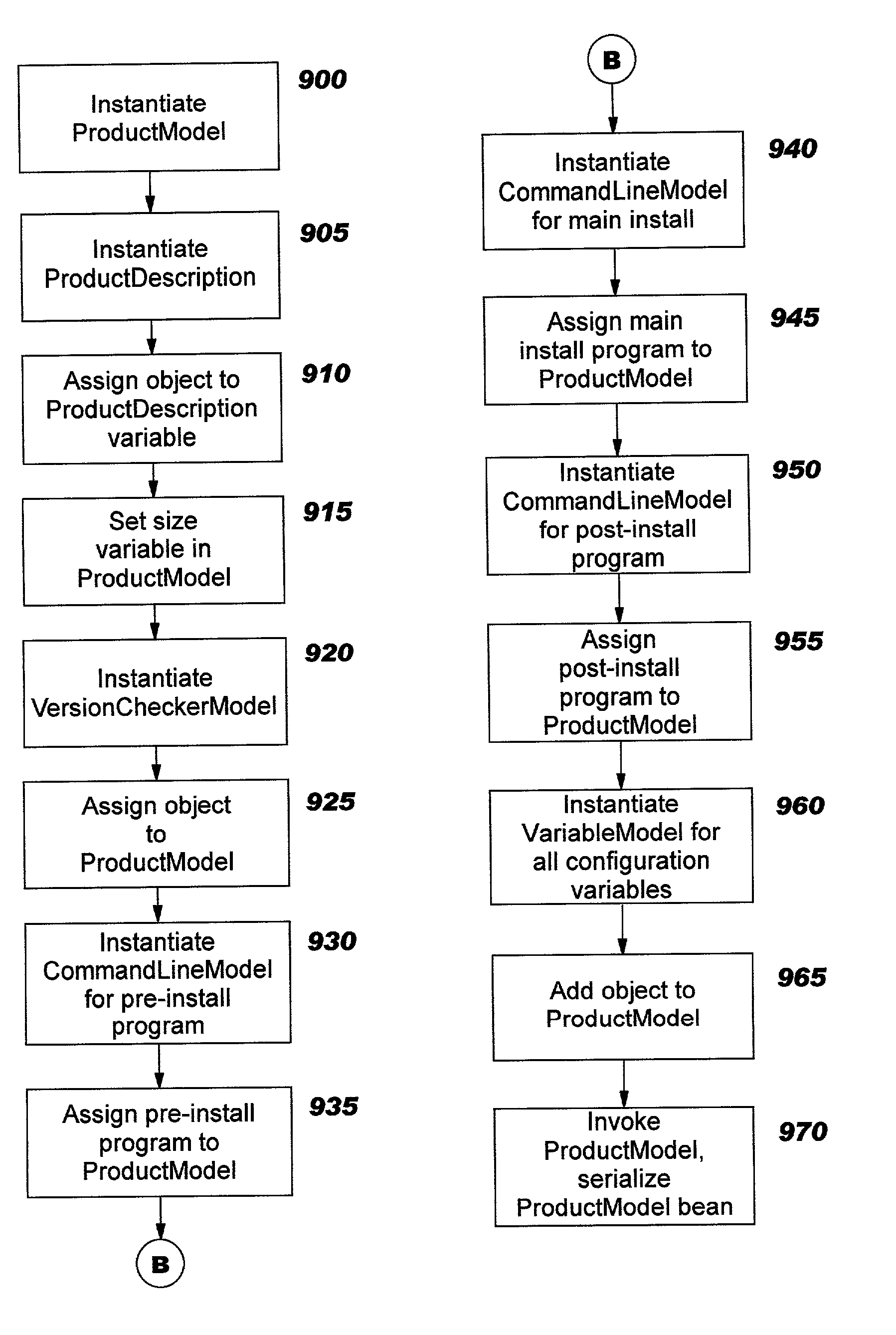

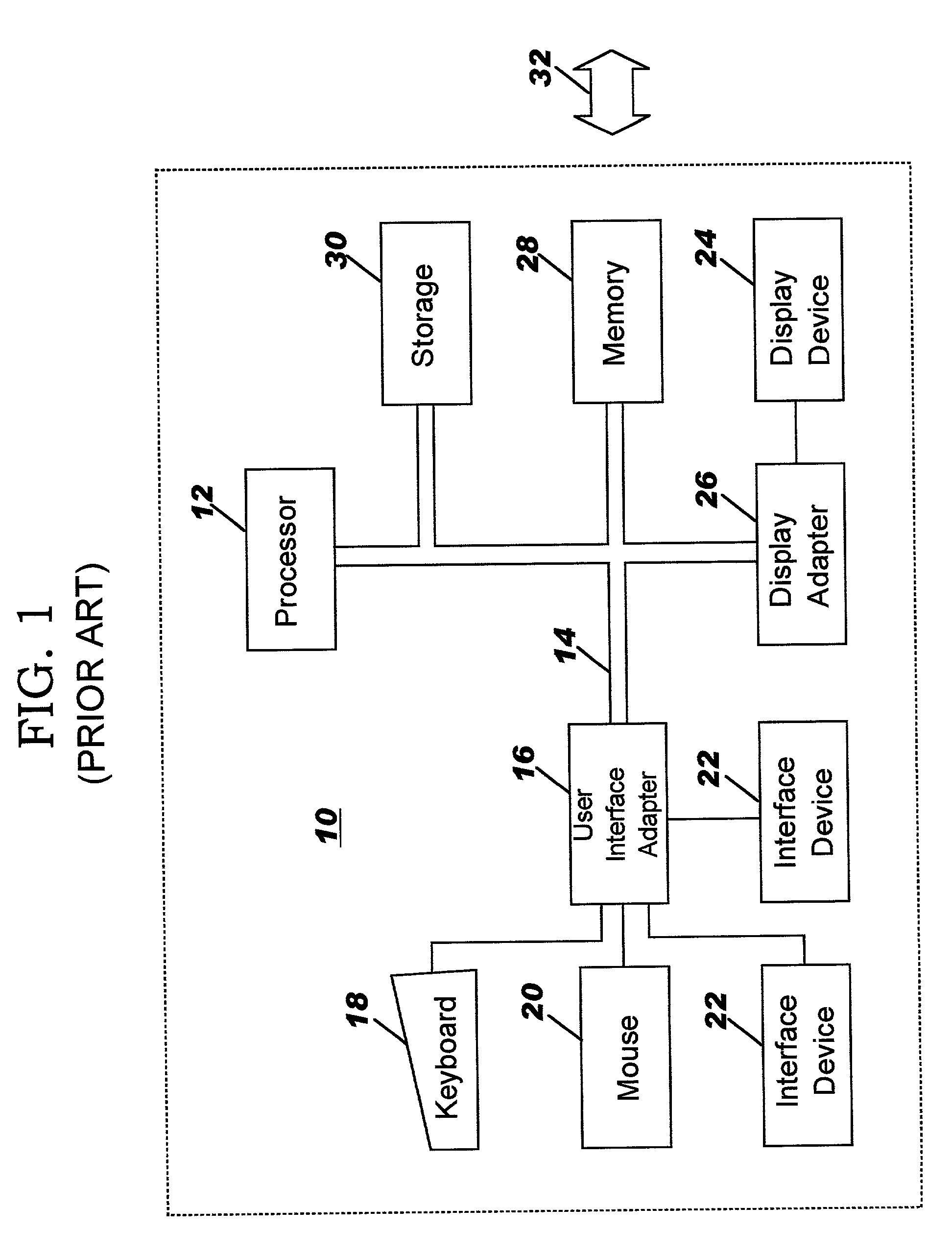

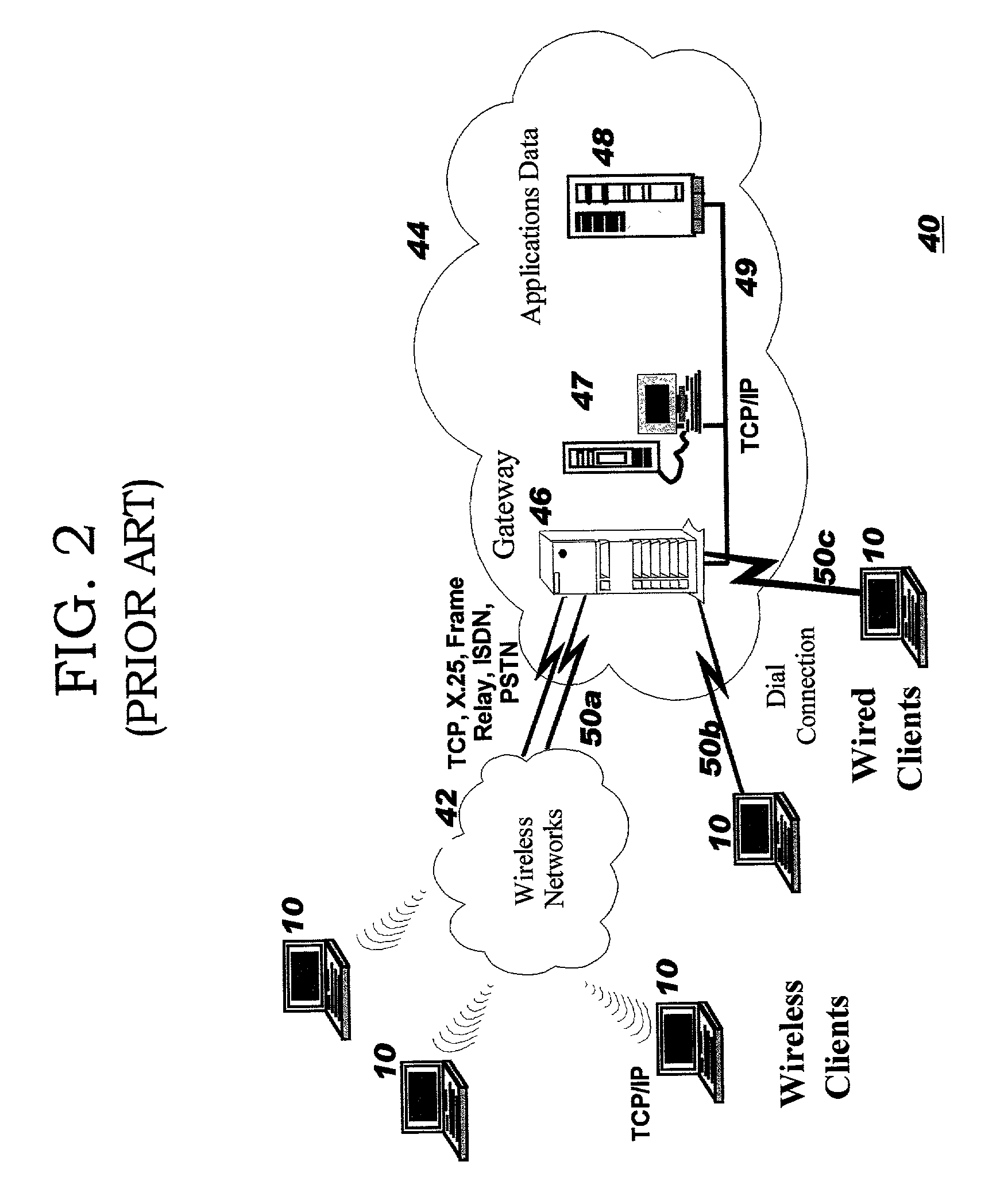

Extending installation suites to include topology of suite's run-time environment

InactiveUS20030037328A1Flexible and efficientProgram loading/initiatingMemory systemsSoftware engineeringProcess adaptation

Methods, systems, and computer program products for improving installation of software suites by including topological information pertaining to the run-time environment of products in the suite. A model and framework are described, where the objects of the data model include one or more preferred topologies. A template may be provided for each topology, with which an installer enters data values for customizing this topology. The approach disclosed herein enables more efficient and flexible software installation than is available in the prior art, by adapting the installation process for a particular topology of a destination run-time environment. Using the disclosed techniques, a solution builder is able for the first time to enforce or recommend the topology which is most efficient for this end solution. (For example, the solution builder may specify the types of machines which comprise a preferred run-time environment for the software products in the suite.)

Owner:IBM CORP

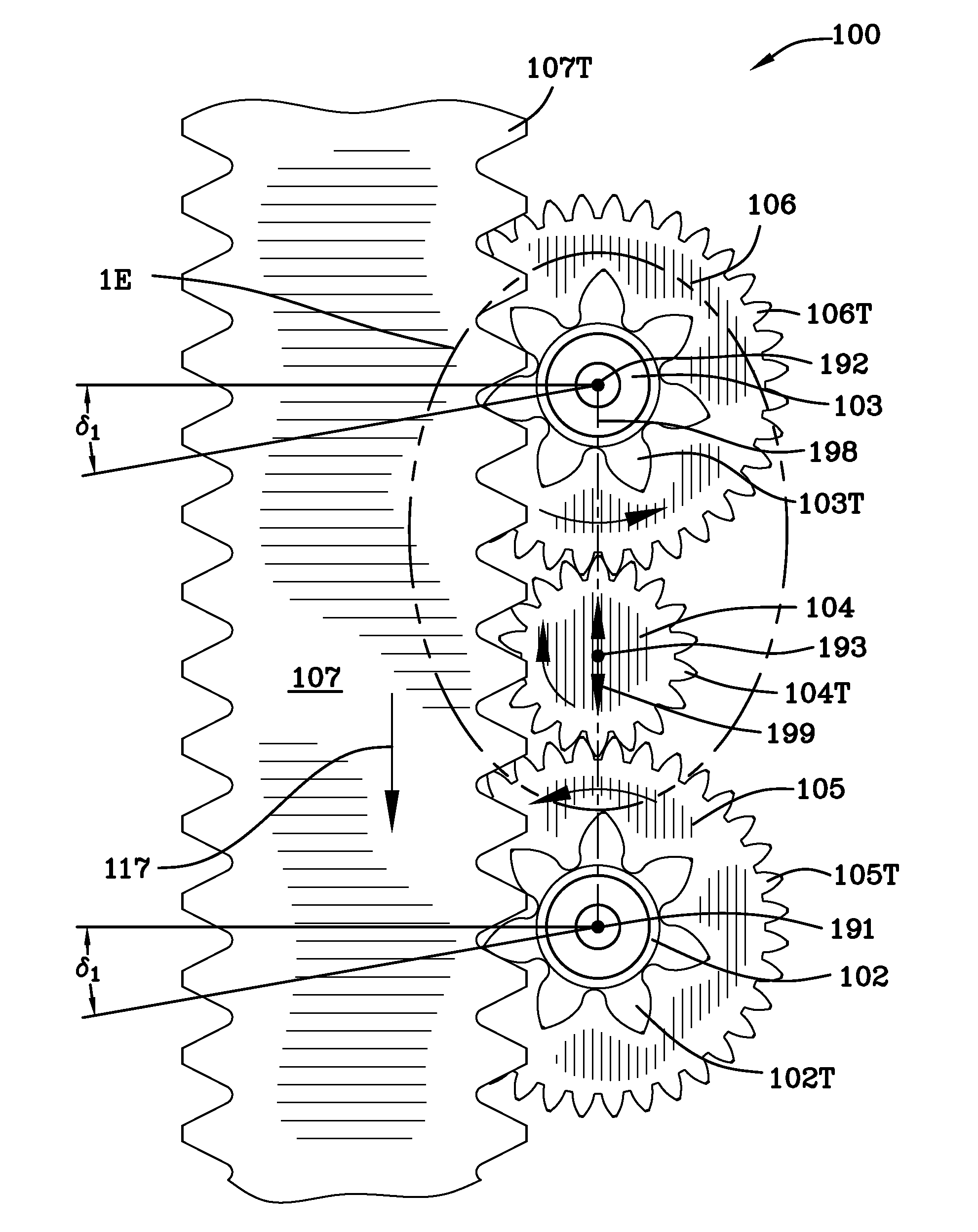

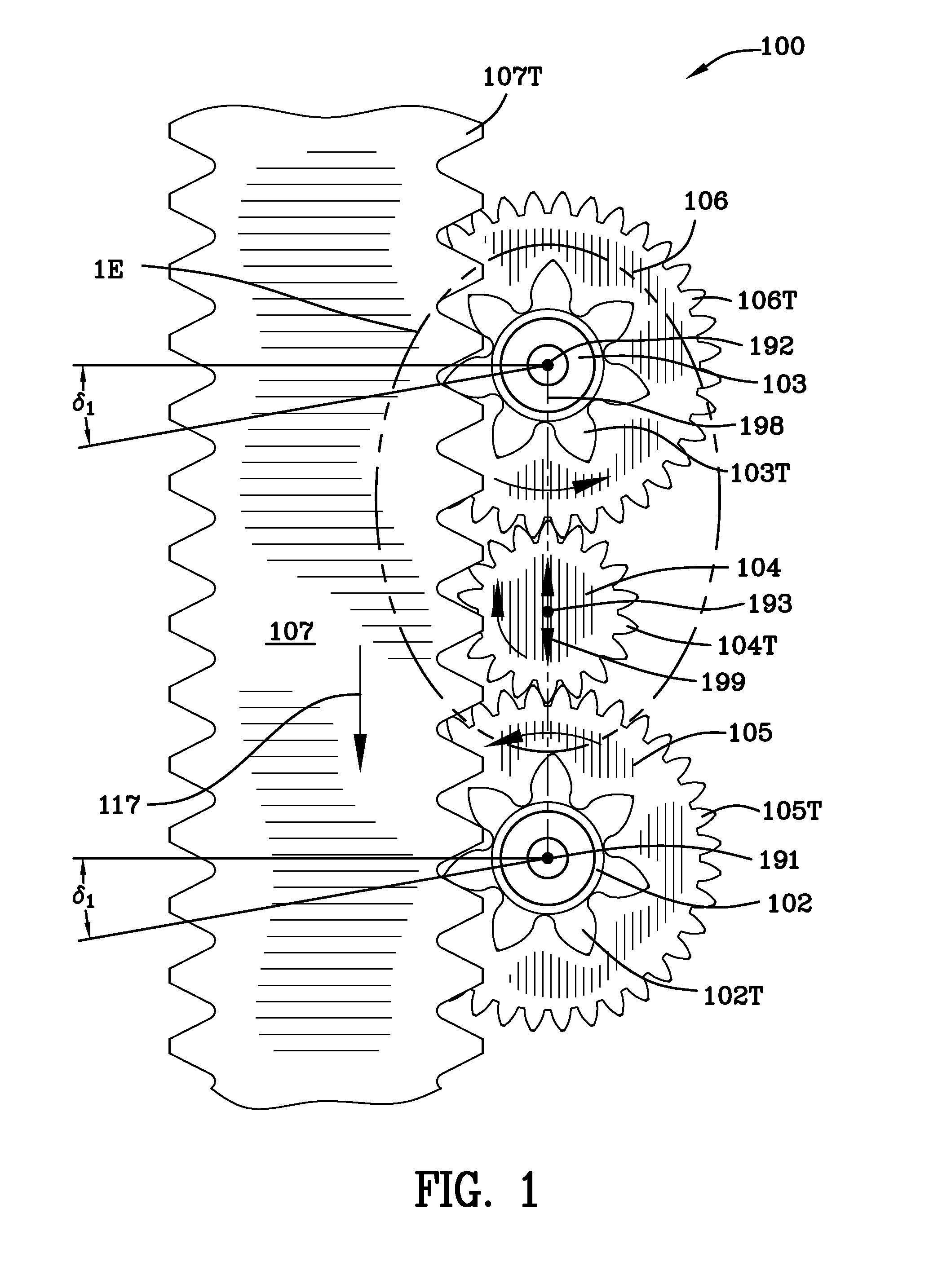

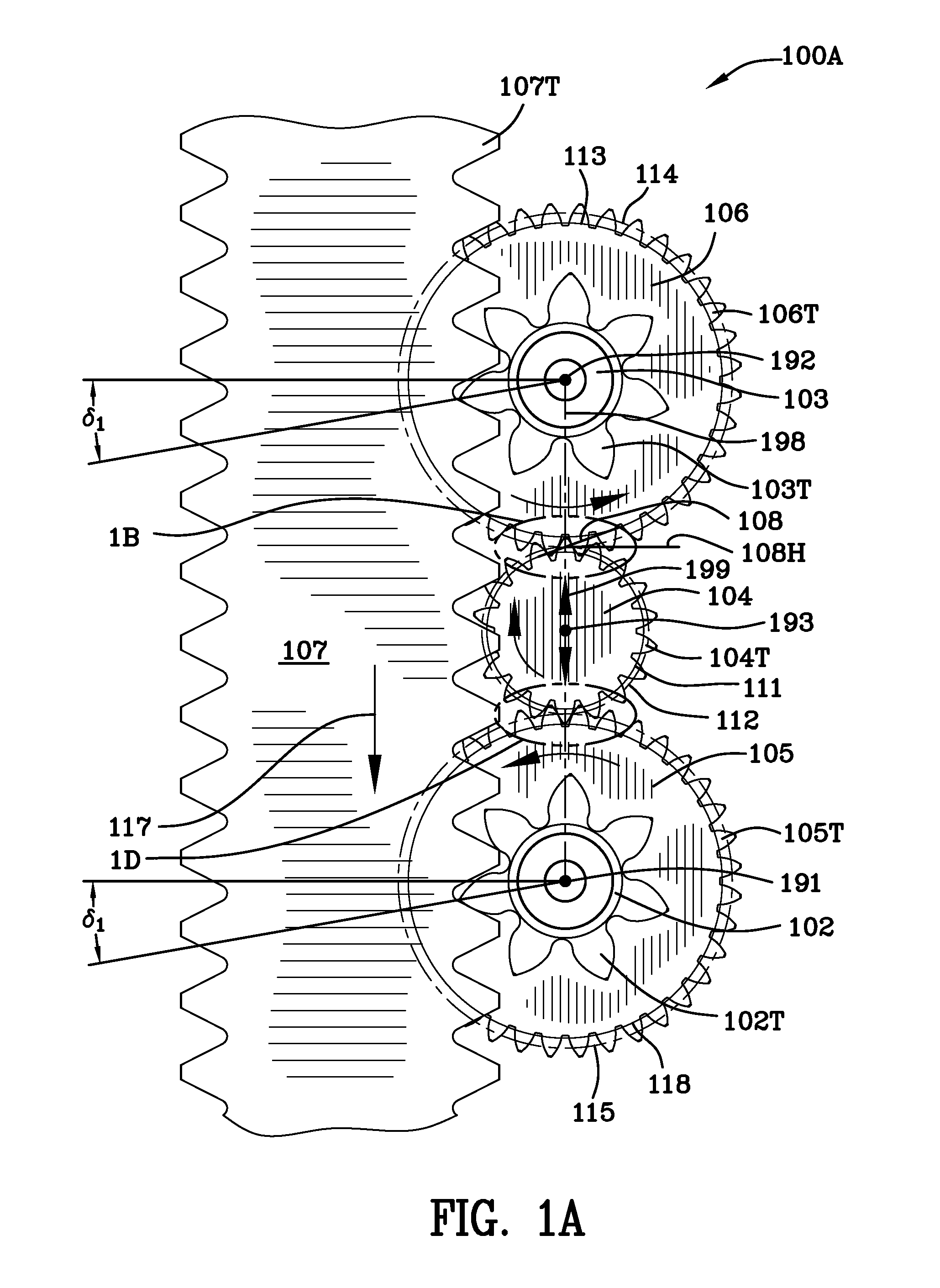

Torque Sharing Drive And Torque Sharing Process

ActiveUS20140208894A1Flexibly attachedEqual loadingToothed gearingsGearing detailsProcess adaptationControl theory

A torque sharing drive and process for sharing torque accommodates tooth inaccuracies on the rack and outer pinions. A driving pinion mates with first and second gears. The driving pinion is radially, bidirectionally, movable in response to gear separation forces only along the line between the centers of the driving pinion, the first gear and the second gear. First and second outer pinions are rotatable with the first and second gears, and as the driving pinion moves radially toward the first or second gear in response to gear separation forces, the first or second gear is angularly and rotationally advanced with respect to the other gear accommodating inaccuracies in the teeth of the rack and outer pinions. Alternatively, when gear separation forces are balanced, the driving pinion resides approximately equidistantly intermediate the first and second gear and the first and second outer pinions are approximately in phase.

Owner:GUSTOMSC RESOURCES BV

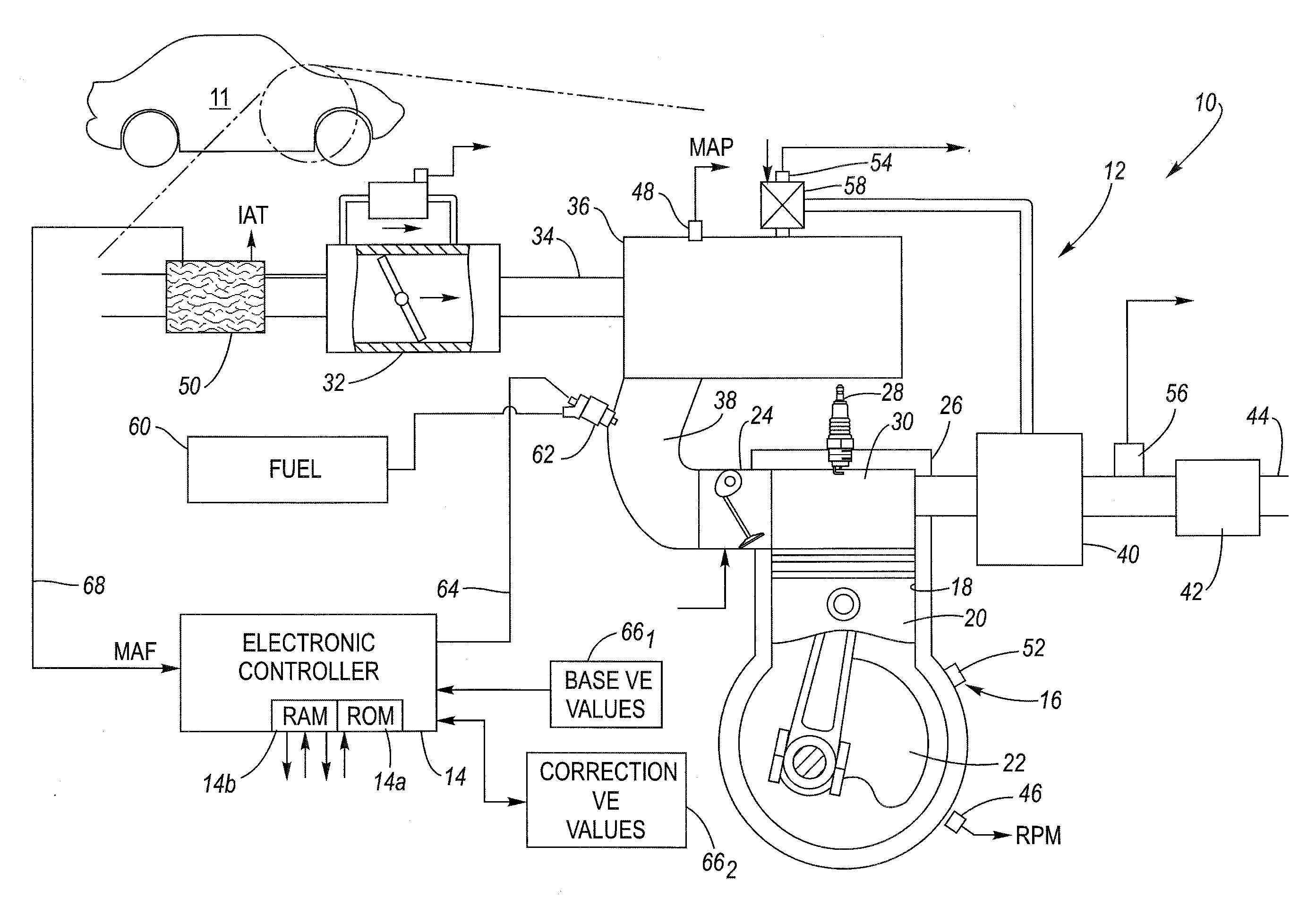

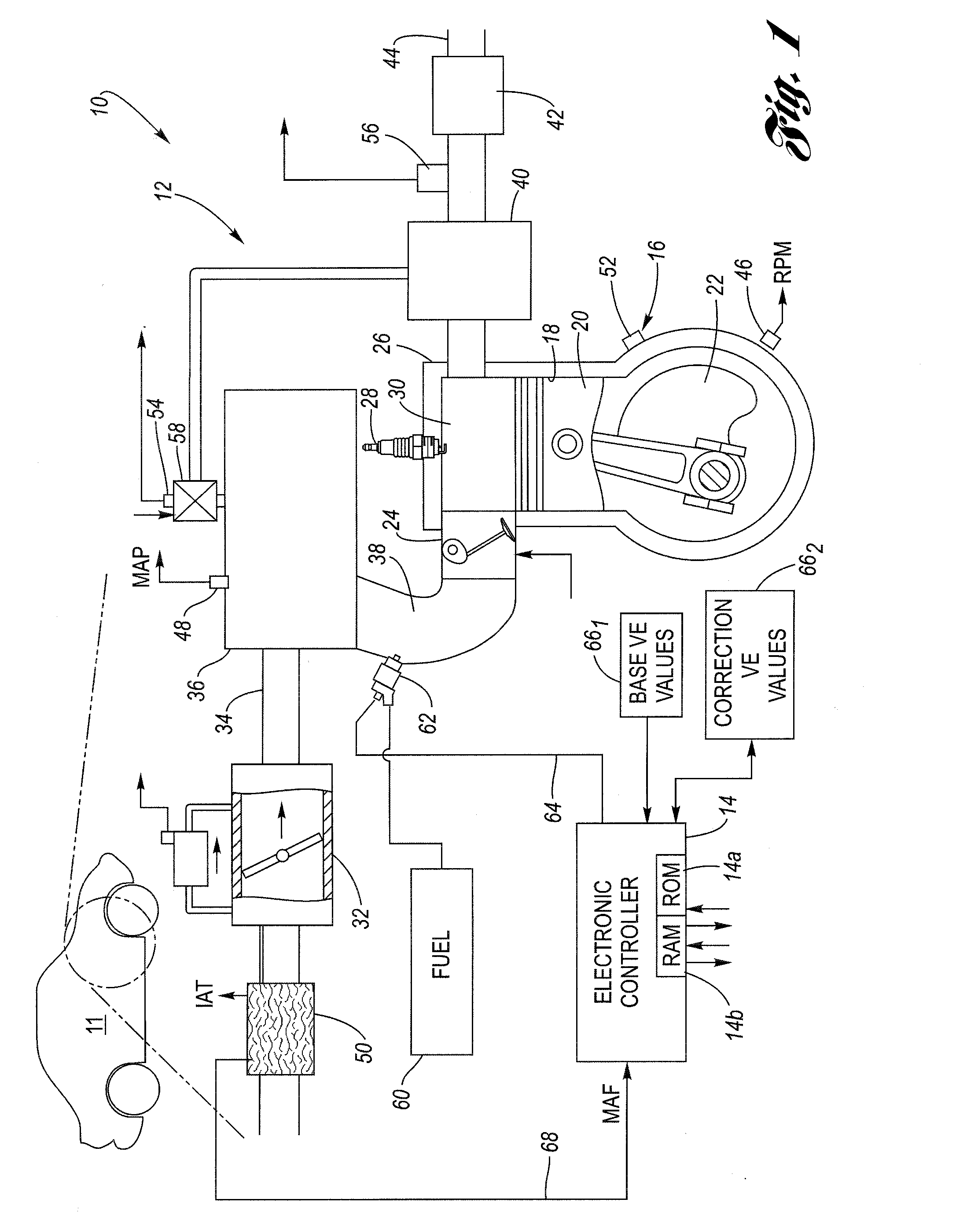

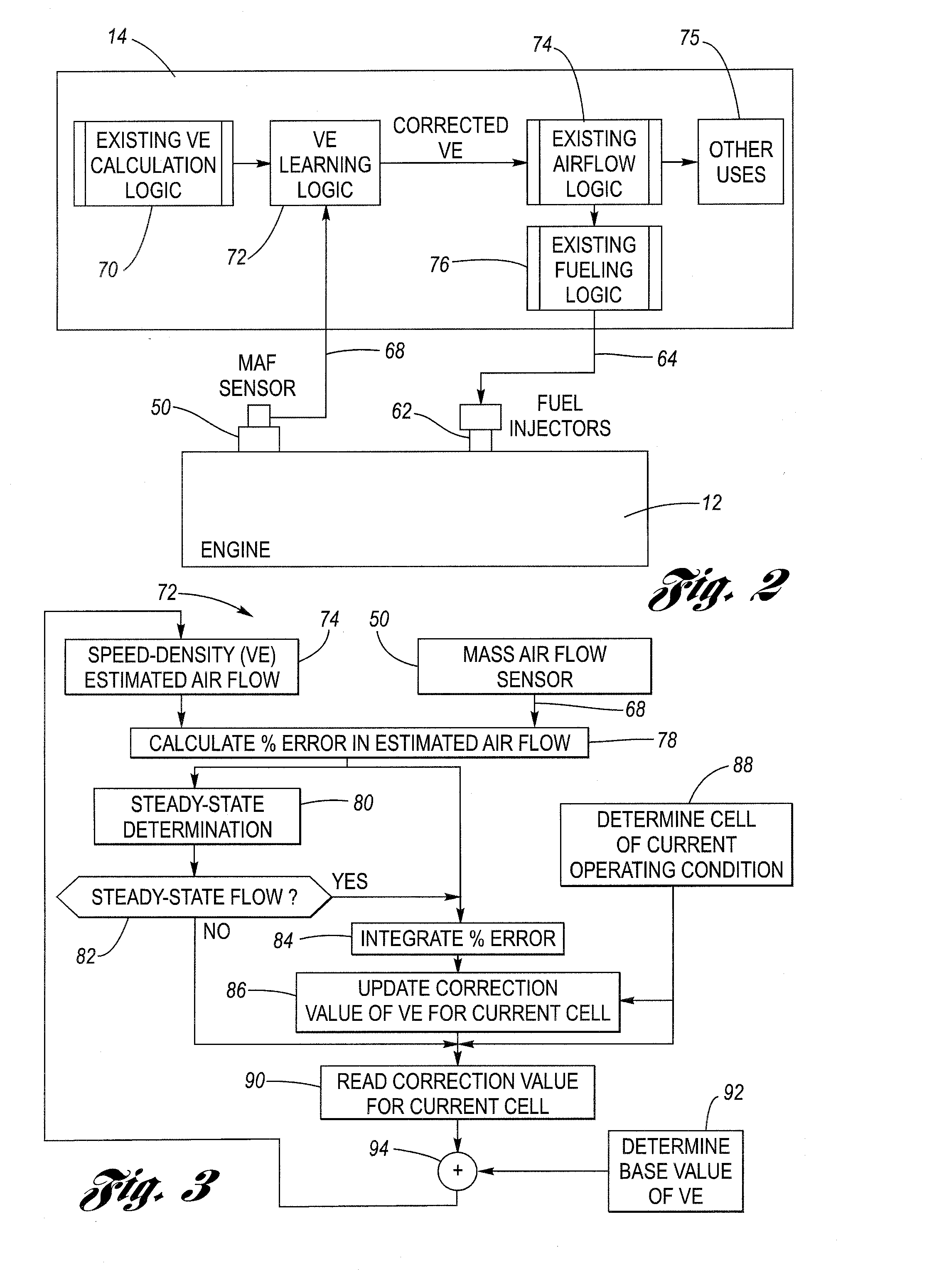

Method for on-line adaptation of engine volumetric efficiency using a mass air flow sensor

InactiveUS20090049897A1Simplifies initial calibration processImproves crank-to-run air flow calculationInternal-combustion engine testingElectrical controlStable stateProcess adaptation

An electronic engine controller is configured to execute a process of adapting a base value of the volumetric efficiency of an engine through the addition of a correction value of the volumetric efficiency. The process includes comparing an estimated mass air flow value calculated using a speed-density equation, with an actual mass air flow value measured by a mass air flow (MAF) sensor. A percentage error of the estimated mass air flow value as compared to the actual mass air flow value is calculated. When the percentage error indicates that the air flow is at steady state, then the process updates the VE correction value, by integrating the percentage error. The new correction value, thus computed, is then stored in a cell of an array corresponding to the current engine operating condition. The process is configured to add the correction value to the corresponding base value to produce an updated value of the VE, valid for that operating condition. The process accommodates changes in the volumetric efficiency of the engine due to part aging and deposit build-up over time, among other things. The updated VE value may then be used for mass air flow estimation and accordingly for fueling control as well.

Owner:DELPHI TECH INC

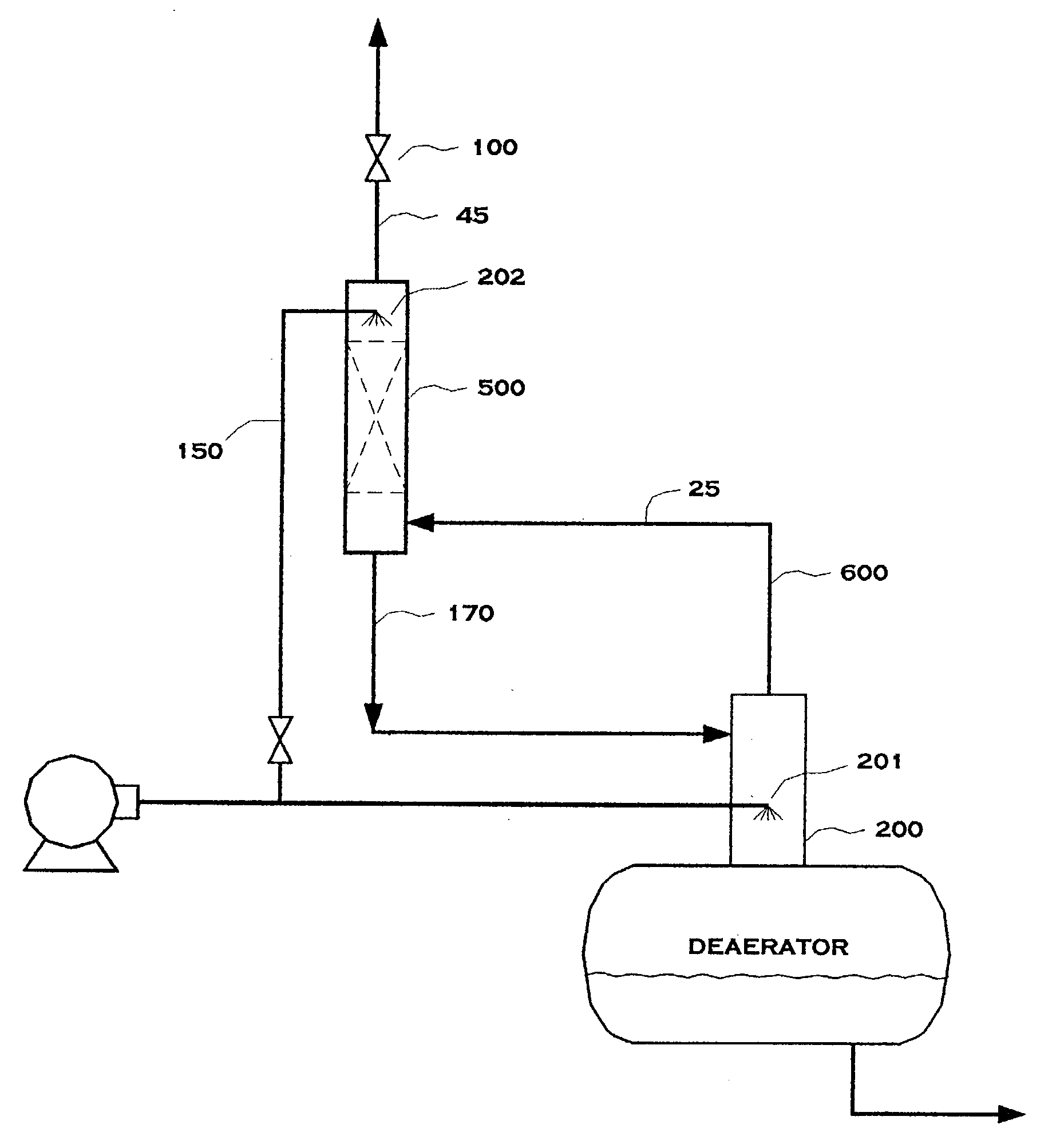

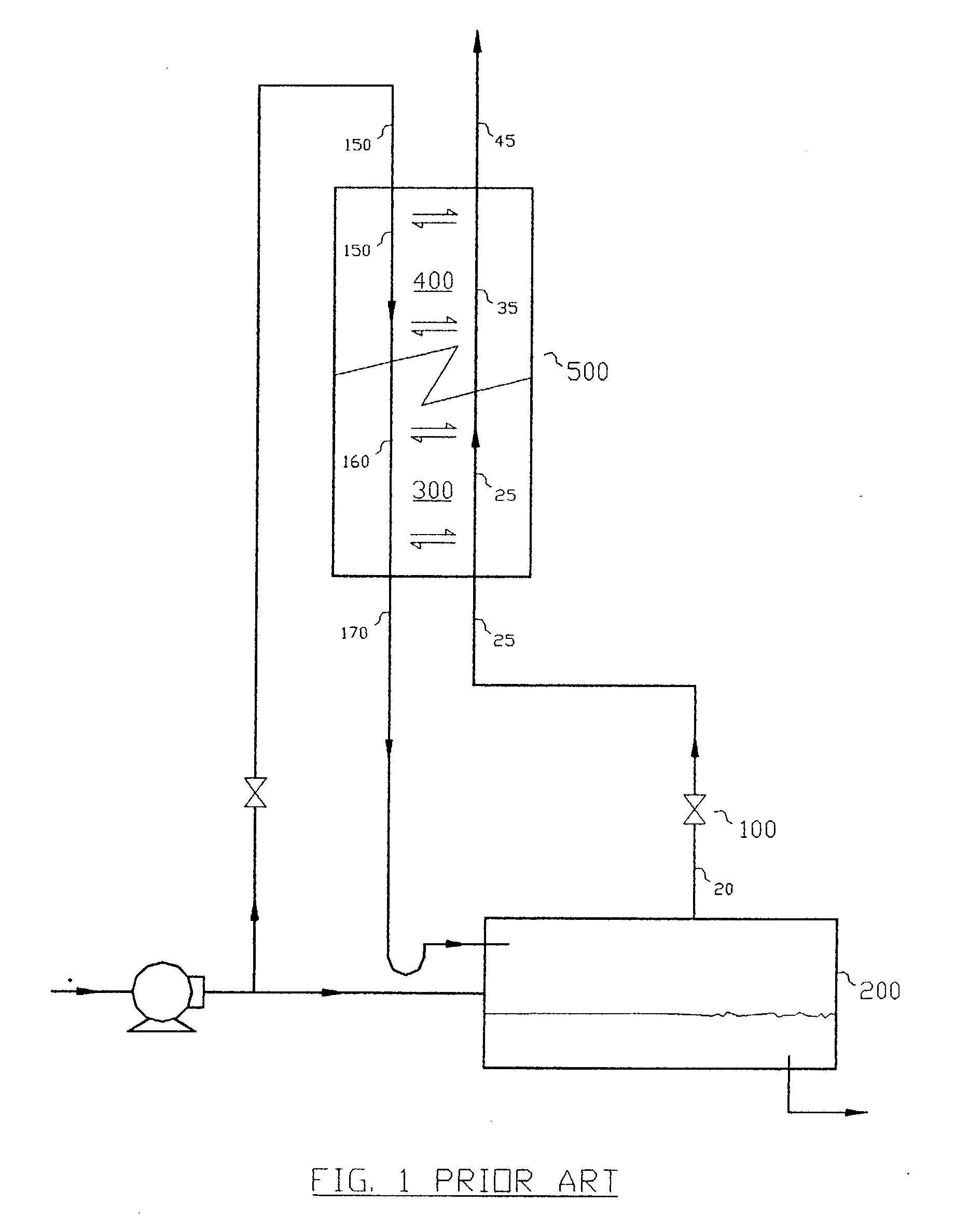

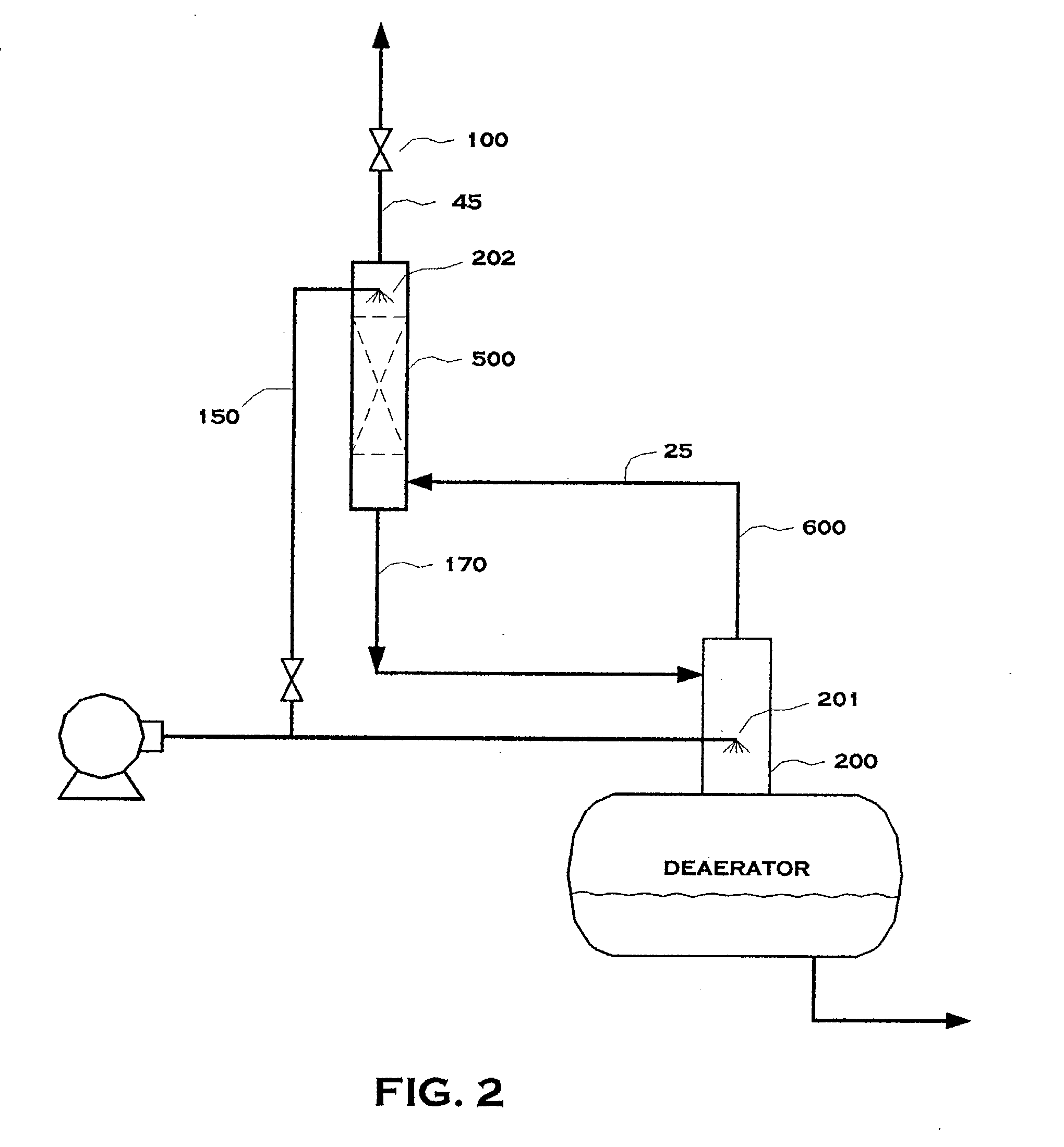

Staged heat and mass transfer applications

InactiveUS20040168900A1Easy to operateImprove reliabilityDistillation regulation/controlDistillation in boilers/stillsParticulatesSteam condensation

This invention exploits the concept of Staged Heat and Mass Transfer (SHMT) to enhance operability, control robustness and intrinsic safety in preventing corrosion while recovering material, and energy if desirable, in process waste streams. Two applications illustrating the improvements based on the SHMT concept are given. One application illustrates novel design features to recover vent from a steam boiler deaeration system, positively eliminating the risk of oxygen and carbon dioxide accumulation in deaerator. The other application illustrates process adaptations of the same SHMT concept to recover steam, steam condensate, and fugitive emissions involving particulate materials if desirable, from any process vents from vessels that are opened to the atmosphere. Again, without the risk of corrosion by atmospheric oxygen.

Owner:TUNG PETER

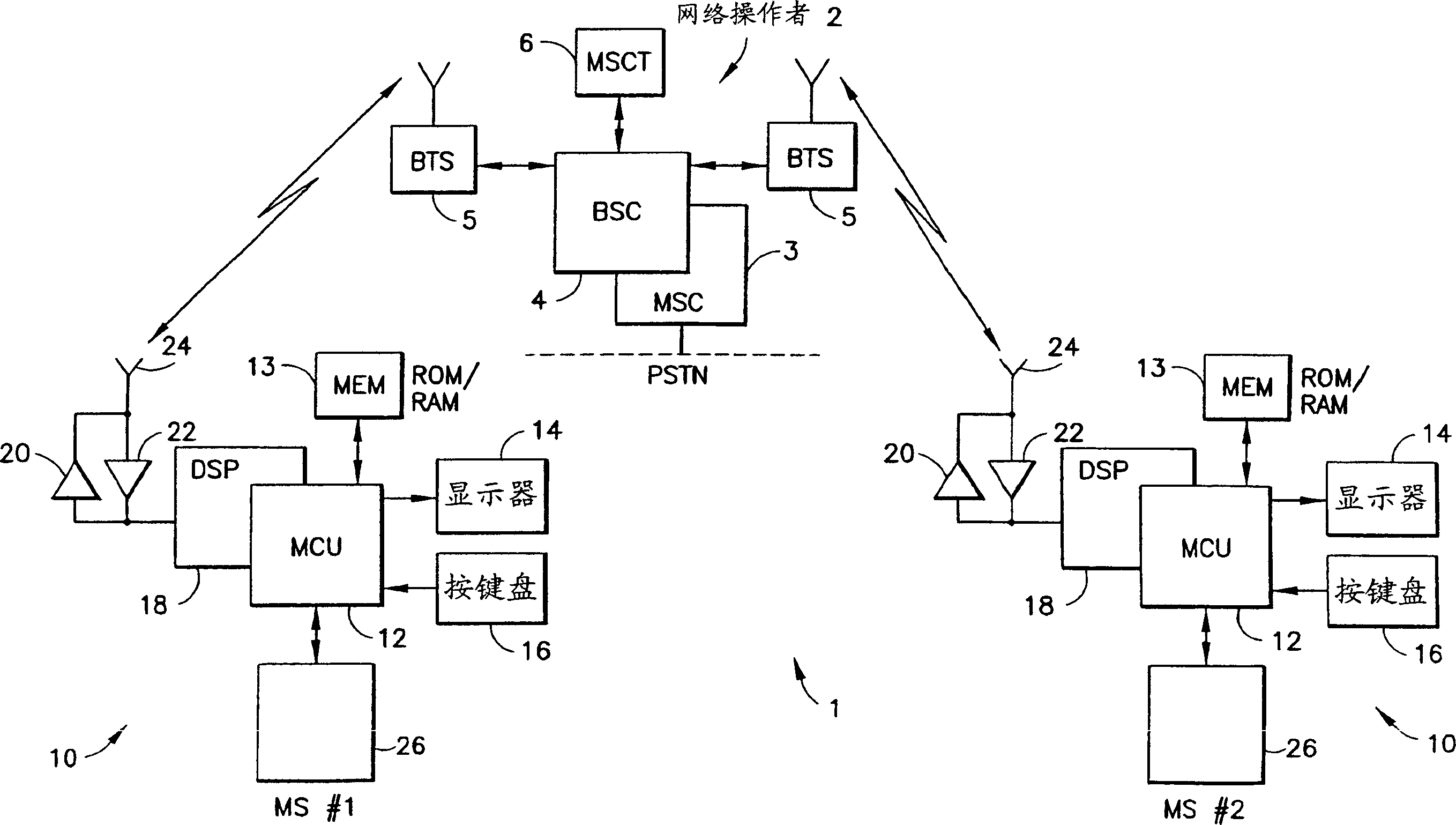

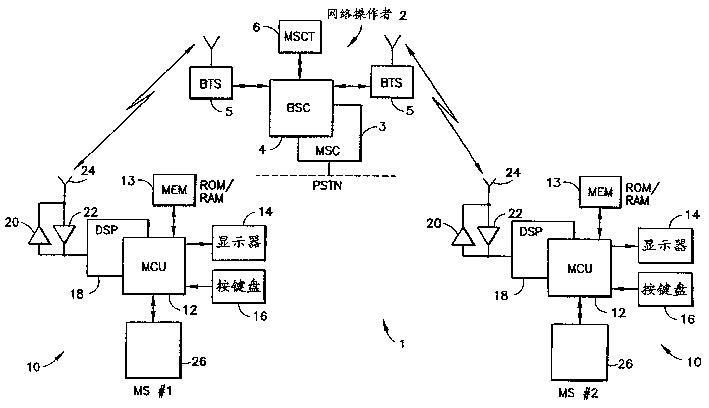

Method and apparatus for performing cell reselection for supporting efficiently hierachical cell structures

InactiveCN1409933ARadio/inductive link selection arrangementsWireless communicationCell EvaluationCell selection

A method for performing a cell reselection in a system comprised of a hierarchy of cells, wherein cells of one layer of the hierarchy have a size that differs from cells of another layer of the hierarchy. The method includes steps of (a) identifying to a user equipment a layer to which individual cells in a neighbor cell list are associated; (b) when performing neighbor cell measurements for reselection purposes, avoiding a measurement of cells in the list that are larger than a current serving cell unless a Cell Selection (S) parameter falls below a search threshold parameter (Ssearch), and is greater than zero; and (c), if S is less than or equal to zero, and no cell reselection to a better cell is in process, beginning a measurement of neighbor cells without regard for their hierarchical level. If the user equipment has made cell reselection to N different cells on the same hierarchical layer within a time Tmax, the user equipment initiates a reselection procedure for larger neighbor cells. This procedure accommodates user equipment that is moving at a relatively high speed through the cells. If the user equipment locates a larger cell, which fulfills cell reselection criteria Sn > 0 and Qn > Qs+Qoffsets,n+Qhyst for a period of time Treselection, cell reselection to the larger cell is made. Furthermore, if the user equipment performs a cell reselection to the larger cell, the user equipment does not attempt to reselect to a smaller cell within a time X, unless an immediate cell evaluation is triggered, wherein the time X can be pre-specified, or can be set by the network.

Owner:NOKIA TECHNOLOGLES OY

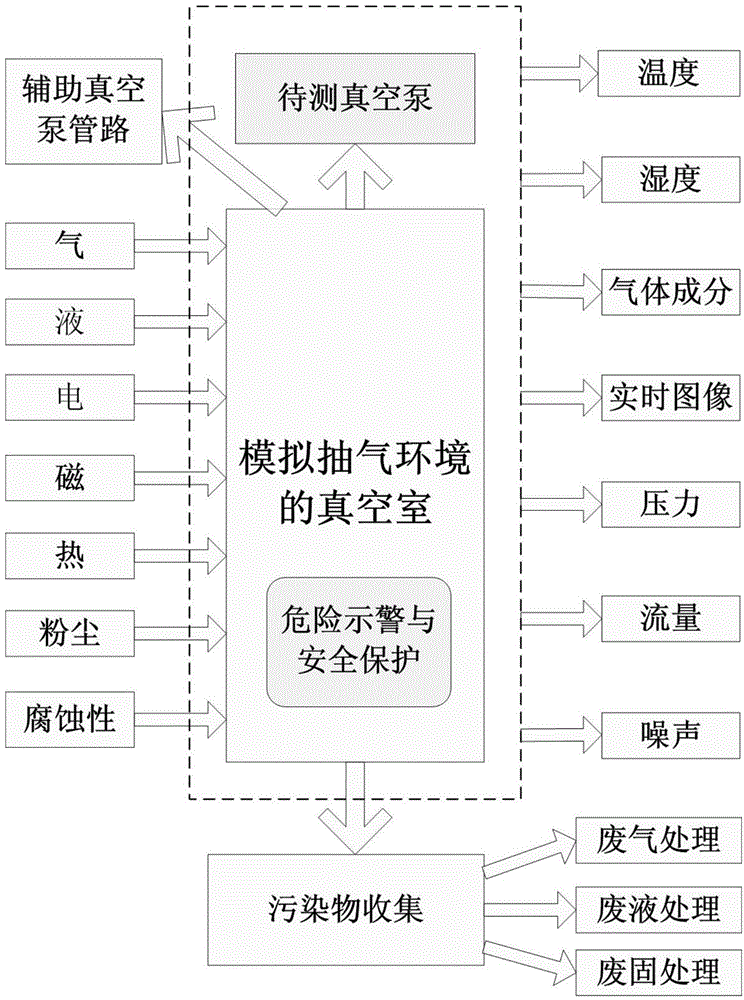

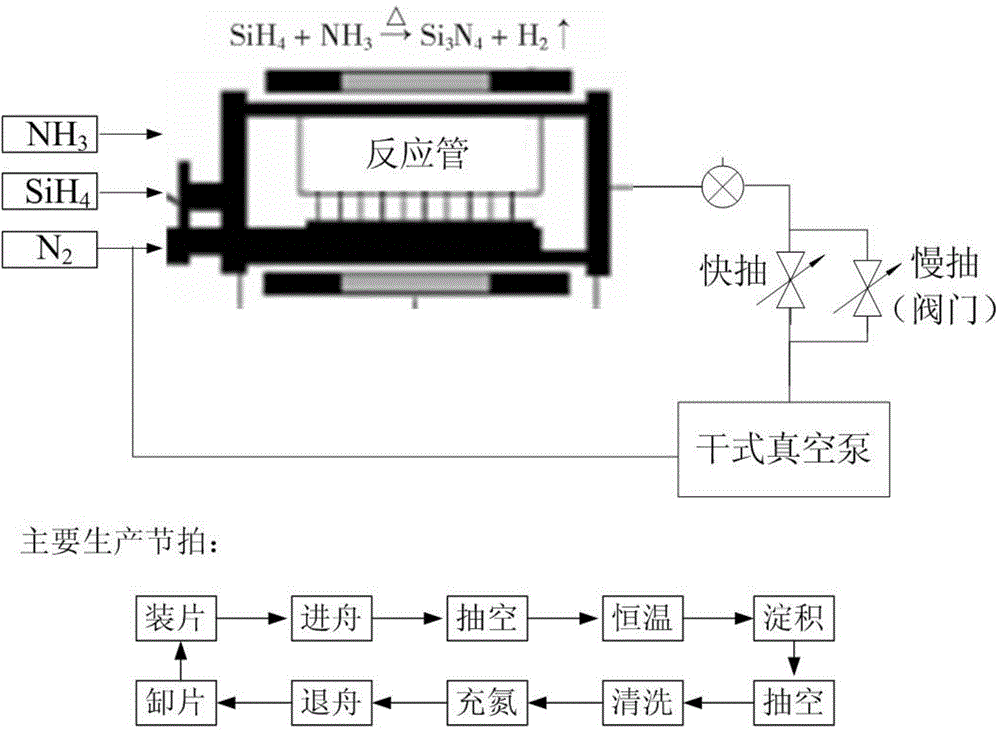

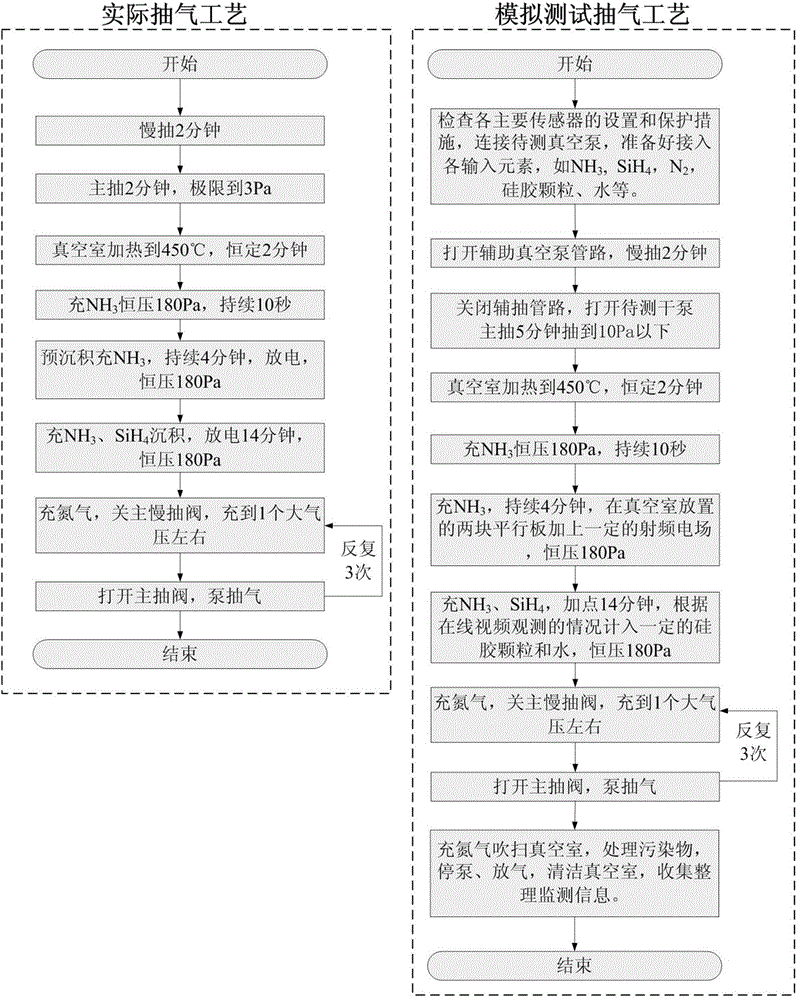

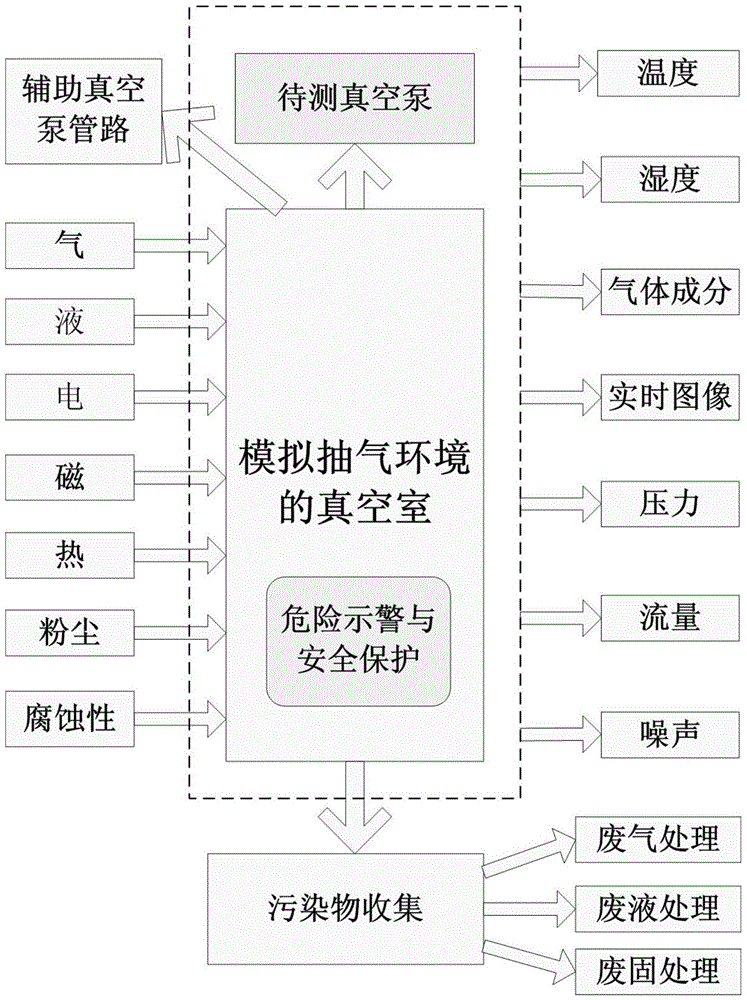

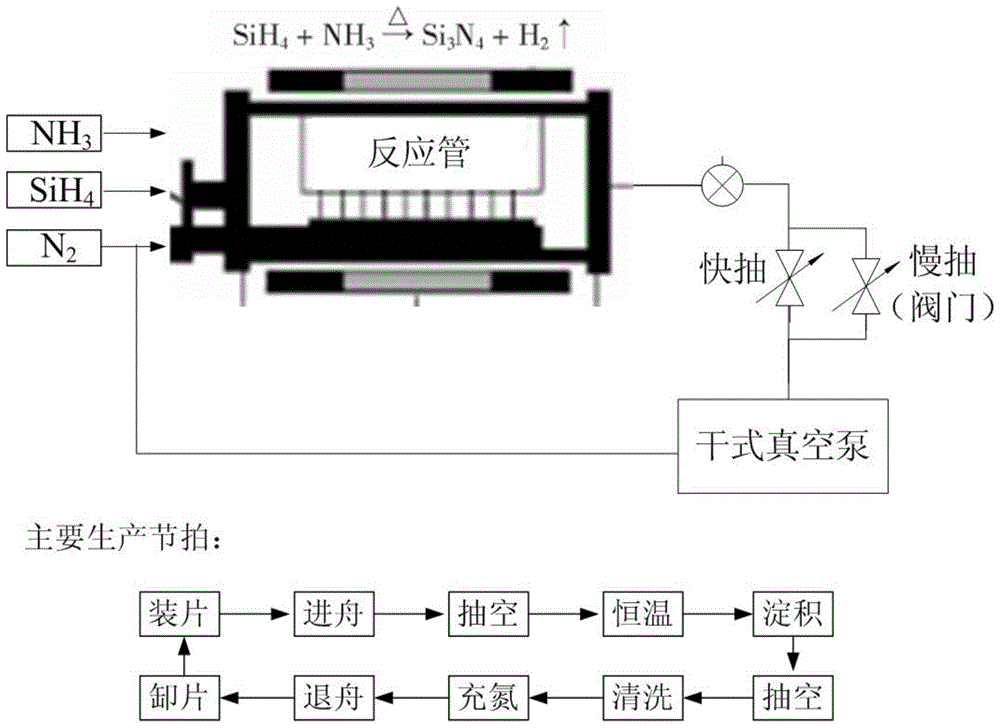

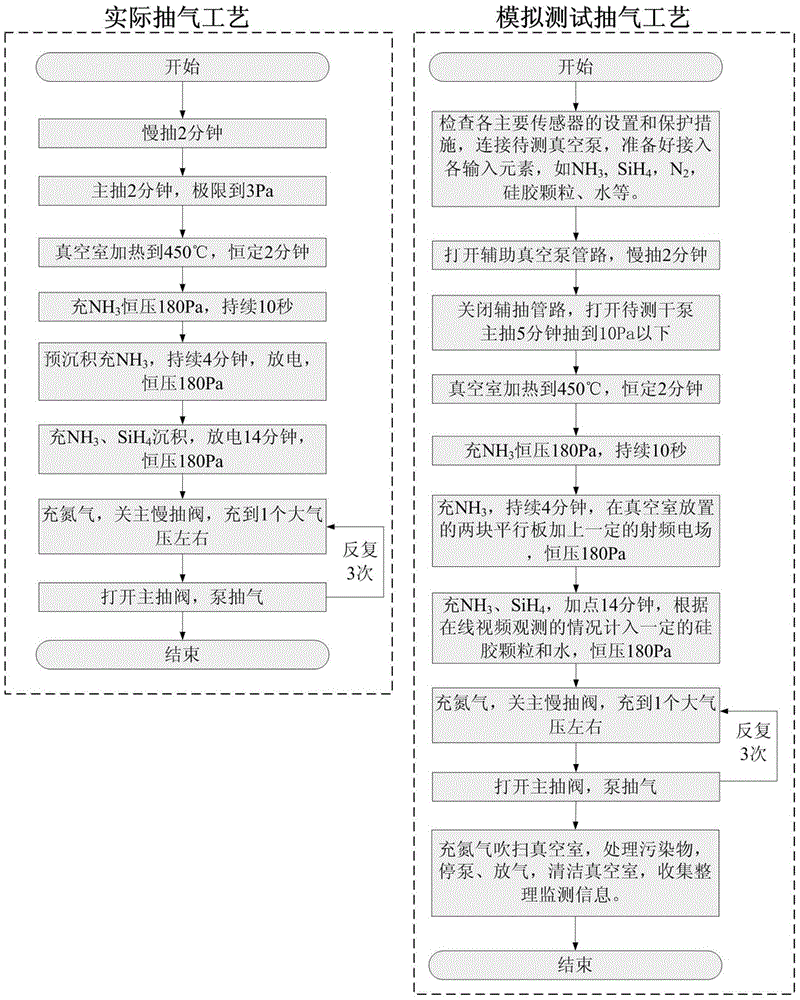

Test method and text system for simulating air exhaust technology of dry vacuum pump

ActiveCN104632604AExtraction process optimizationGuaranteed zero emissionsPump testingPump componentsEtchingEngineering

Disclosed are a vacuum pump air exhaust process simulating and testing method and a testing system. By means of a built simulating vacuum chamber, common elements in various dry-type vacuum pump application environments such as gas, liquid, electricity, magnetism, heat, dust, and corrosion are integrated, various sensors are used to perform feedback on a signal simultaneously having temperature, humidity, gas ingredient, real-time image, pressure, traffic and noise, and multiple control systems are used to perform monitoring, so as to check and improve dry-type vacuum pump air exhaust process adaptation situations. The testing system uses strict contaminant collecting and shuttling treatment, has a danger warning and automatic protecting function system, is characterized by being secure, intelligent, and green and environment-friendly, has good repeatability, and may simulate vacuum pump air exhaust process environments such as cleaning, mildly-polluted, intermediately-polluted and seriously-polluted vacuum environments comprising transfer, physical vapor deposition, chemical vapor deposition, etching, photolithography, chemical engineering, and pharmacy.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

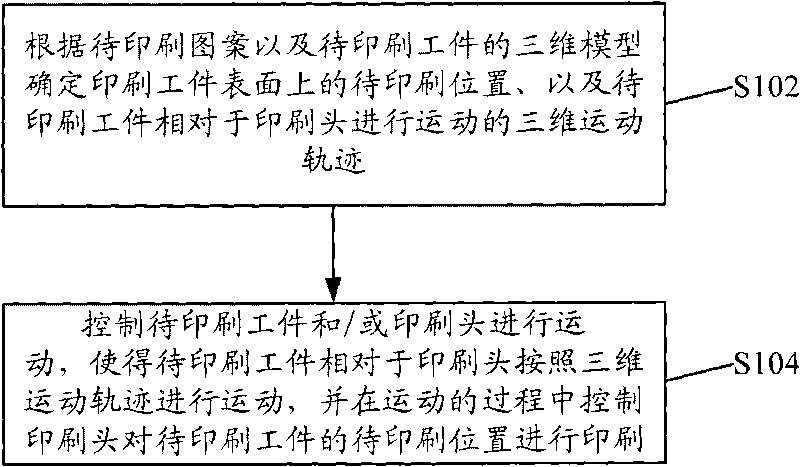

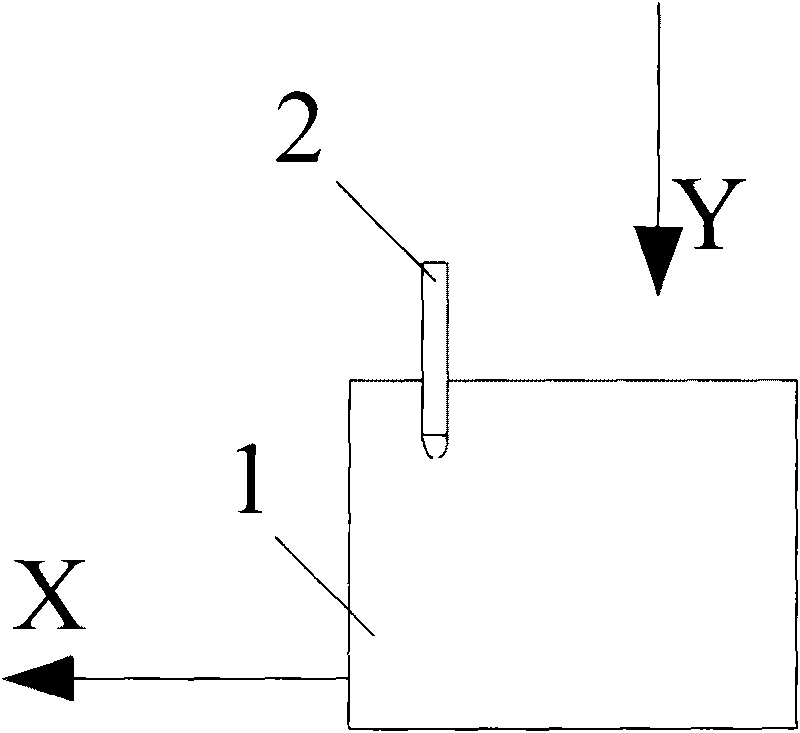

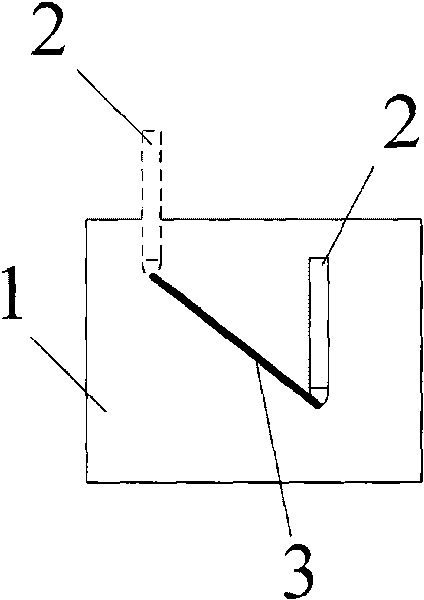

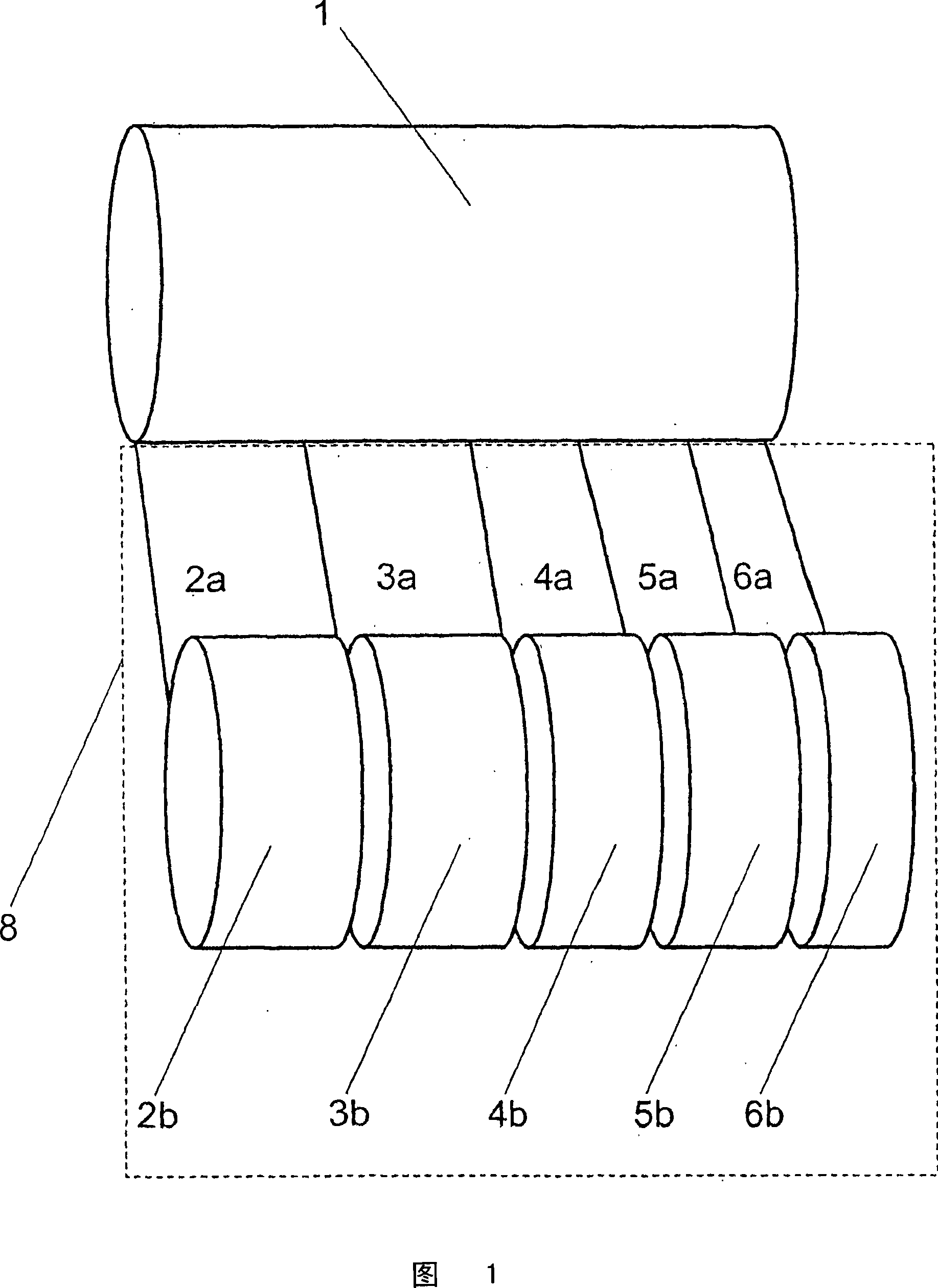

Realization method and device of image printing

The invention discloses a realization method and device of image printing. The method comprises the following steps: determining the position to be printed on the surface of a printing workpiece and the three-dimensional motion track of the workpiece to be printed relative to a print head according to the image to be printed and the three-dimensional model of the workpiece to be printed; controlling the workpiece to be printed and / or the print head to move so that the workpiece to be printed moves along the three-dimensional motion track relative to the print head when the print head is controlled to print at the position to be printed on the surface of the printing workpiece. The method of the invention ensures the change of the relative position between the workpiece and the print head to correspond to the track of the image to be printed by controlling the workpiece and / or print head to perform three-dimensional motion so that the problem that the production efficiency is reduced through non-direct printing can be avoided, the printing process can be applicable to various complicated surfaces and shapes of workpieces, and the printing effect, printing performance and production efficiency can be effectively improved.

Owner:李华容

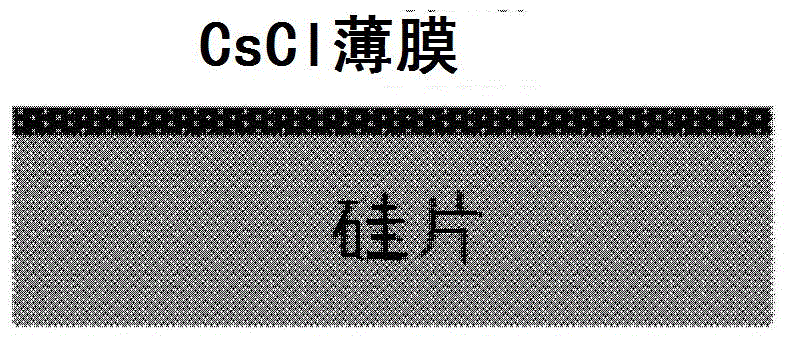

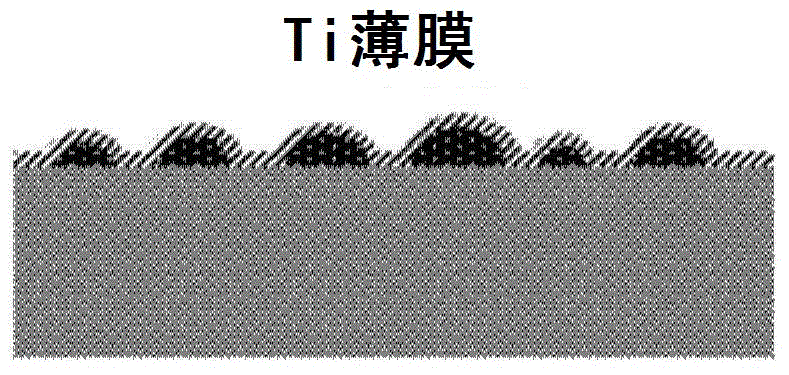

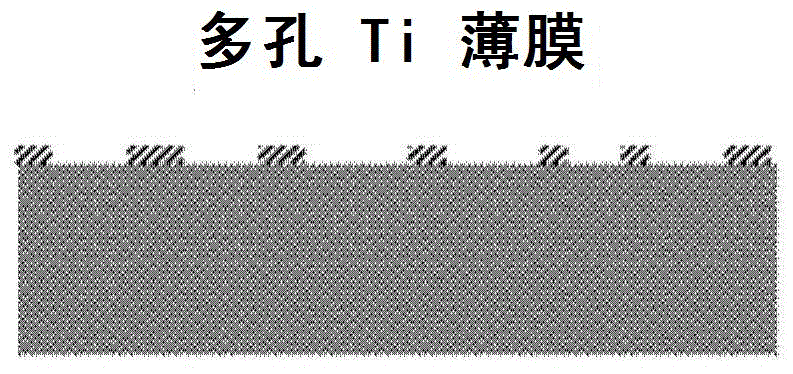

Preparation method for inverted pyramid structure on silicon wafer surface

InactiveCN104538283ASimple manufacturing processReduce manufacturing costSemiconductor/solid-state device manufacturingSemiconductor devicesTitanium metalEvaporation

The invention discloses a preparation method for an inverted pyramid structure on a silicon wafer surface. The method comprises the following steps that a cesium chloride island structure is prepared on the silicon wafer surface; a layer of titanium metal film is evaporated on the silicon wafer surface with the cesium chloride nanometer island structure, a silicon wafer is put into deionized water and ultrasonic exfoliation is carried out on the silicon wafer , the cesium chloride island structure and the titanium metal film on the cesium chloride island structure are removed, and porous titanium film is formed on the silicon wafer surface; anisotropic etching is carried out on the silicon wafer surface by the porous titanium film used as covering film; the porous titanium film on the silicon wafer surface is removed, and the inverted pyramid structure is formed on the silicon wafer surface. The preparation method for the inverted pyramid structure on the silicon wafer surface is accomplished by utilizing the technologies of vacuum cesium chloride film coating, cesium chloride self-assembly, vacuum thermal evaporation metal film coating, exfoliation and wet anisotropic etching, the preparation technology is simplified, the preparation cost is lowered, and the defects that the application is limited on aspects such as large-scale industrialization and nanometer level small scale pyramid array preparation are overcome. The preparation method for the inverted pyramid structure on the silicon wafer surface has low cost and stronger process adaptation performance, and is convenient to promote and apply.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

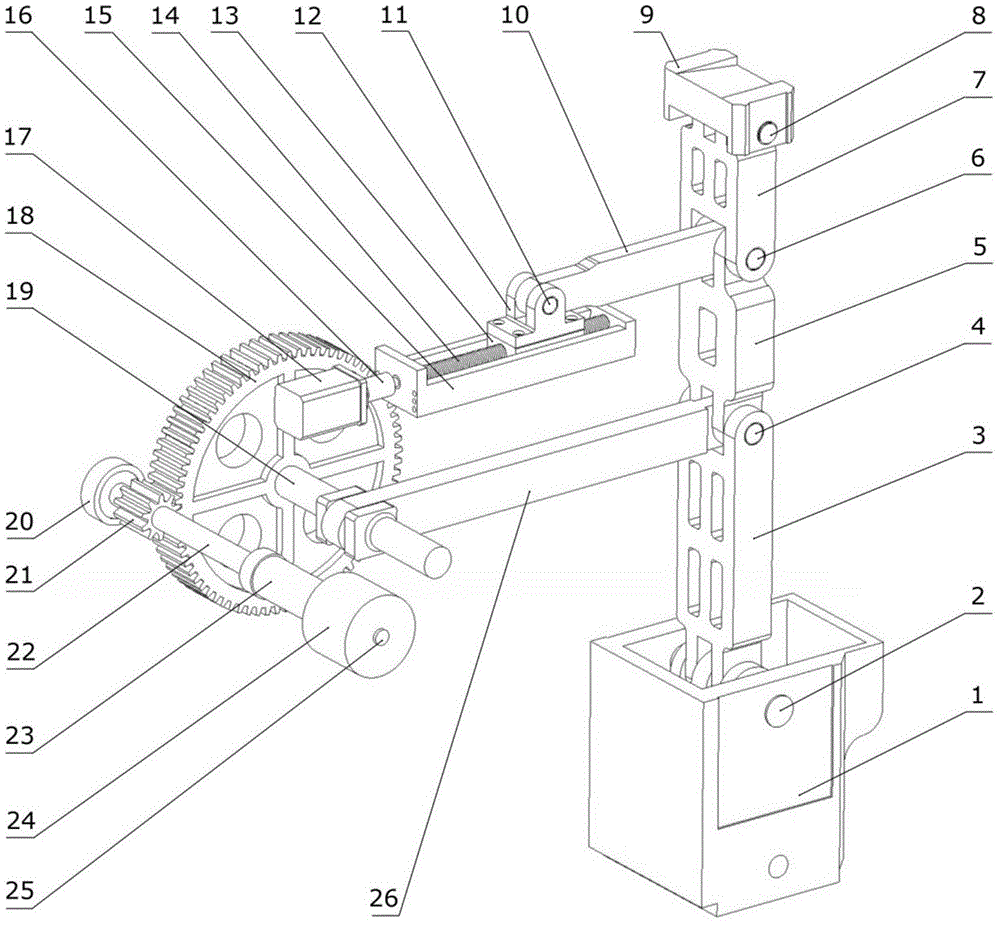

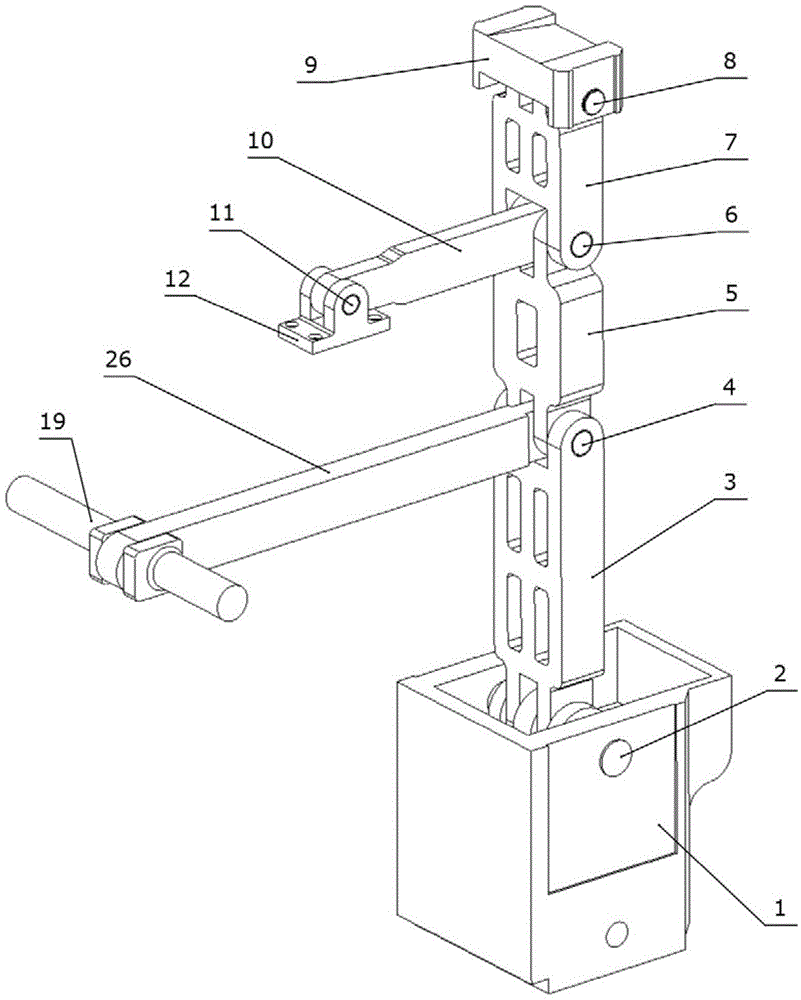

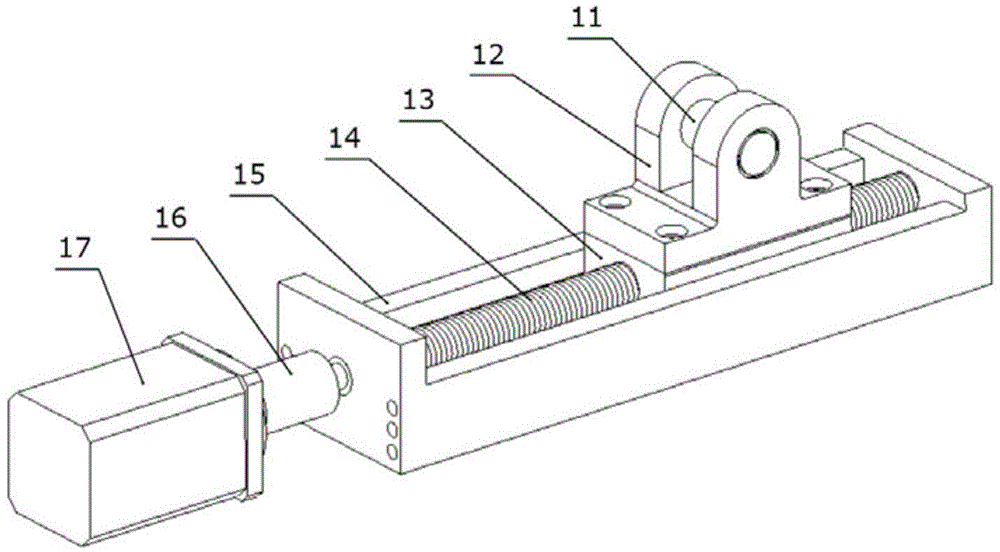

Double-toggle double-motor parallel-drive toggle rod mechanism and control method thereof

ActiveCN104550601AReduce outputGuaranteed non-overlapping collinearityForging press drivesPress ramWork performanceProcess adaptation

The invention discloses a double-toggle double-motor parallel-drive toggle rod mechanism and a control method thereof. The double-toggle double-motor parallel-drive toggle rod mechanism is a two-freedom parallel mechanism including a double-toggle bearing mechanism, an upper toggle regulating mechanism, a lower toggle regulating mechanism; the double-toggle bearing mechanism comprises two toggles; the upper toggle regulating mechanism and the lower toggle regulating mechanism are distributed at the two ends of the double-toggle bearing mechanism, and are respectively connected with two toggles in the double-toggle bearing mechanism through a drive mechanism and a transmission mechanism to drive two toggles in the double-toggle bearing mechanism to move. According to the double-toggle double-motor parallel-drive toggle rod mechanism, contradiction that a reinforcing effect of a servo mechanical press working mechanism and stroke of a slide block are clamped with each other is solved, biggest stroke of the slide block can be obtained, the servo motor power capacity and the manufacturing cost of the press are reduced; the slide block movement speed, the biggest stoke of the slide block and the slide block lower dead point are adjustable; working performance and process adaptation of the servo press are improved.

Owner:SHUNDE POLYTECHNIC +1

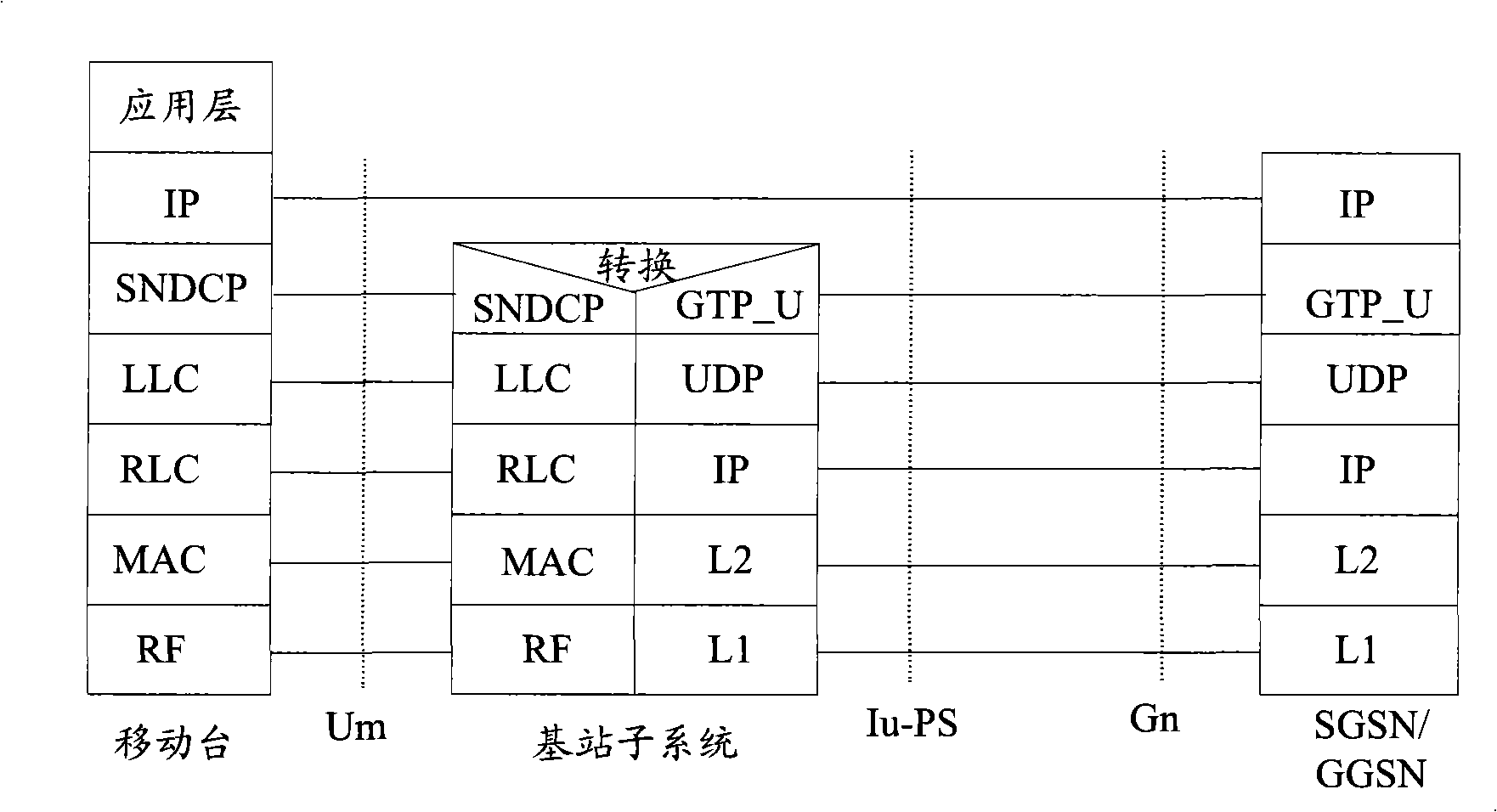

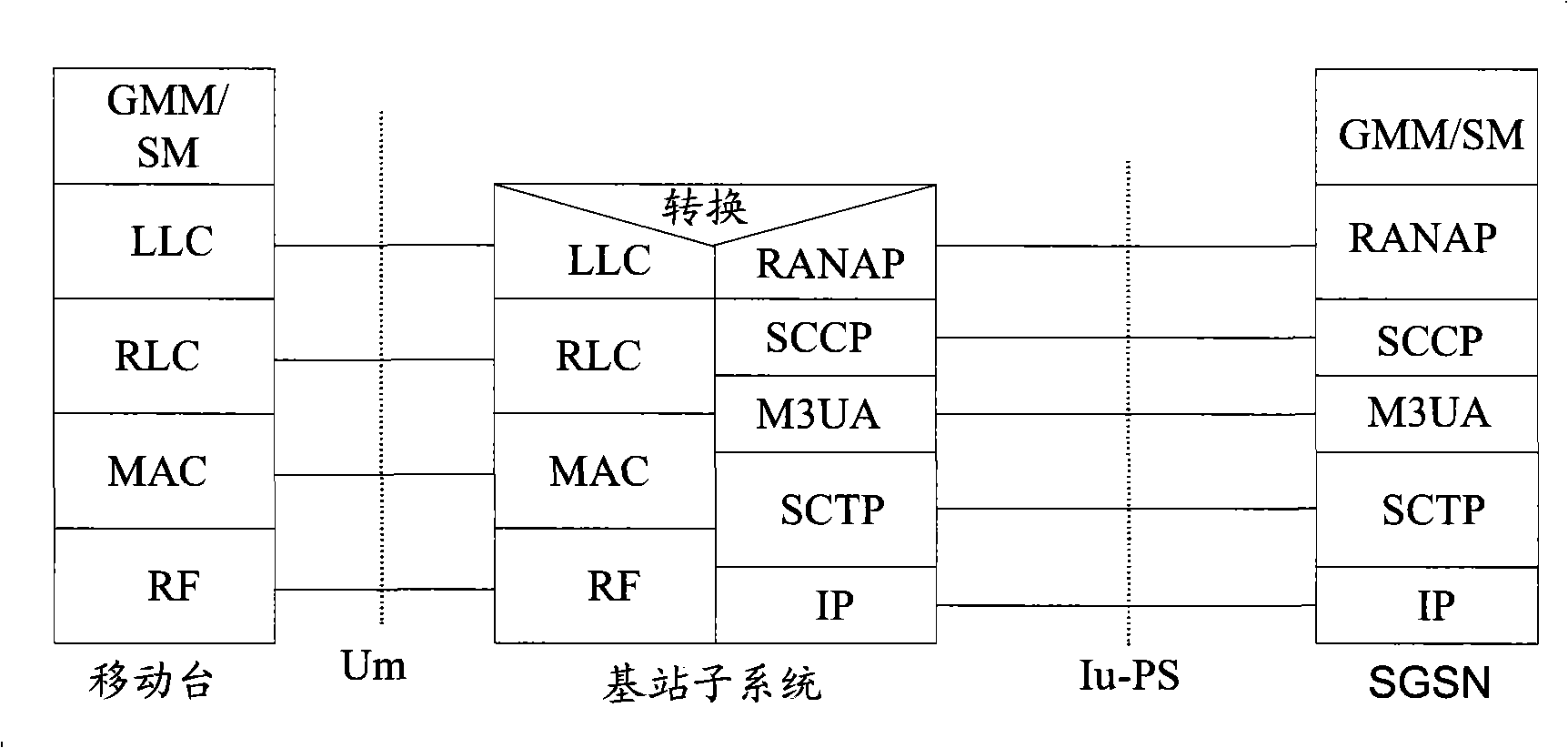

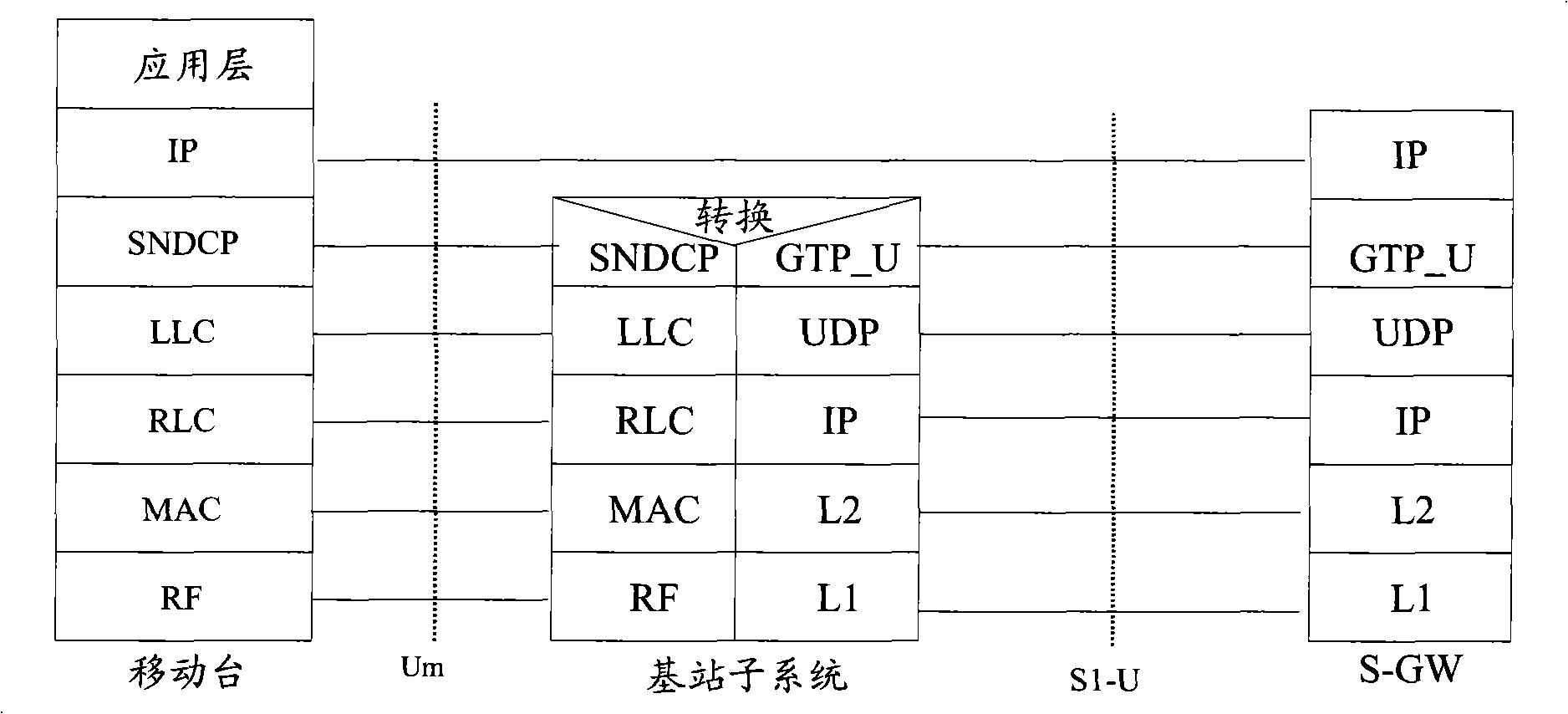

Base station subsystem context uploading method, downloading method and device

InactiveCN101272541ARadio/inductive link selection arrangementsData switching networksComing outGeneral Packet Radio Service

The invention discloses an upload method for the context of a base station subsystem which includes: a message which carries the context of the base station subsystem is constructed and the message which carries the context of the base station subsystem is sent to a general packet radio services support node or a mobile management entity. The invention also discloses a download method for the context of the base station subsystem which includes: the message which carries the context of the base station subsystem which is sent out by a source enhanced base station subsystem is received, the carried context of the base station subsystem thereof is stored, the context request of the base station subsystem which is sent out by a target enhancing base station subsystem is received and the message which carries the context of the base station subsystem is sent out to the target enhancing base station subsystem after the context request of the base station subsystem which is sent out by a target enhancing base station subsystem is received. The invention also discloses a corresponding device. By adopting the invention, LLC and SNDCP move downward to a BSS and come out of an Iu-PS interface to successively accomplish the process adaptation of Cell Update and Routeing Area Update.

Owner:HUAWEI TECH CO LTD

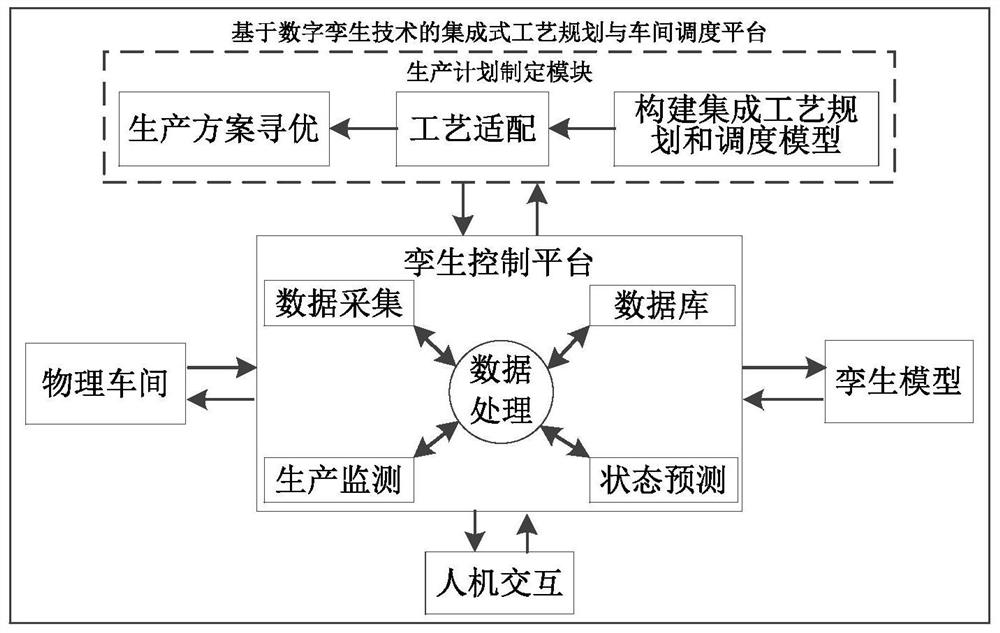

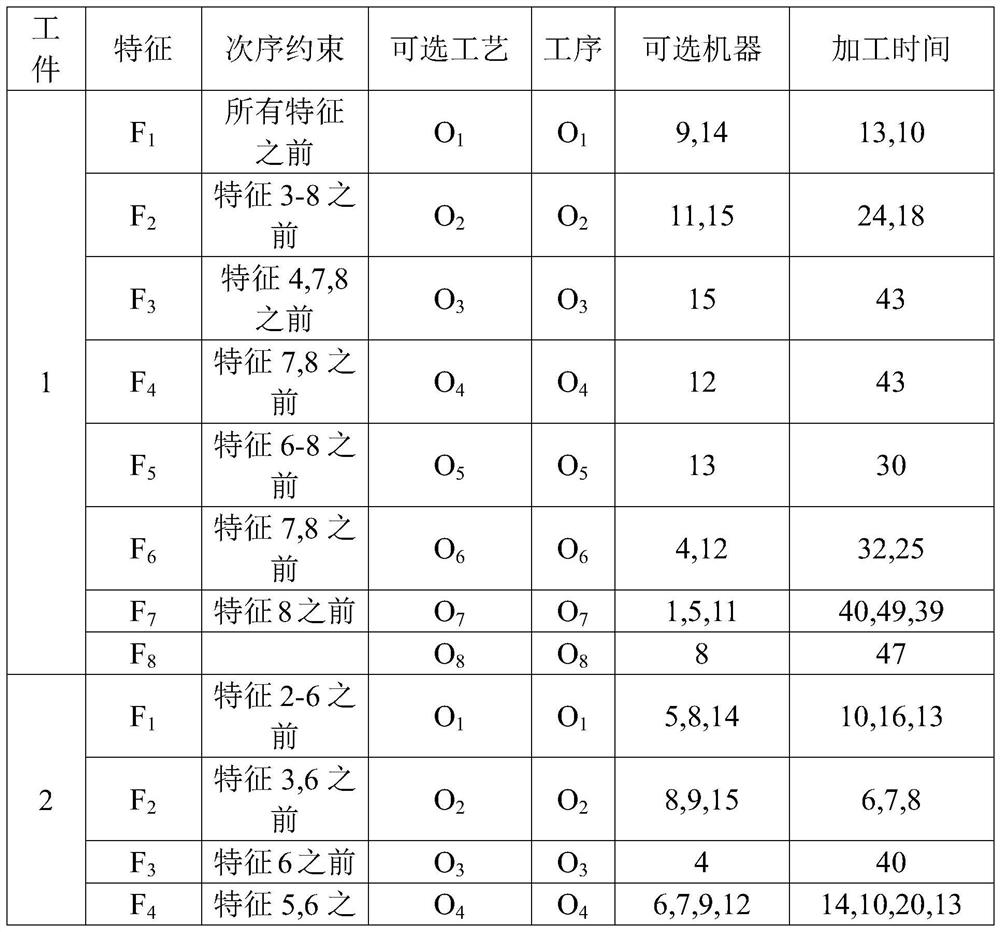

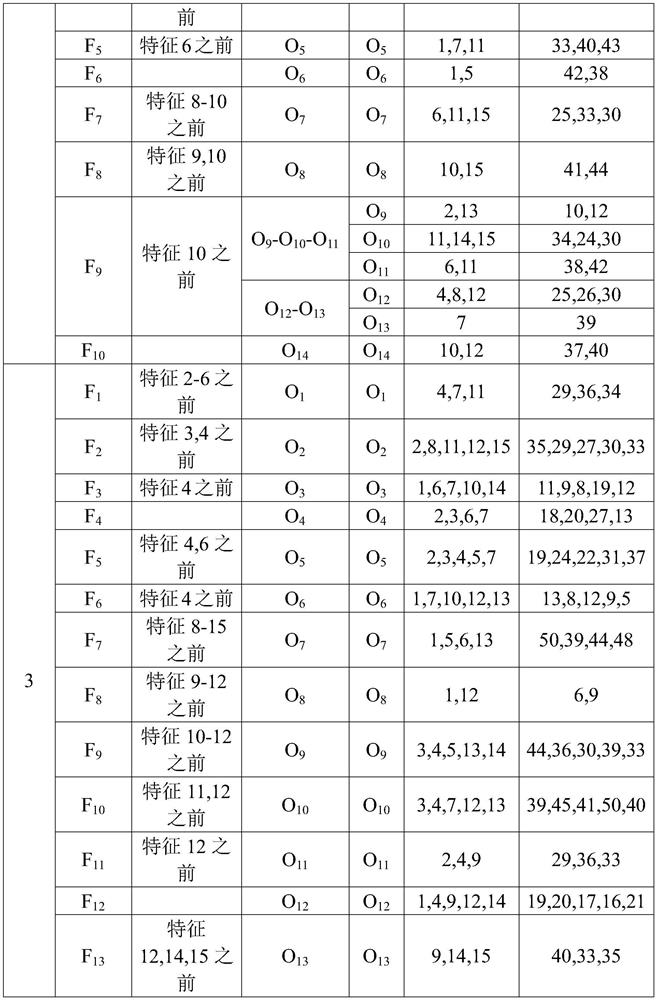

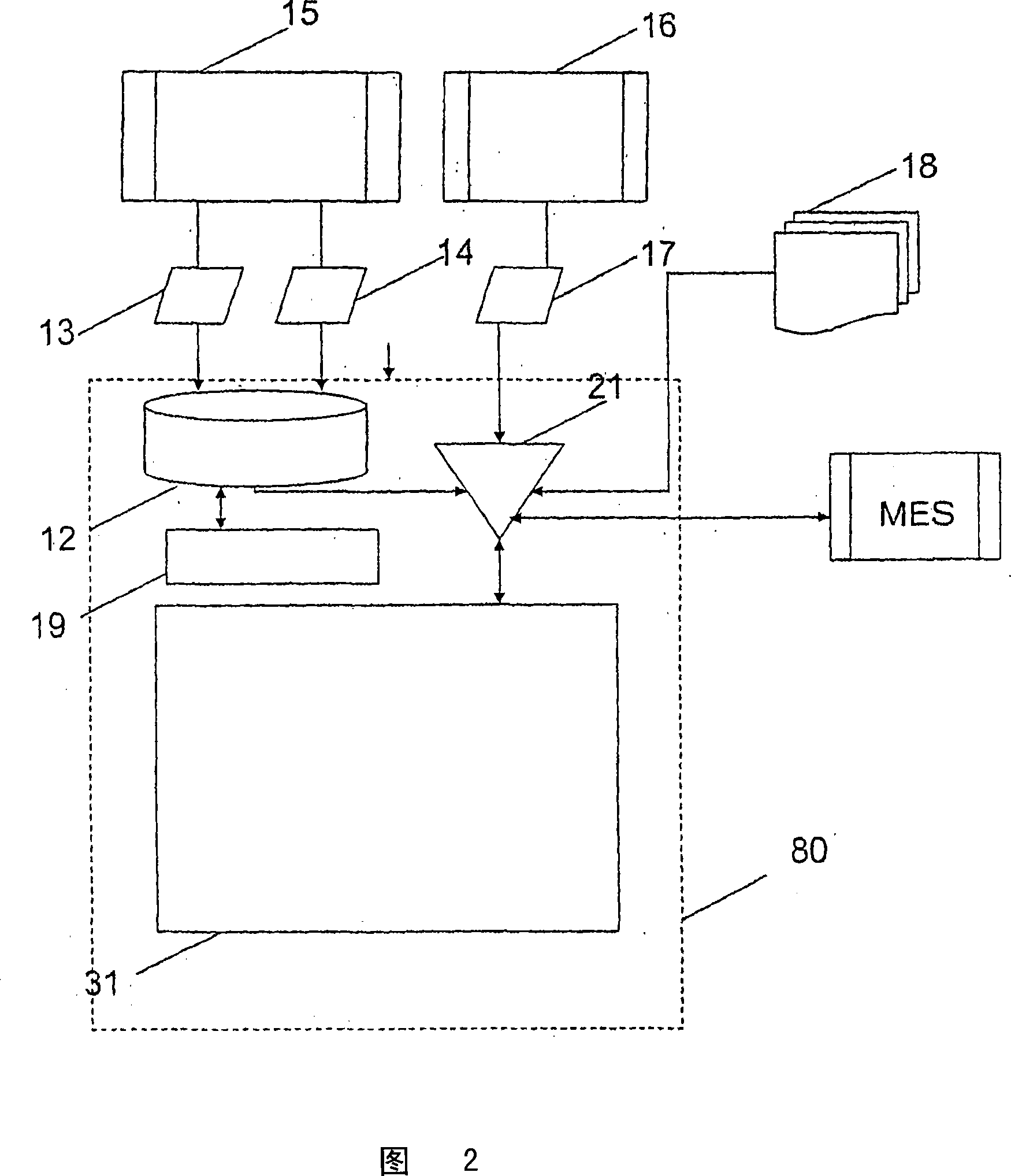

IPPS problem solving method under uncertain disturbance based on digital twinning

ActiveCN113867299AReduce the impactImprove stabilityTotal factory controlProgramme total factory controlState predictionMathematical model

The invention provides an IPPS problem solving method under uncertain disturbance based on digital twinning. According to the method, man-machine interaction, a physical workshop, a twinborn model, a twinborn control platform and a production plan making module are included, wherein the twinborn control platform is composed of a data acquisition part, a data processing part, a state prediction part, a production detection part, a database part and the like. The production plan making comprises the functions of integrated process planning, dynamic construction of a workshop scheduling model, process adaptation and production plan optimization. Thus, the digital twinning technology can be fully utilized to predict the workshop state, and the optimization target of production is dynamically determined, so that a dynamic mathematical model of integrated process planning and workshop scheduling is constructed in real time; meanwhile, the multi-flexibility characteristics of integrated process planning and workshop scheduling problems are considered, process adaptation is provided, task requirements and workshop current situations can be accurately docked and machining processes can be matched, so that the production efficiency of workshops and the stability of the production process are improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Substrate coated with silica-containing film with low-dielectric constant

InactiveUS6893726B2Low dielectric constantMoisture adsorptivityLayered productsSemiconductor/solid-state device manufacturingSilicon dioxideCarbon atom

A coating liquid for forming a silica-containing film with a low-dielectric constant which enables formation of low-density film having a dielectric constant as low as 3 or less and having excellent resistance to oxygen plasma and process adaptation but also in the adhesion to a substrate and film strength. A substrate coated with the silica-containing film having the above characteristics, obtained by the use of the above coating liquid. The coating liquid for forming a silica-containing film with a low-dielectric constant comprises a polymer composition mainly constituted by a polysiloxane and a readily decomposable resin, said polysiloxane being a reaction product between fine particles of silica and a hydrolyzate of at least one alkoxysilane represented by the following formula (I): XnSi(OR)4-n, wherein X represents a hydrogen atom, a fluorine atom, an unfluorinated or fluorinated alkyl group of 1 to 8 carbon atoms, an aryl group or a vinyl group; R represents a hydrogen atom, an alkyl group of 1 to 8 carbon atoms, an aryl group or a vinyl group; and n is an integer of 0 to 3.

Owner:JGC CATALYSTS & CHEM LTD

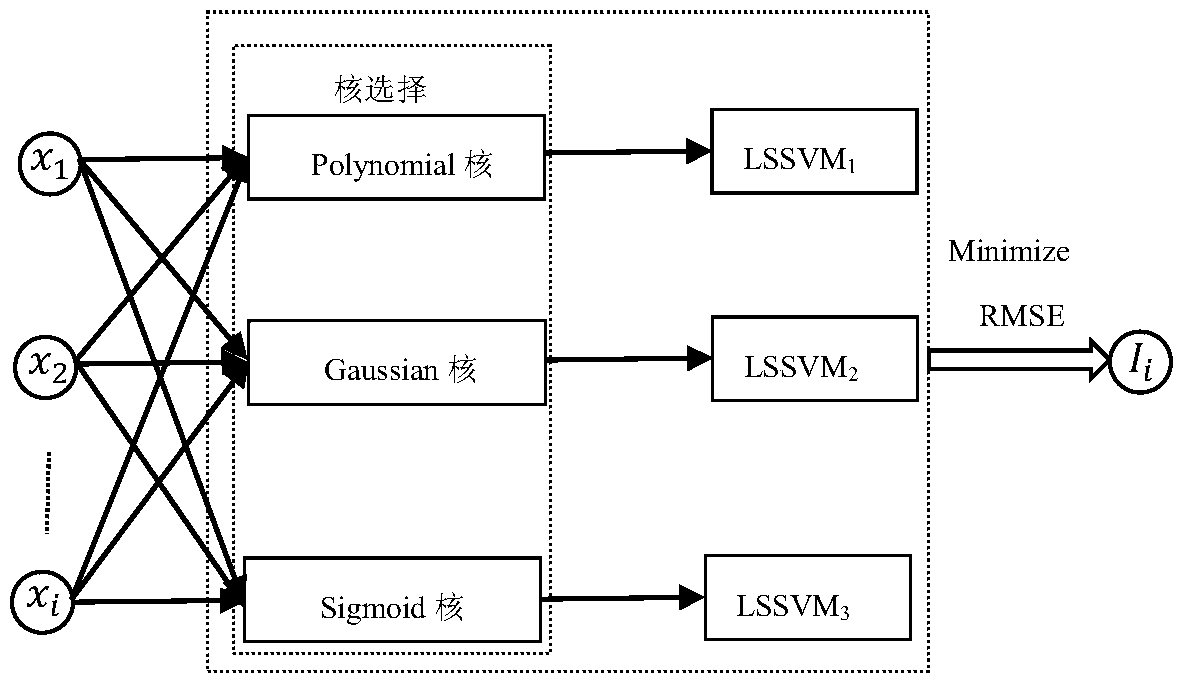

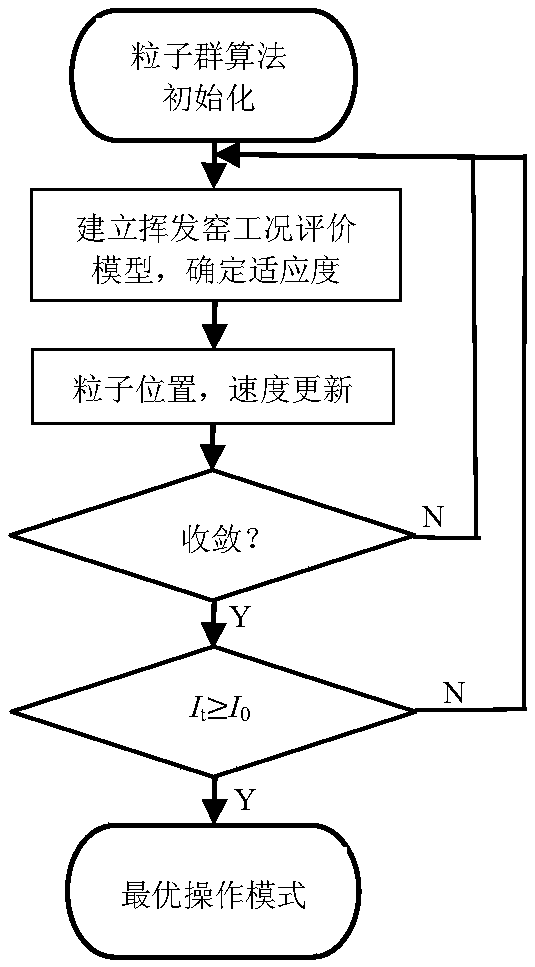

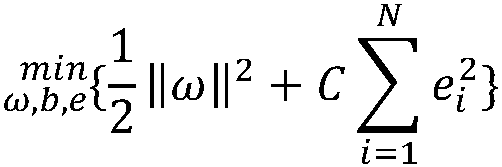

A method for optimizing the operating mode of a volatile kiln by combining least square support vector machine regression and particle swarm optimization

ActiveCN109034523AIncreased level of energy saving and emission reductionResourcesComplex mathematical operationsInstabilityLeast squares support vector machine

In order to solve the problem that it is hard to obtain the optimized operating mode of the volatile kiln, which leads to the fluctuation of the economic index in the production process and the instability of the operation state, the invention provides a method for optimizing the operating mode of the volatile kiln by combining the least square support vector machine regression and the particle swarm optimization. The invention utilizes a multi-objective optimization method based on a particle swarm algorithm to find an optimal operation mode of a volatile kiln in order to optimize product quality, energy consumption and harmful gas emission process indexes of the volatile kiln. Aiming at the problem that the fitness value cannot be obtained in the process of optimization, according to theinput conditions and current state of the volatile kiln, the evaluation model of the working condition of the volatile kiln based on the least square support vector machine regression is establishedto predict the process index value of the volatile kiln, so as to obtain the corresponding fitness value. The method provided by the invention is favorable for improving the energy saving and emissionreduction level in the production process of the volatile kiln.

Owner:HUNAN UNIV OF TECH

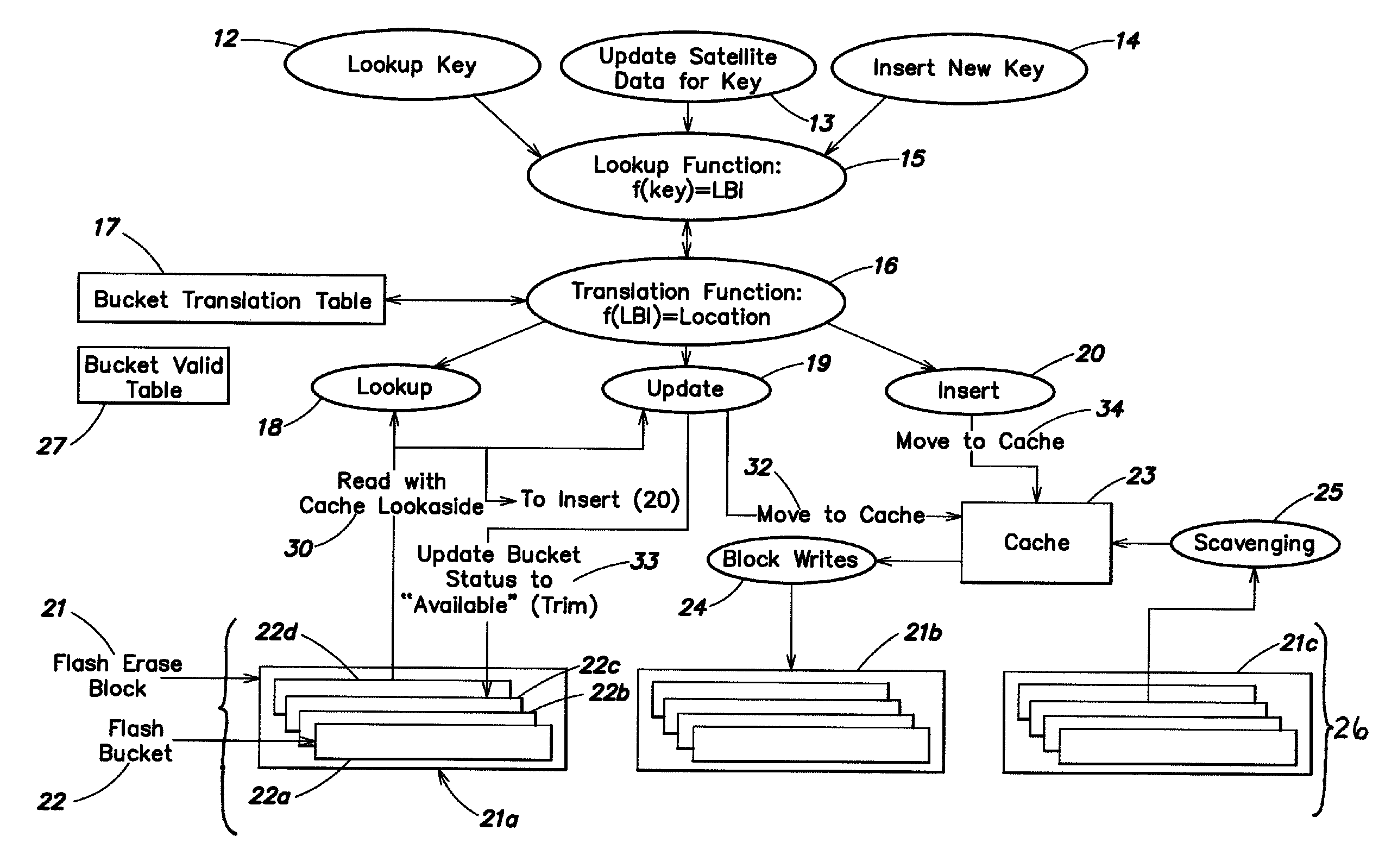

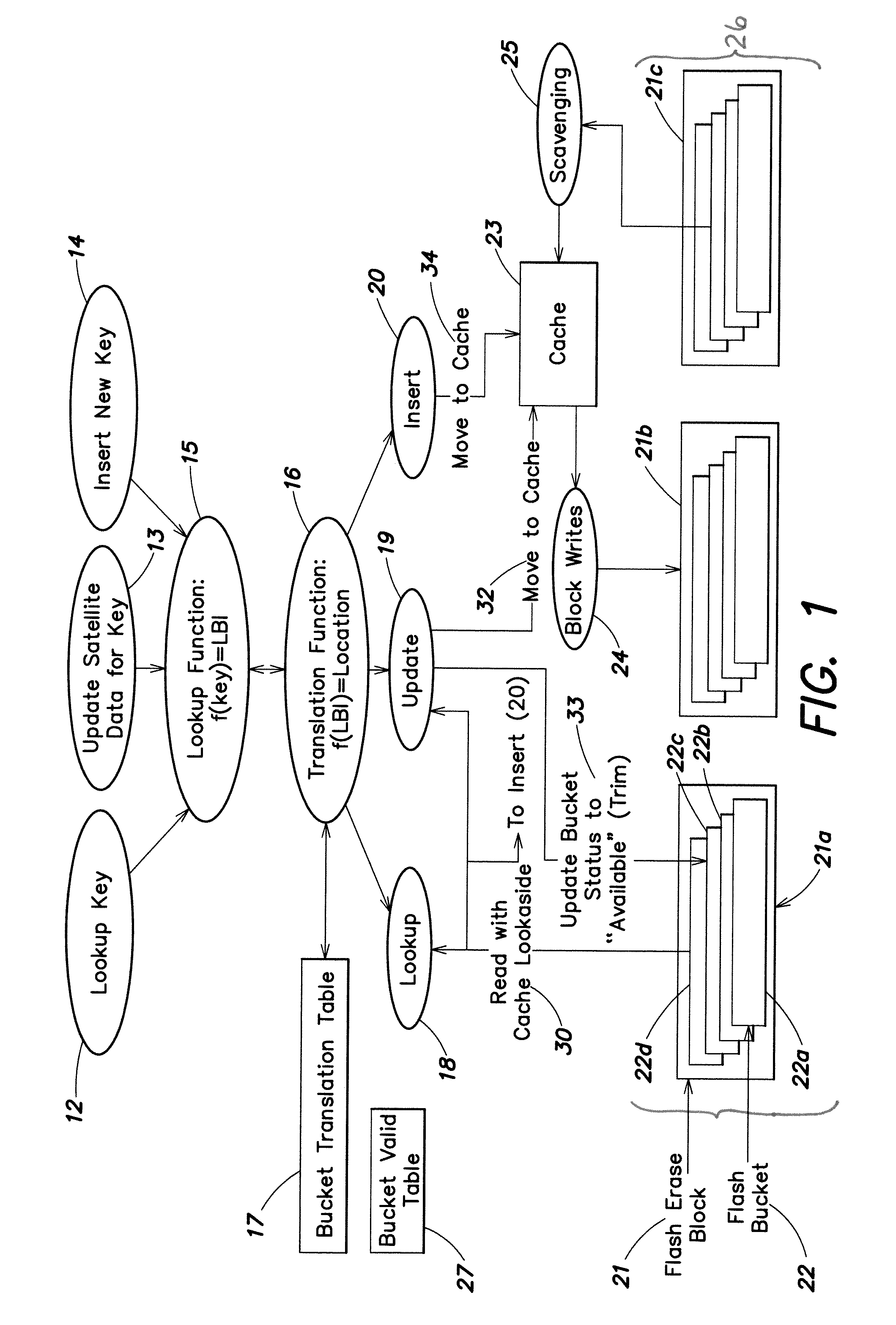

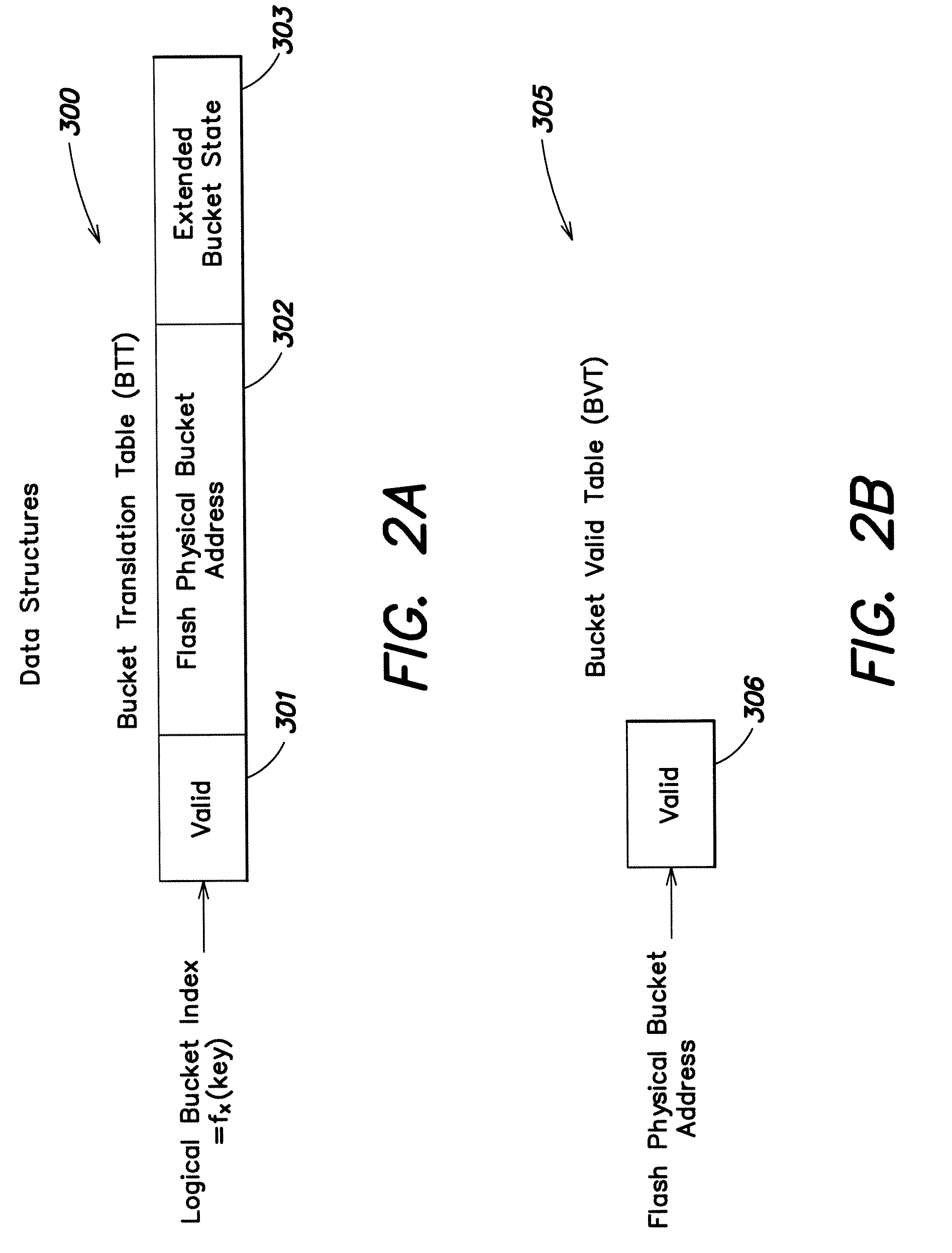

Method of adapting a uniform access indexing process to a non-uniform access memory, and computer system

ActiveUS8880544B2Memory architecture accessing/allocationDigital data processing detailsTraffic capacityRandom access memory

Method and apparatus for constructing an index that scales to a large number of records and provides a high transaction rate. New data structures and methods are provided to ensure that an indexing algorithm performs in a way that is natural (efficient) to the algorithm, while a non-uniform access memory device sees IO (input / output) traffic that is efficient for the memory device. One data structure, a translation table, is created that maps logical buckets as viewed by the indexing algorithm to physical buckets on the memory device. This mapping is such that write performance to non-uniform access SSD and flash devices is enhanced. Another data structure, an associative cache is used to collect buckets and write them out sequentially to the memory device as large sequential writes. Methods are used to populate the cache with buckets (of records) that are required by the indexing algorithm. Additional buckets may be read from the memory device to cache during a demand read, or by a scavenging process, to facilitate the generation of free erase blocks.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

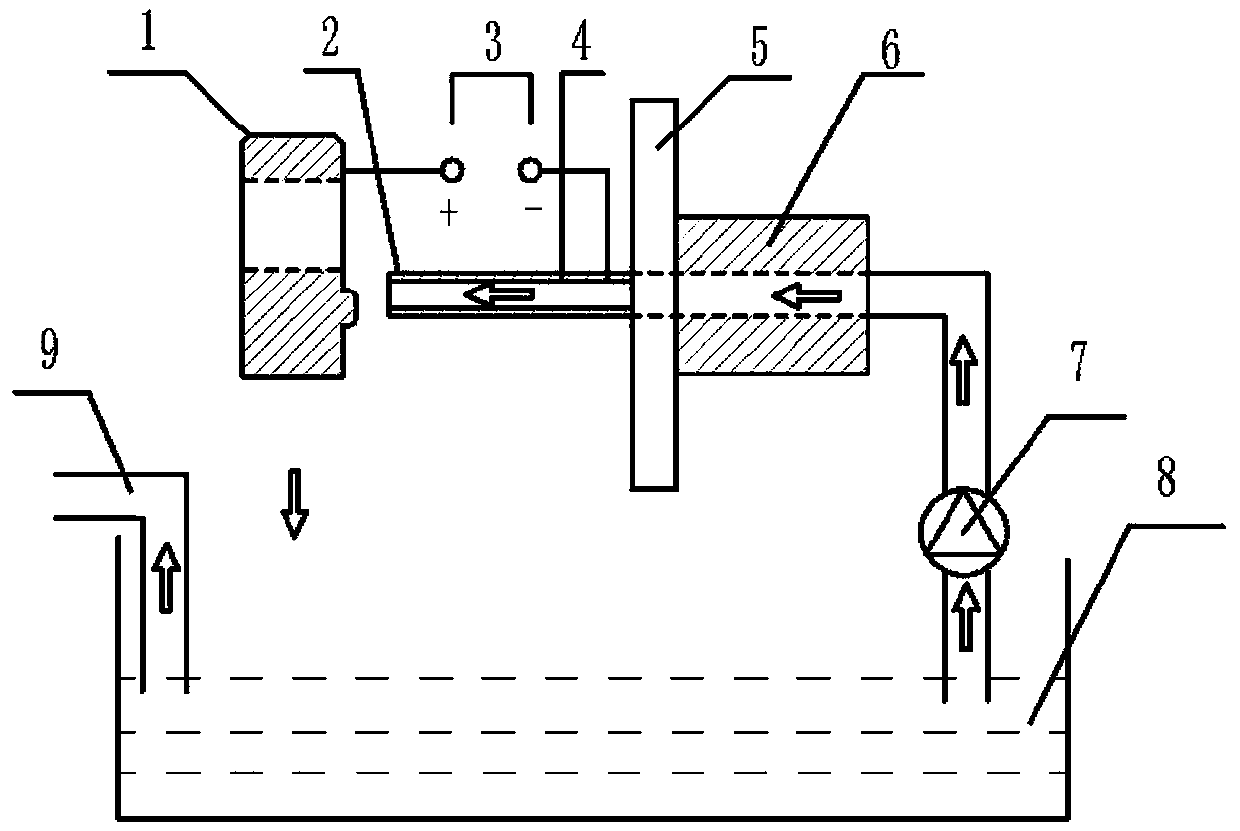

Local micro-arc oxidation device and method for titanium alloy workpieces

InactiveCN110565147AWide range of process adaptationGood masking effectSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a local micro-arc oxidation device and method for titanium alloy workpieces, and belongs to the technical field of titanium alloy surface treatment. The device comprises a mobile micro-arc oxidation power supply, to-be-machined workpieces, a stainless steel cathode tube, an oxidation tank, a solution circulation recovery device and a solution cooling system. The device andmethod have the beneficial effect that firstly, a region where micro-arc oxidation is not needed is shielded through the ink during use, then a local micro-arc oxidation process is used for repairingtreatment, the electric fields of the surfaces of the workpieces are restrained through the tubular stainless steel cathode tube to realize local micro-arc oxidation control on the surface of the titanium alloy, solution flows through the surfaces of the to-be-machined workpieces through a tubular stainless steel cathode port, then the solution flows back to the oxidation groove, shapes and oxidation parts of the workpieces are not explicitly required, and the process adaptation range is wide.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

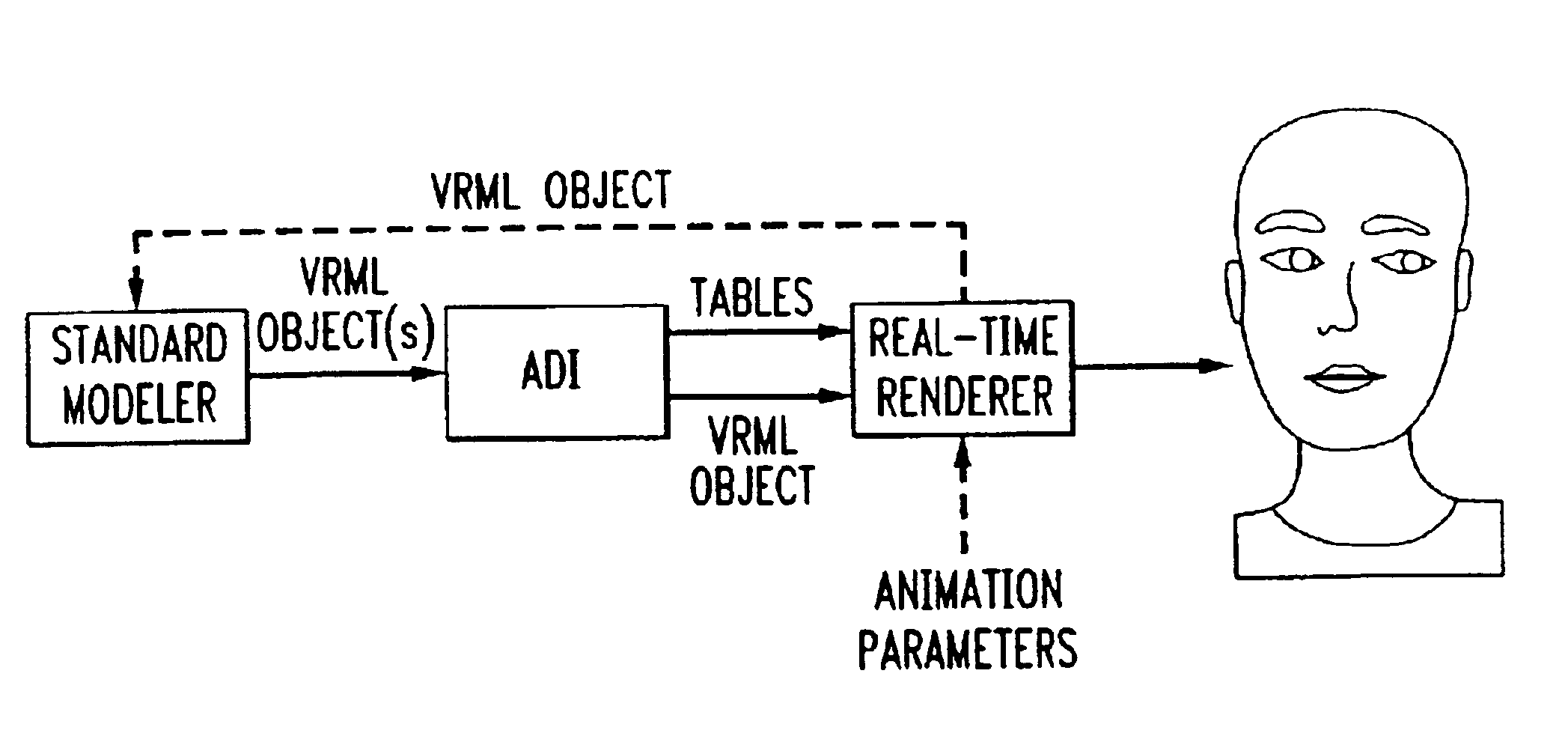

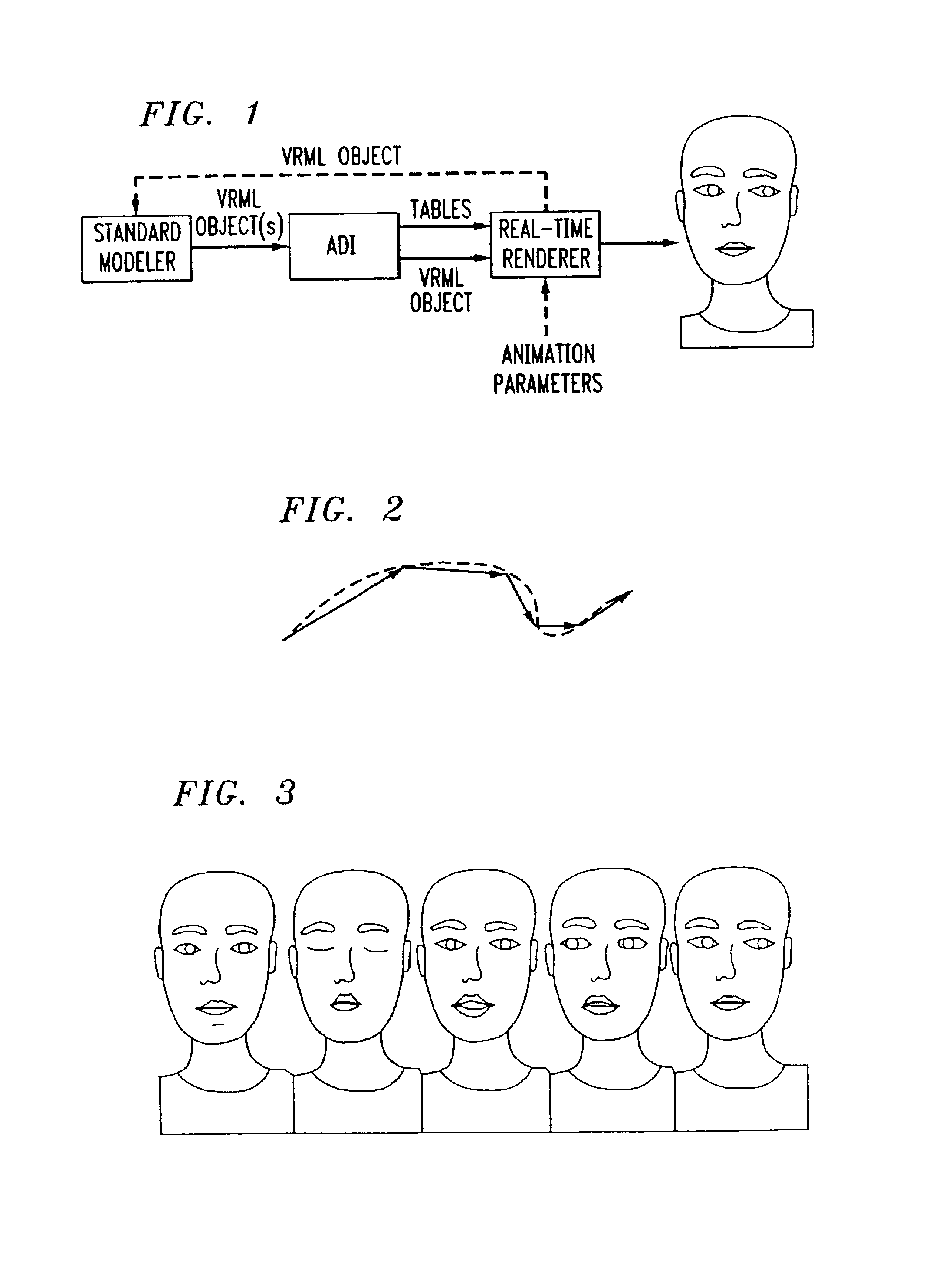

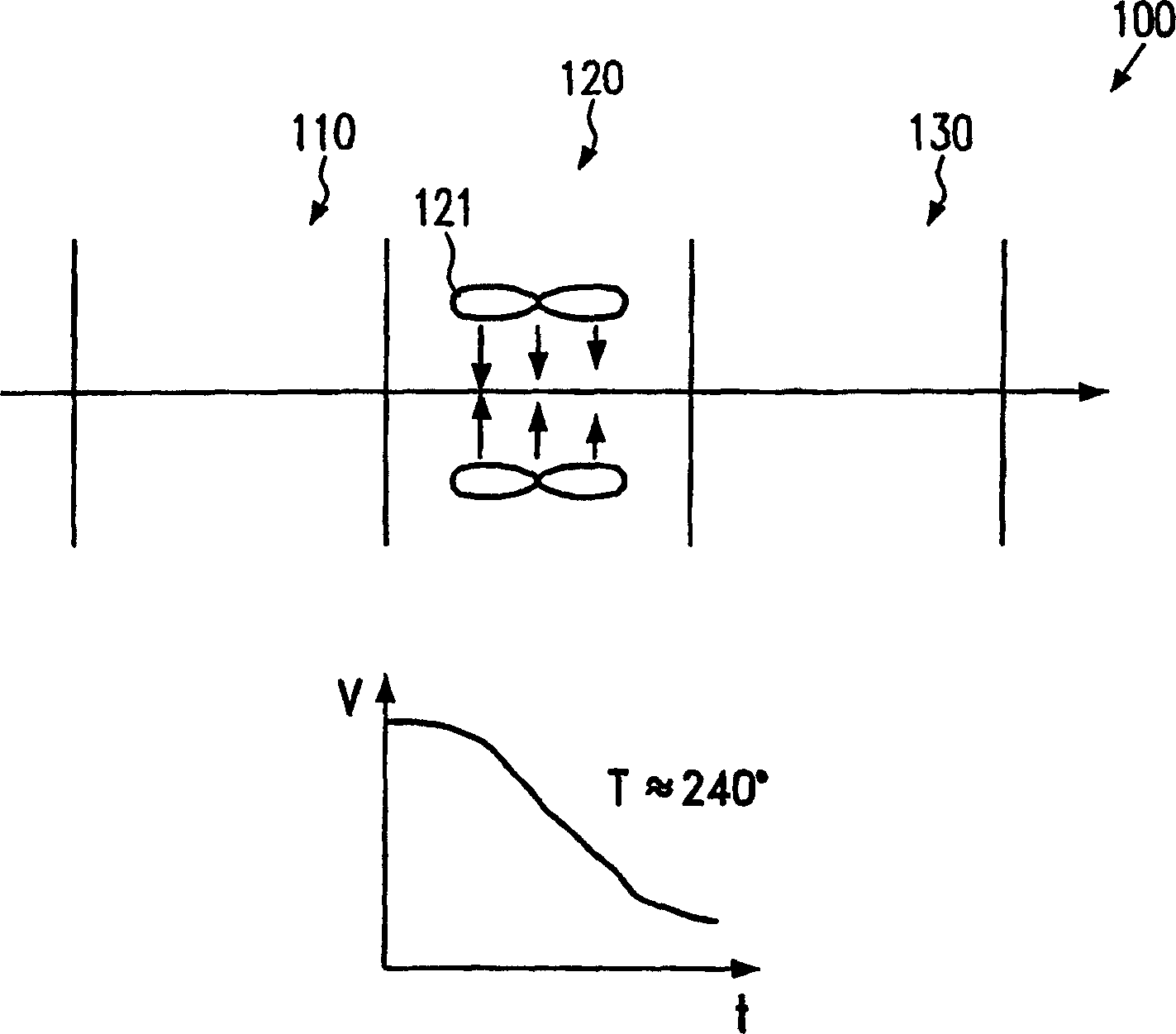

Method for defining MPEG 4 animation parameters for an animation definition interface

InactiveUS6970172B2Easy and inexpensive implementationInexpensive and easily followed methodImage codingAnimationAnimationProcess adaptation

A process is defined for the rapid definition of new animation parameters for proprietary renderers. The process accommodates the peculiarities of proprietary models. In a first step, a proprietary model is animated in a standard modeler and the animated models are saved as VRML files. A converter is used to extract the meaning of a newly defined animation parameter by comparing two or more of the VRML files. Thus, the output of this process is the model and a table describing the new animation parameter. This information is read by the renderer and used whenever the animation parameter is required. The process can easily be used to generate new shapes from the original model.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

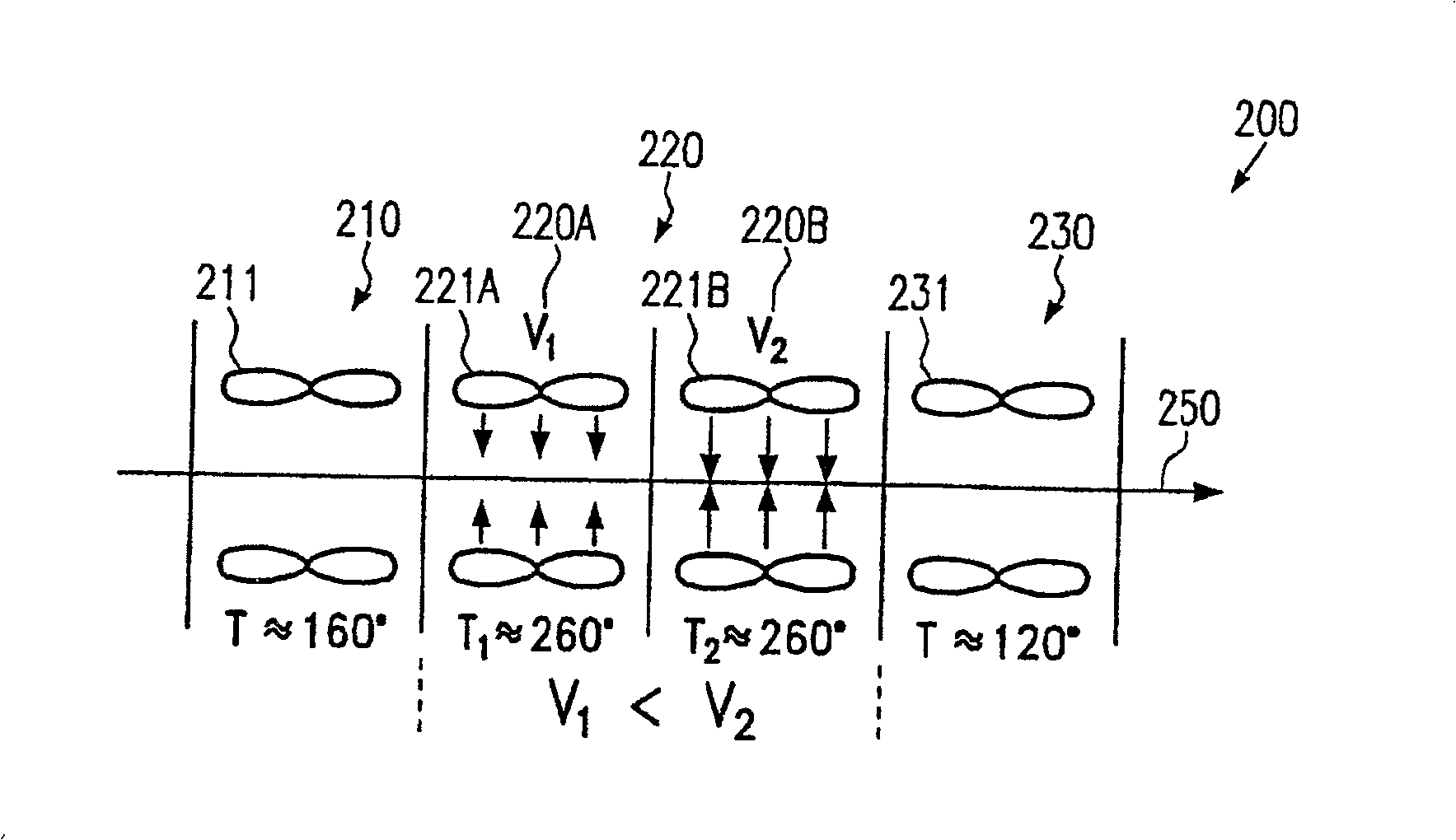

Method and device for reflow soldering with volume flow control

ActiveCN1902991AImprove energy efficiencyAvoid overall overheatingPrinted circuit assemblingSoldering apparatusHeat transmissionConvection heater

According to one aspect of the invention it is possible to rapidly heat a soldering item by reducing an initially larger volume flow at a constant or increasing temperature, effectively preventing small components from overheating. By using the volume flow of a convection heater to control effective heat transmission occurring on said soldering item, it is also possible to adapt the soldering process in an extremely flexible manner to special process requirements by virtue of the fact that adjustment of a modified volume flow can be controlled in a very quick and precise manner.

Owner:REHM THERMAL SYST

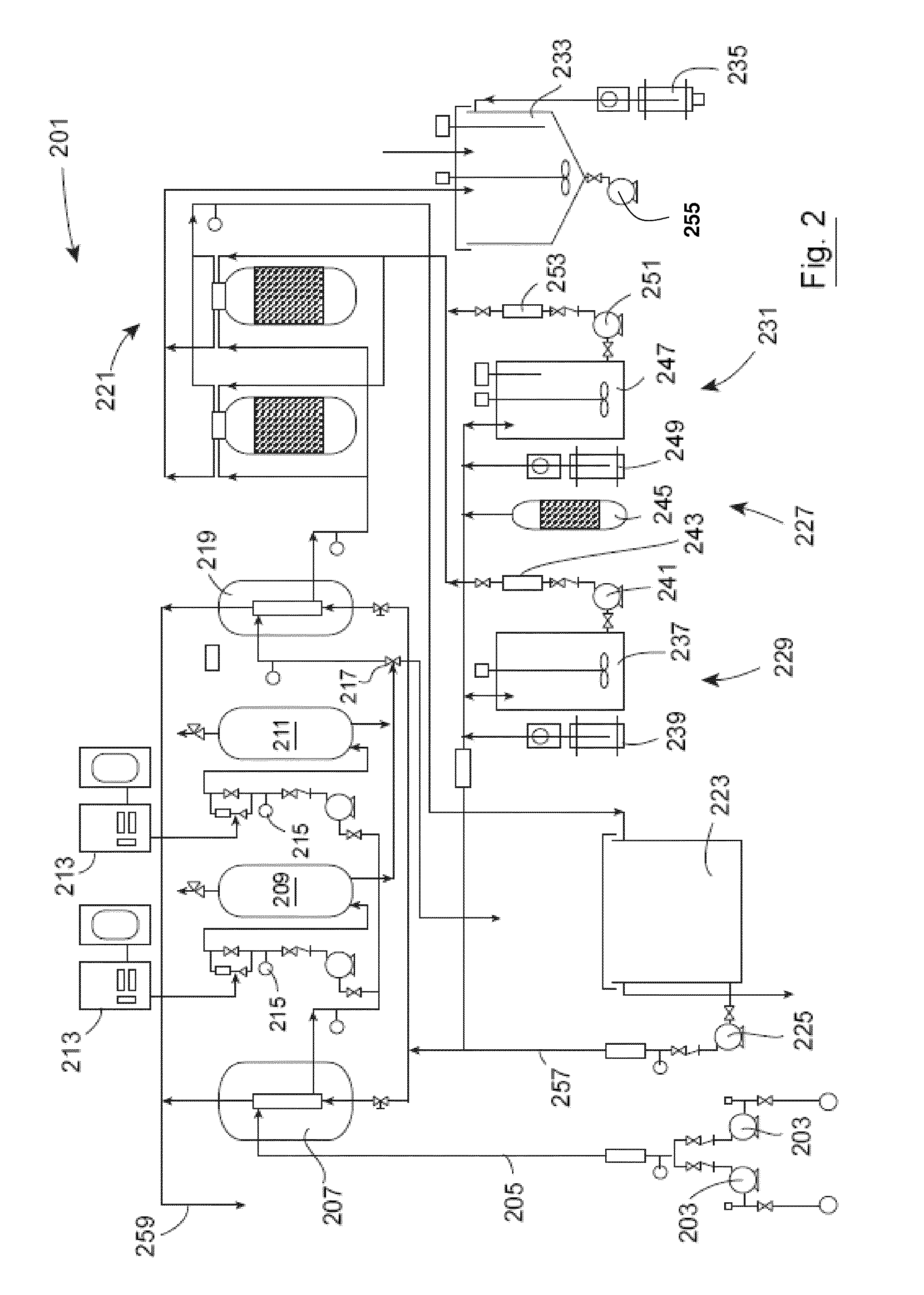

Effluent treatment process

InactiveUS20100032378A1OptimizationBeneficial usWater treatment parameter controlSpecific water treatment objectivesPhosphate levelIron oxide nanoparticles

According to the invention there is provided a tertiary effluent treatment process for reducing the phosphate levels in effluent. The process comprises the steps of delivering effluent from a wastewater treatment plant to a primary filter, delivering the filtered effluent to a series of two or more phosphate removal filters, delivering the filtered phosphate-depleted effluent to a treated water tank as treated water, delivering the filtered phosphate-depleted effluent from the treated water tank to a discharge tank as treated water; and, discharging the treated water from the discharge tank as required. Each phosphate removal filter comprises a plurality of polymer-based beads having nano-particles of iron oxide coated thereon. The advantage of using a series of two or more phosphate removal filters is that the process can deliver a final effluent containing specific pre-determined levels of phosphate that may be as low as 0.01 mg / L of effluent, but will in all cases be below 1 mg / L. The series of two or more filters also allow the process to accommodate variations in the phosphate content of the effluent without affecting the level of phosphate in the discharge, and, the system can be retro-fit to the end of any type of existing waste water treatment plant or can be integrated into a new facility.

Owner:OBRIEN PHILIP PATRICK PETER +1

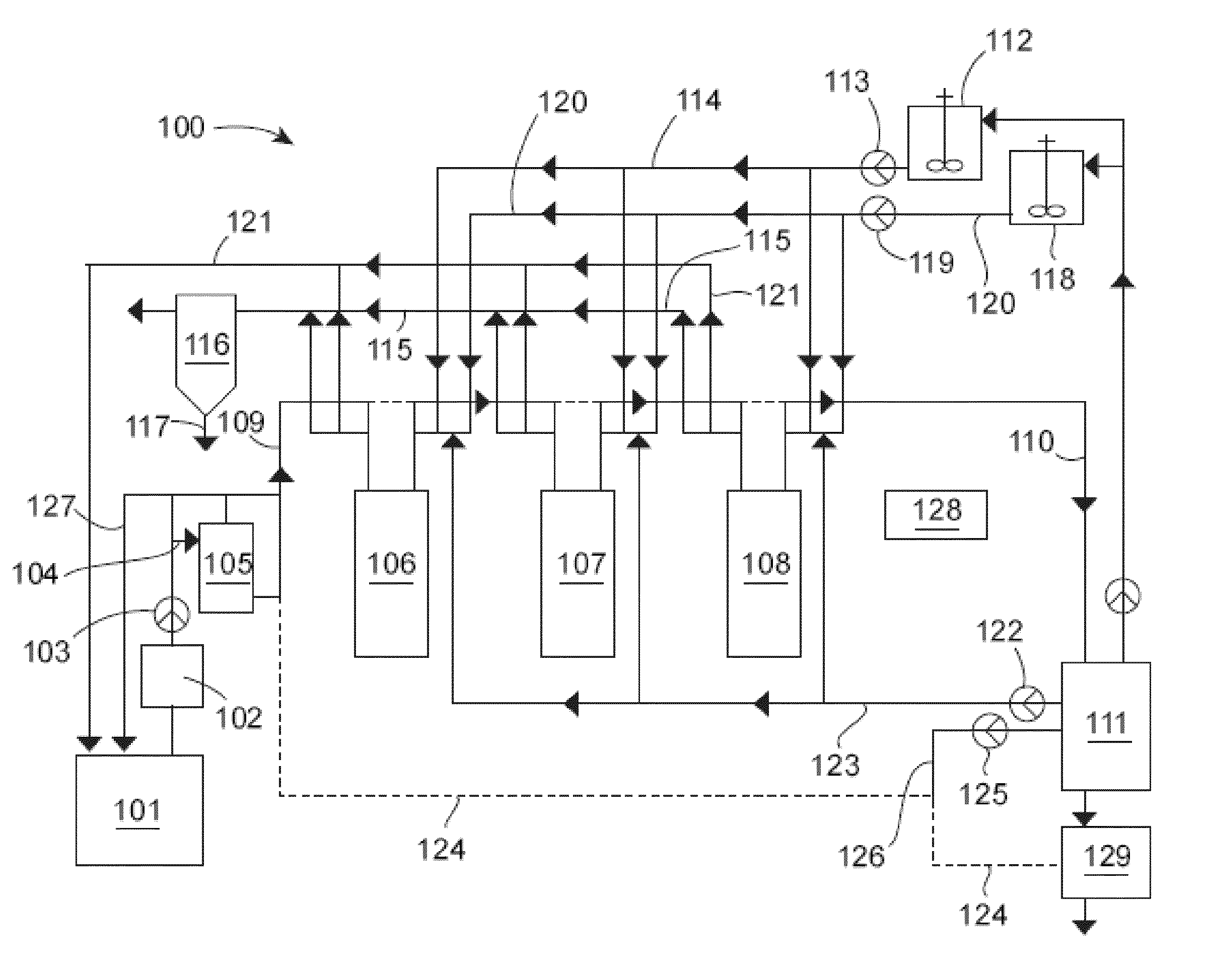

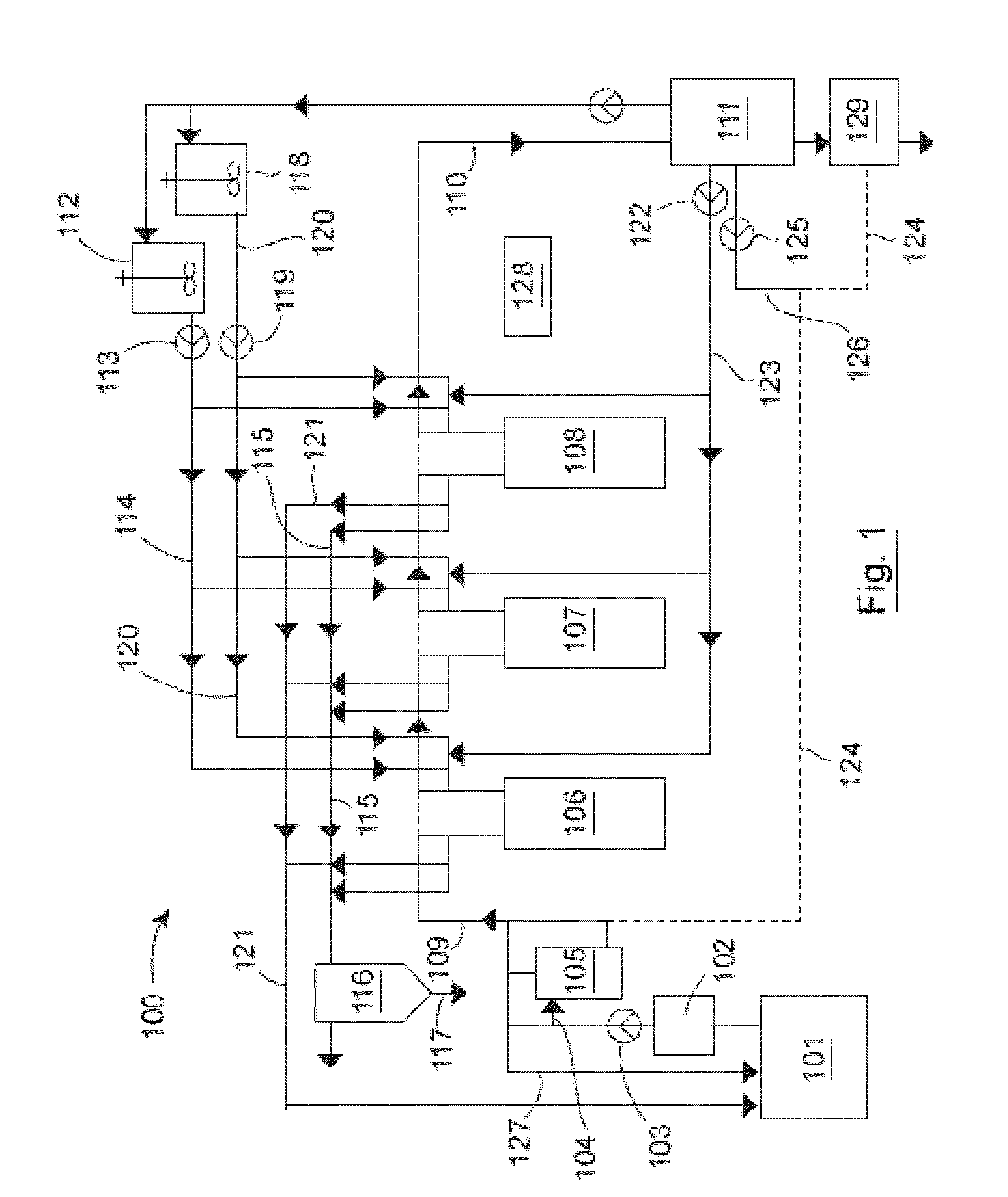

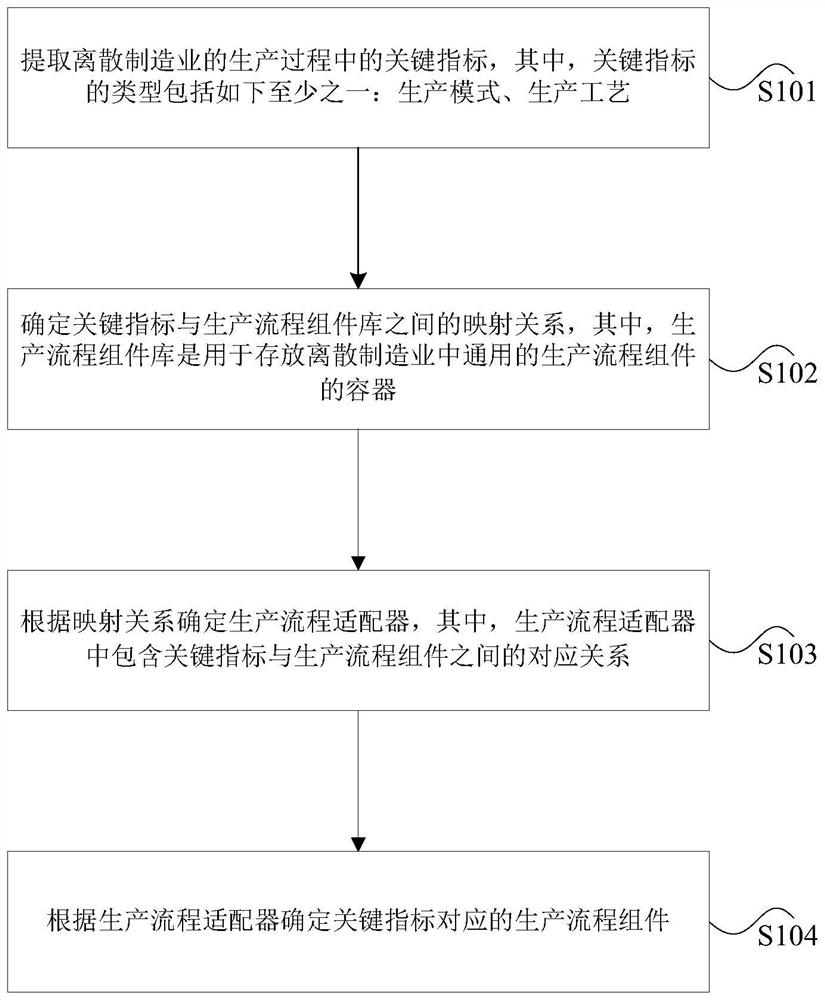

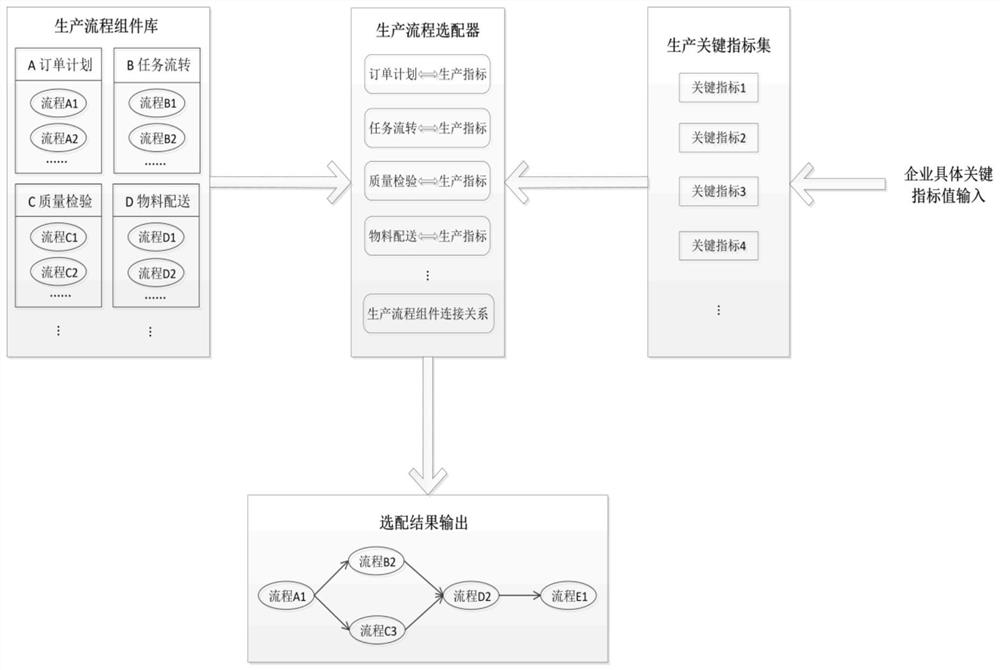

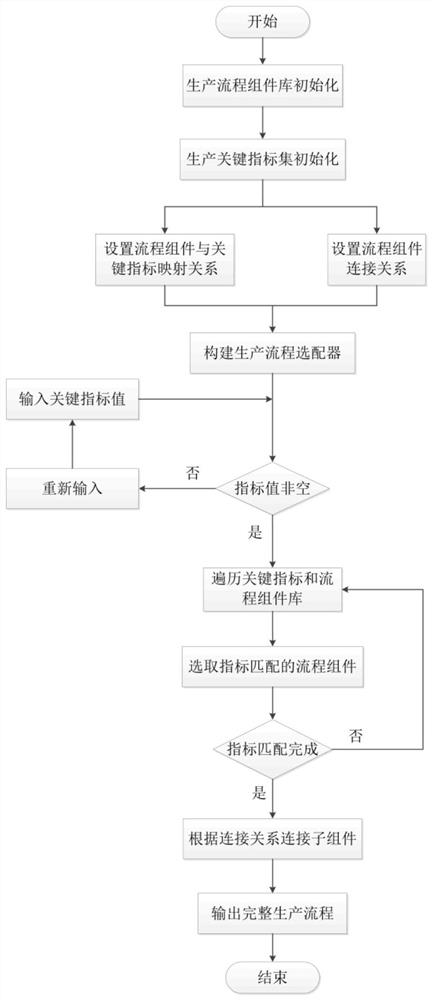

Manufacturing industry production process adaptation method and device, storage medium and processor

PendingCN114139945ASolve low production efficiencyImprove adaptabilityOffice automationResourcesProcess engineeringProcess adaptation

The invention discloses a manufacturing industry production process adaptation method and device, a storage medium and a processor. The method comprises the steps that key indexes in the production process of the discrete manufacturing industry are extracted, and the types of the key indexes comprise at least one of a production mode and a production process; determining a mapping relationship between the key indexes and a production process component library which is a container for storing universal production process components in the discrete manufacturing industry; a production process adapter is determined according to the mapping relation, and the production process adapter comprises the corresponding relation between the key indexes and the production process components; and determining a production flow component corresponding to the key index according to the production flow adapter. Through the method and the device, the problem of low production efficiency caused by low adaptability of the production process in the manufacturing industry in the related technology is solved.

Owner:CAXA TECH

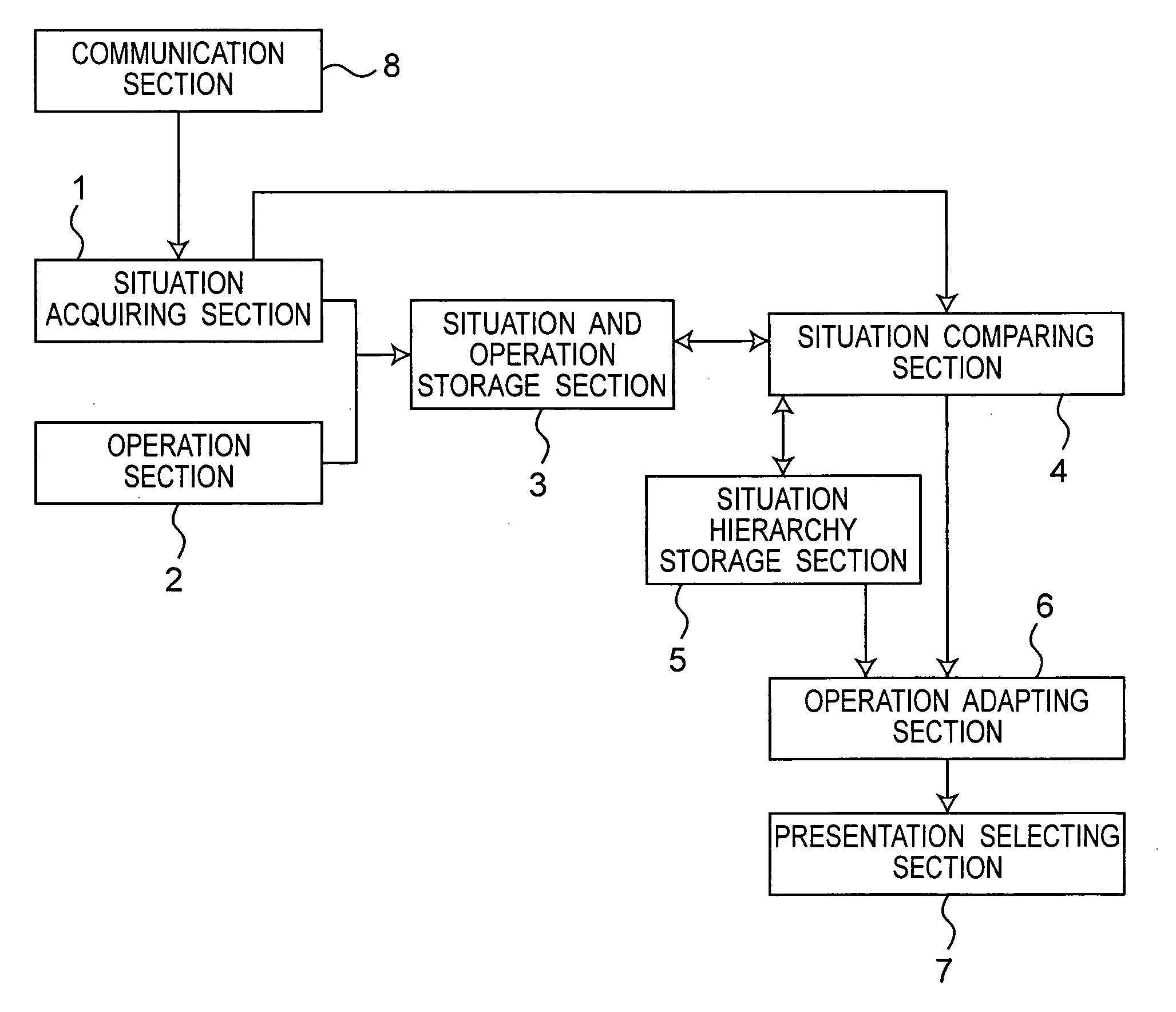

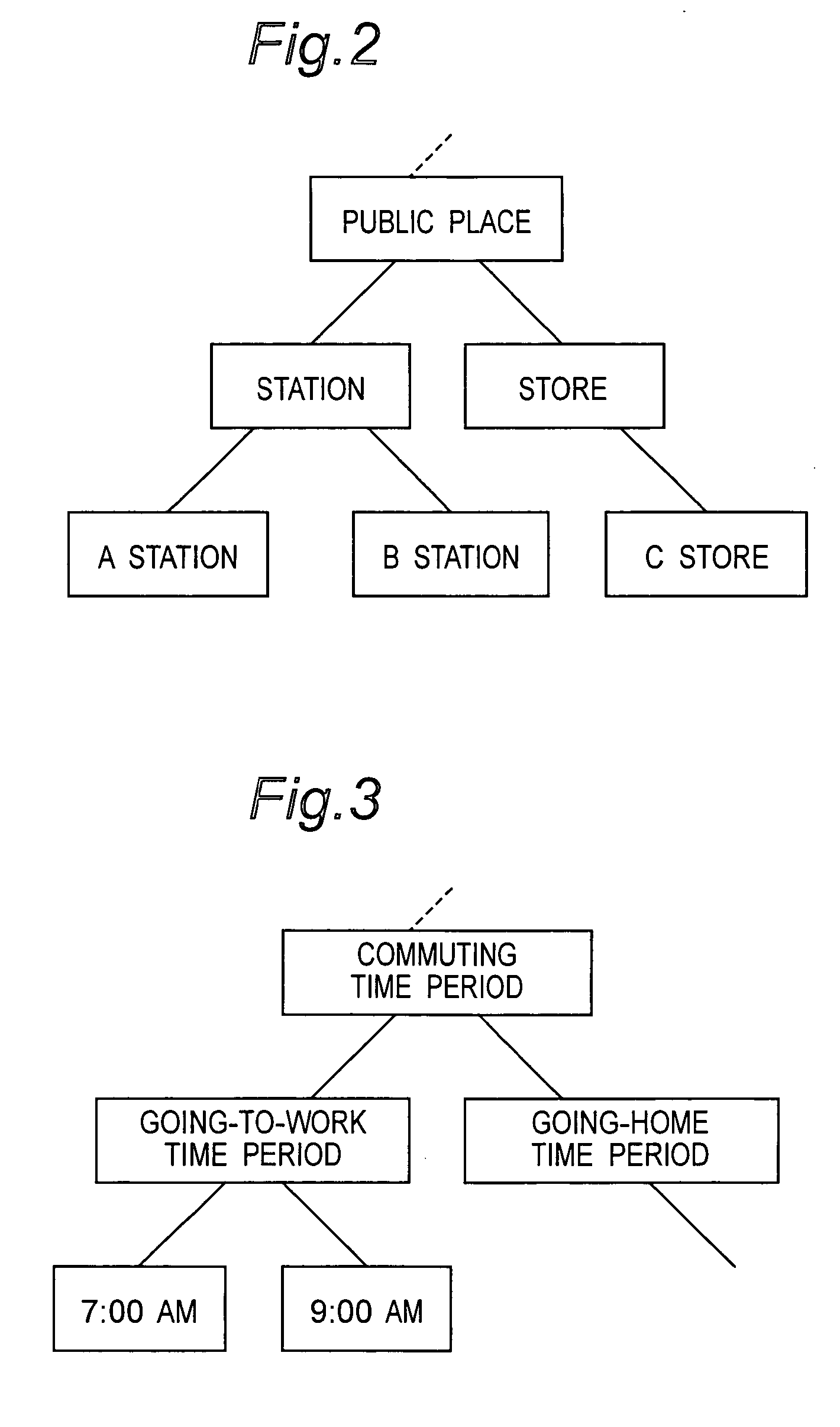

Information processor, mobile terminal, information processing system, information processing method, information processing program, and computer-readable recorded medium

InactiveUS20060095503A1Accurate predictionSimple procedureMultiple digital computer combinationsSubstation equipmentProcess adaptationInformation searching

In an information processor, a situation and operation storage section stores situation information, acquired by a situation acquiring section, about a situation in which an operation has been performed and operation information, received from an operation section, about the operation in an associated manner. A situation comparing section compares a current situation information piece with situation information pieces stored in the situation operation storage section. Based on situation information pieces stored in hierarchical structure in a situation hierarchy storage section, a broader concept common to two situation information pieces compared by the situation comparing section is searched for. If the broader concept of the current situation information piece agrees with that of a stored situation information piece, an operation adapting section adapts an operation procedure corresponding to stored operation information piece to the current situation, and a presentation selecting section executes the operation procedure.

Owner:SHARP KK

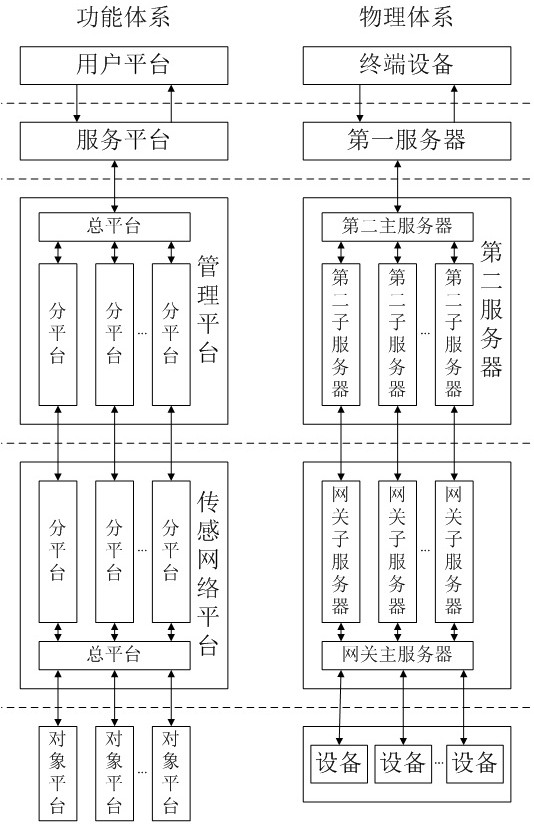

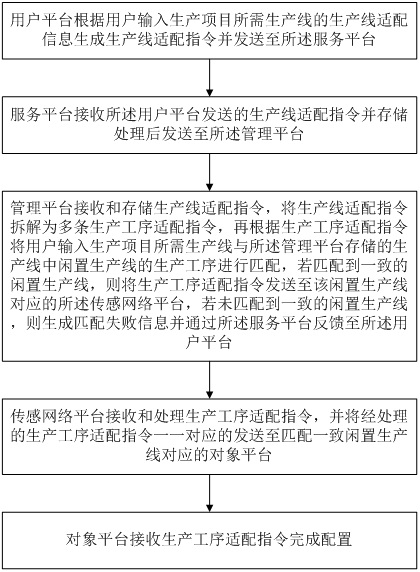

Production line adaptation method and system based on industrial internet of things

ActiveCN114815761ACost-effectiveFlexible controlResourcesTotal factory controlIndustrial InternetProcess adaptation

The invention discloses a production line adaptation method and system based on industrial Internet of Things, and the method is realized based on a user platform, a service platform, a management platform, a sensor network platform and an object platform which interact in sequence, and the user platform generates a production line adaptation instruction according to the production line adaptation information input by a user; the service platform receives the production line adaptation instruction and sends the instruction to the management platform; the management platform disassembles the production line adaptation instruction into a plurality of production process adaptation instructions, matches the production process of the required production line with the production process of the idle production line, sends the production process adaptation instructions to the sensing network platform if the production process of the required production line is matched with the production process of the idle production line, and generates matching failure information and feeds back the matching failure information to the user platform if the production process of the required production line is not matched with the production process of the idle production line; the sensing network platform sends the production process adaptation instruction to an object platform; and the object platform receives the production process adaptation instruction to complete configuration. According to the invention, the requirement of controlling different production projects at the same time can be met, intelligent manufacturing production line deployment can be carried out according to the production projects, and the cost performance of the system can be obviously improved.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

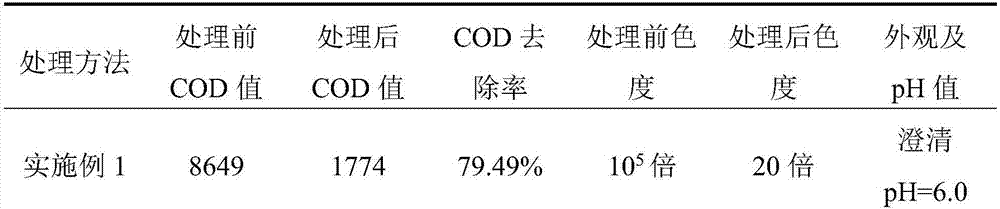

Method for online treating waterborne epoxy industrial paint circulating water in real time

InactiveCN107010703AReduce processing timeEconomical to handleWater/sewage treatment by flocculation/precipitationFlocculationEpoxy

The invention discloses a method for online treating waterborne epoxy industrial paint circulating water in real time. According to the method, coagulated substances and flocculates are directly dehydrated and removed after coagulation and flocculation steps by virtue of a method of compounding an inorganic high polymer coagulant and an organic high polymer flocculant, and therefore, production water can be circularly used, so that the water treatment time is shortened, the normal production is not influenced by a circulating water treatment process, the production work hour is guaranteed, the treatment process is rapid and efficient, the price advantage is obvious, and the water treatment economy is high. By collecting circulating water from paint fog and timely utilizing circulating water in a production period of waterborne epoxy industrial paint, most waterborne resin, pigments, fillings and the like in the circulating water can be removed, so that a circulating use purpose is achieved, the online, real-time and dynamic management of coating wastewater of waterborne paint is realized, and the production process of an enterprise can adapt to the change of the industrial paint from an oil property to a water property.

Owner:GUANGDONG UNIV OF TECH

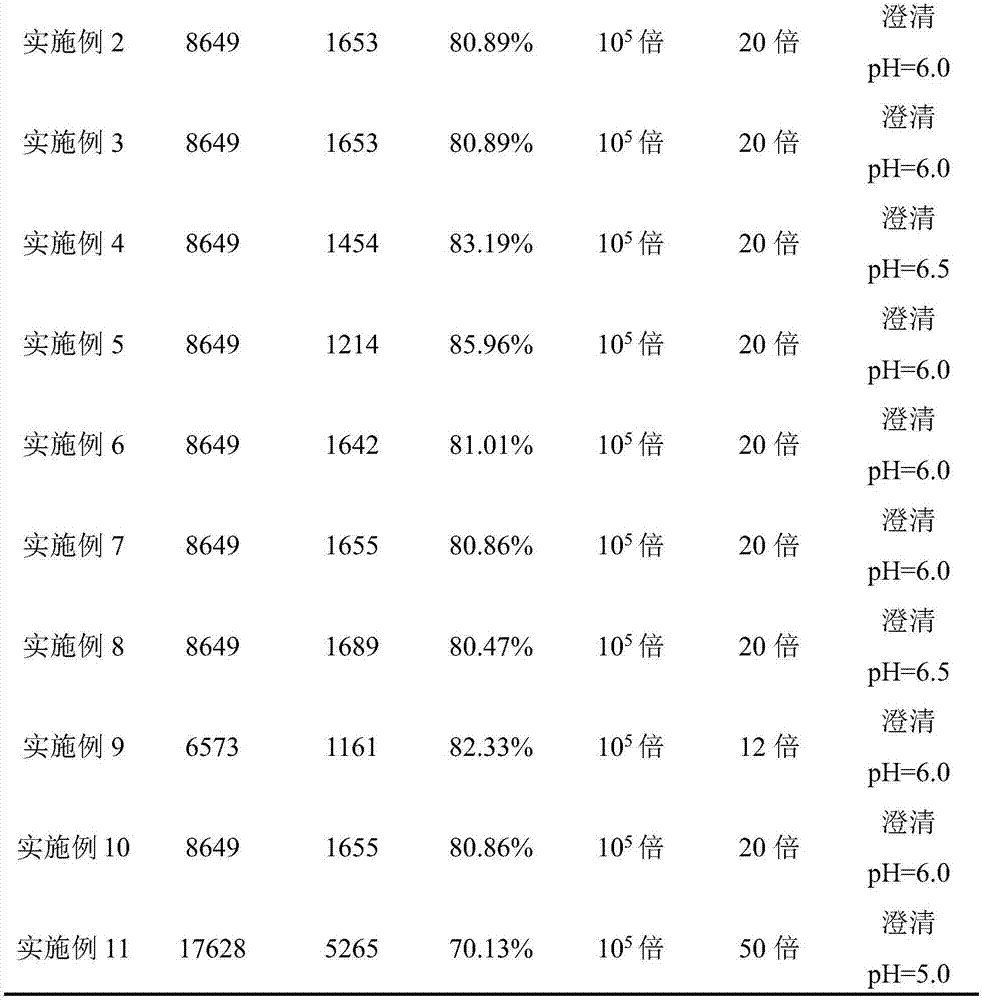

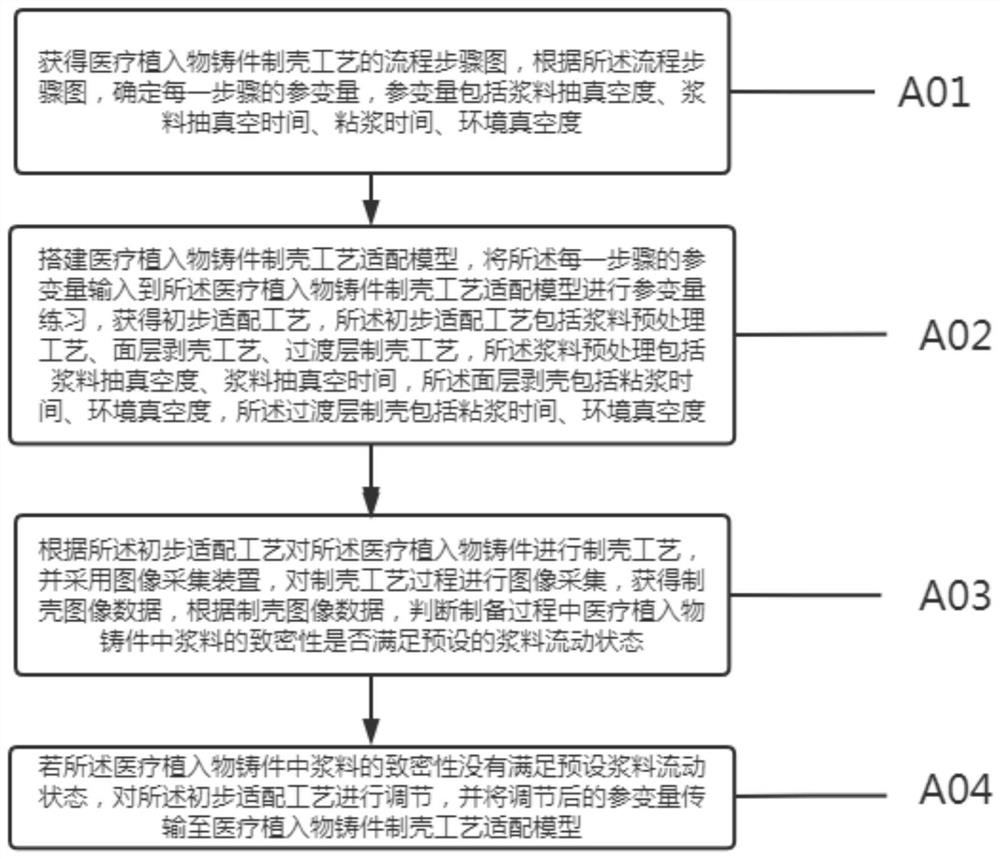

Medical implant casting shell making process supervision and detection method based on block chain

PendingCN114309468AReduce scrap rateReduce generationImage analysisFoundry mouldsMedicineProcess engineering

The invention discloses a medical implant casting shell making process supervision and detection method based on a block chain, and the method comprises the steps: A01, determining the parameter of each step according to a flow step graph; a02, a medical implant casting shell making process adaptive model is built, and a preliminary adaptive process is obtained; a03, carrying out image acquisition on the shell making process to obtain shell making image data, and judging whether the compactness of the slurry in the medical implant casting meets a preset slurry flowing state or not according to the shell making image data; and A04, if the compactness of the slurry in the medical implant casting does not meet the preset slurry flowing state, the preliminary adaptation process is adjusted, and the adjusted parameter is transmitted to the medical implant casting shell making process adaptation model. According to the technical scheme, key steps in the medical implant casting shell making process are supervised, the compactness of slurry in a medical implant casting is analyzed, the rejection rate of the casting is reduced, and data in the technological process are processed through the block chain technology, so that effective management is achieved.

Owner:刘二松

Dry vacuum pump pumping process simulation test method and test system

ActiveCN104632604BExtraction process optimizationGuaranteed zero emissionsPump testingPump componentsEnvironmental resistanceEtching

Disclosed are a vacuum pump air exhaust process simulating and testing method and a testing system. By means of a built simulating vacuum chamber, common elements in various dry-type vacuum pump application environments such as gas, liquid, electricity, magnetism, heat, dust, and corrosion are integrated, various sensors are used to perform feedback on a signal simultaneously having temperature, humidity, gas ingredient, real-time image, pressure, traffic and noise, and multiple control systems are used to perform monitoring, so as to check and improve dry-type vacuum pump air exhaust process adaptation situations. The testing system uses strict contaminant collecting and shuttling treatment, has a danger warning and automatic protecting function system, is characterized by being secure, intelligent, and green and environment-friendly, has good repeatability, and may simulate vacuum pump air exhaust process environments such as cleaning, mildly-polluted, intermediately-polluted and seriously-polluted vacuum environments comprising transfer, physical vapor deposition, chemical vapor deposition, etching, photolithography, chemical engineering, and pharmacy.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

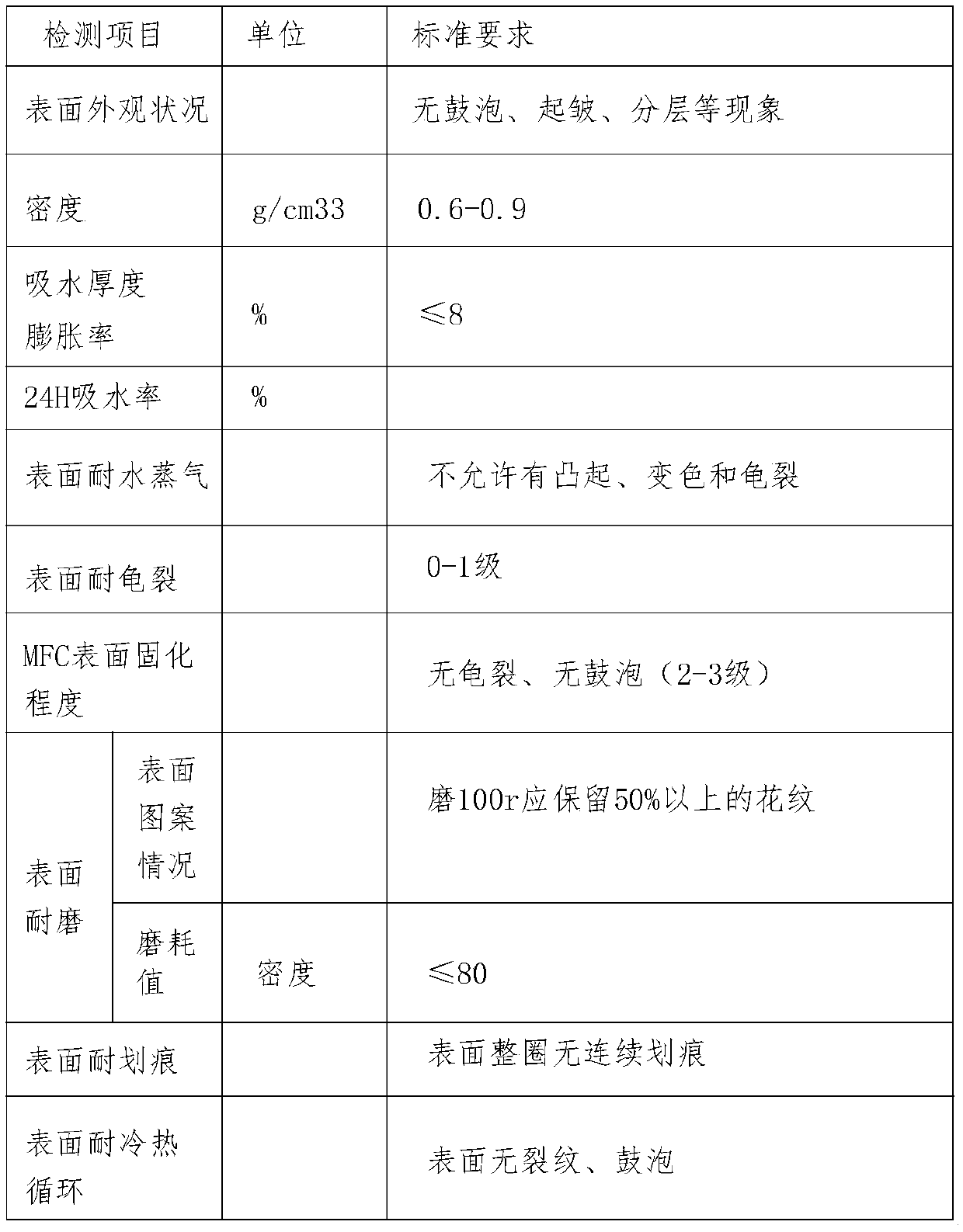

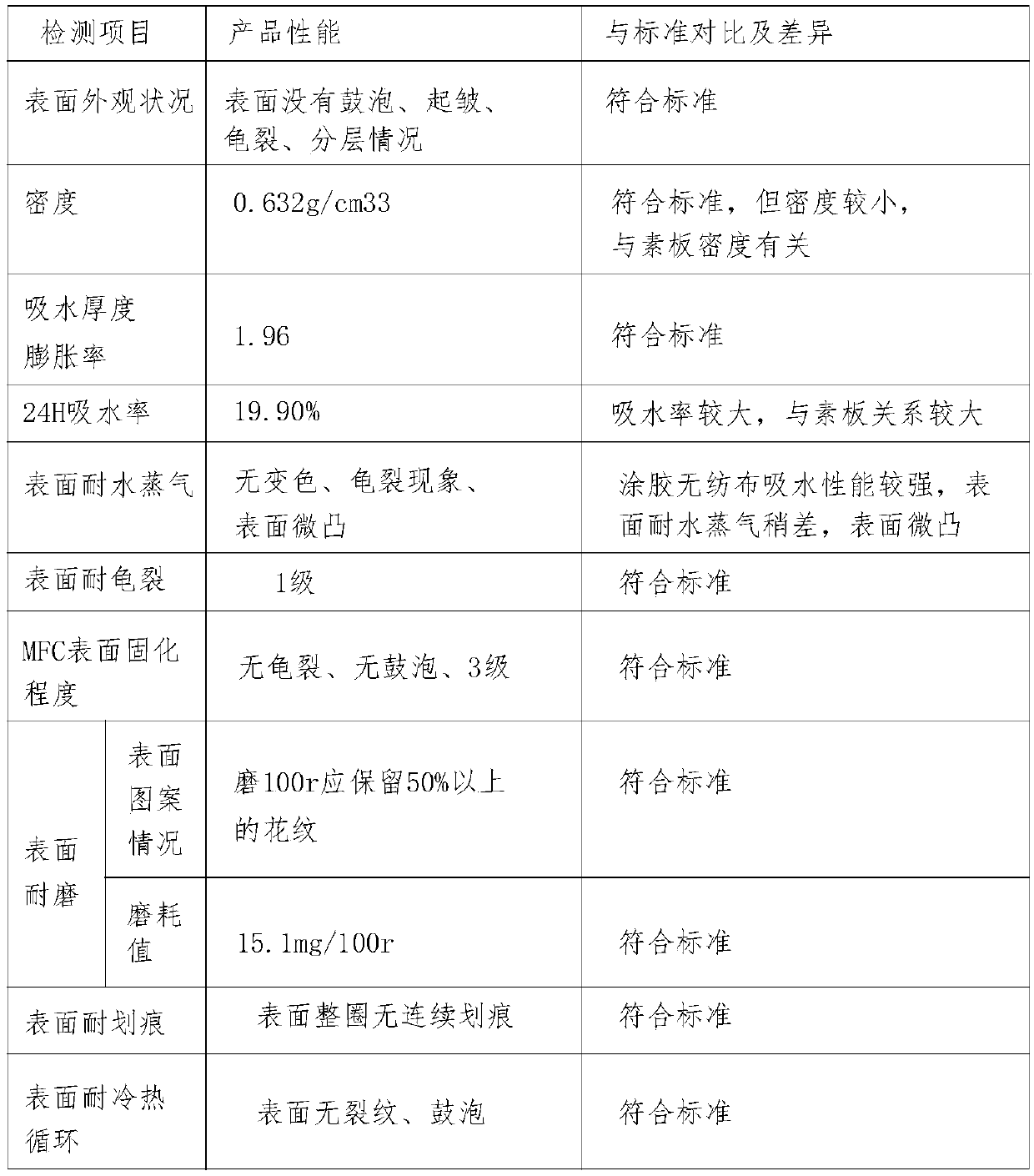

Technical wood veneer composite hot pressing process

InactiveCN109623973AImprove crack resistanceGood anti-cracking effectWood veneer joiningAdhesive application devicesWood veneerEnvironmental resistance

The invention relates to the technical field of technical wood, and discloses a technical wood veneer composite hot pressing process. The purposes that technical wood veneer can be prevented from fracturing at the area where the temperature difference is relatively large, and volume production can be carried out through different hot presses are achieved. By means of the process, hot pressing is carried out on the technical wood veneer, due to the fact that the tenacity of fusing of urine glue and flour is relatively large, especially at the northeast and at the foreign area where the freezingtemperature difference is relatively large, the technical wood pressed through the process has a good fracturing prevention effect, balance paper below dipping film adhesive is omitted, the content of formaldehyde in melamine paper of a finished plate product is reduced, a higher environmental friendliness requirement is met, meanwhile, the stability and moderation of the cost are kept, moreover,volume production can be carried out through the different hot press by means of the process, and then the production efficiency and the process adaptation are greatly improved.

Owner:FOSHAN CITY YATE OFFICE FURNITURE CO LTD

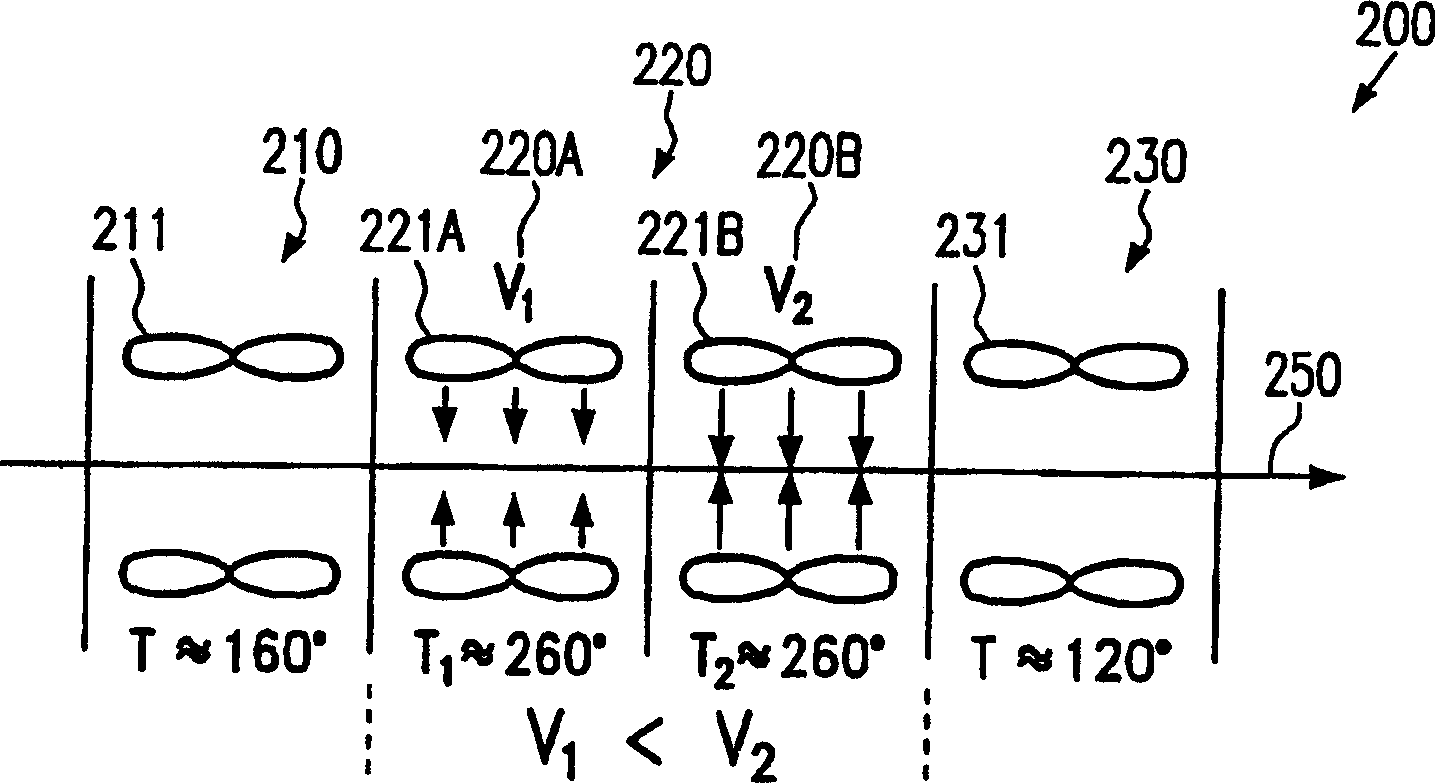

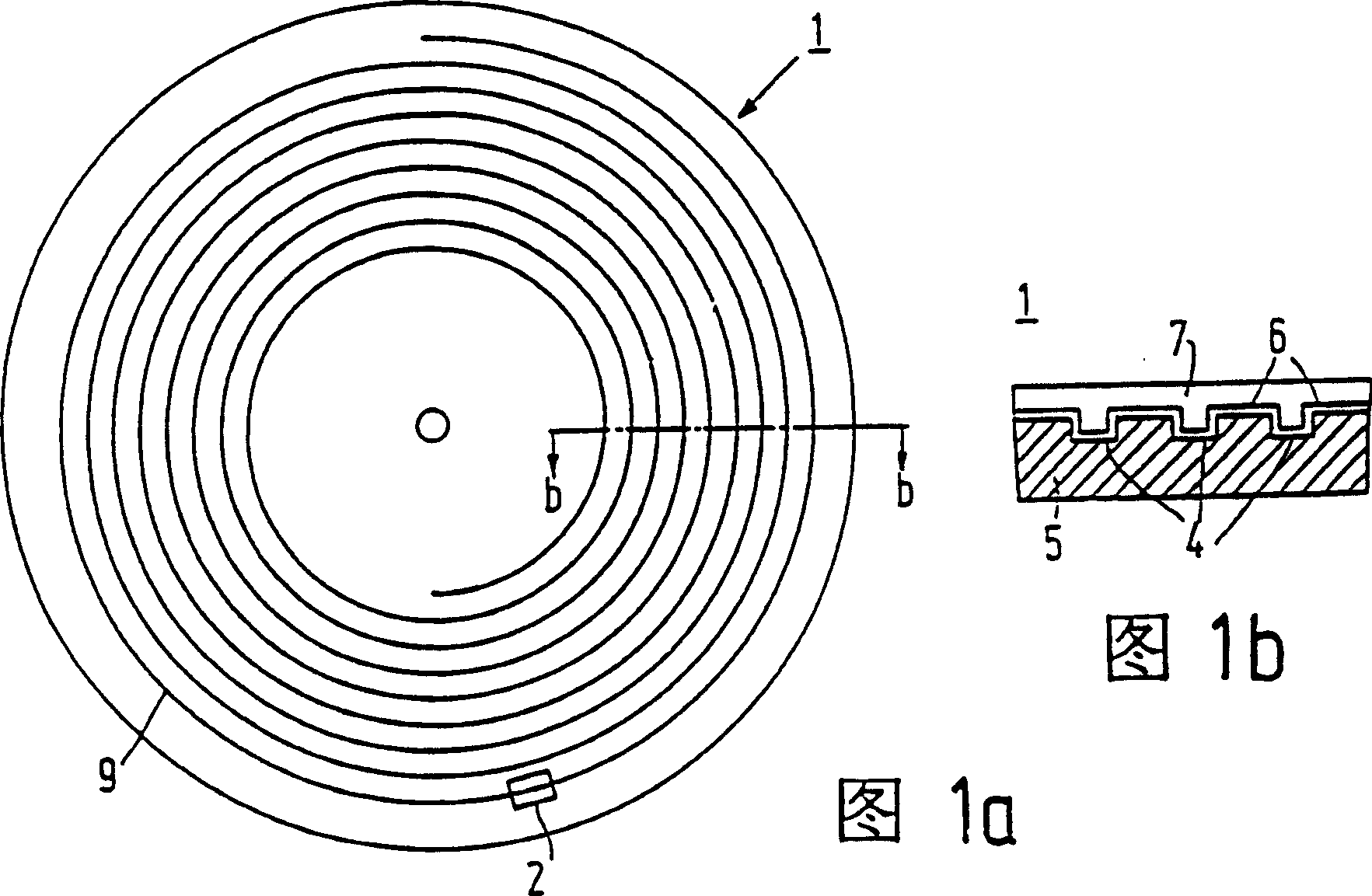

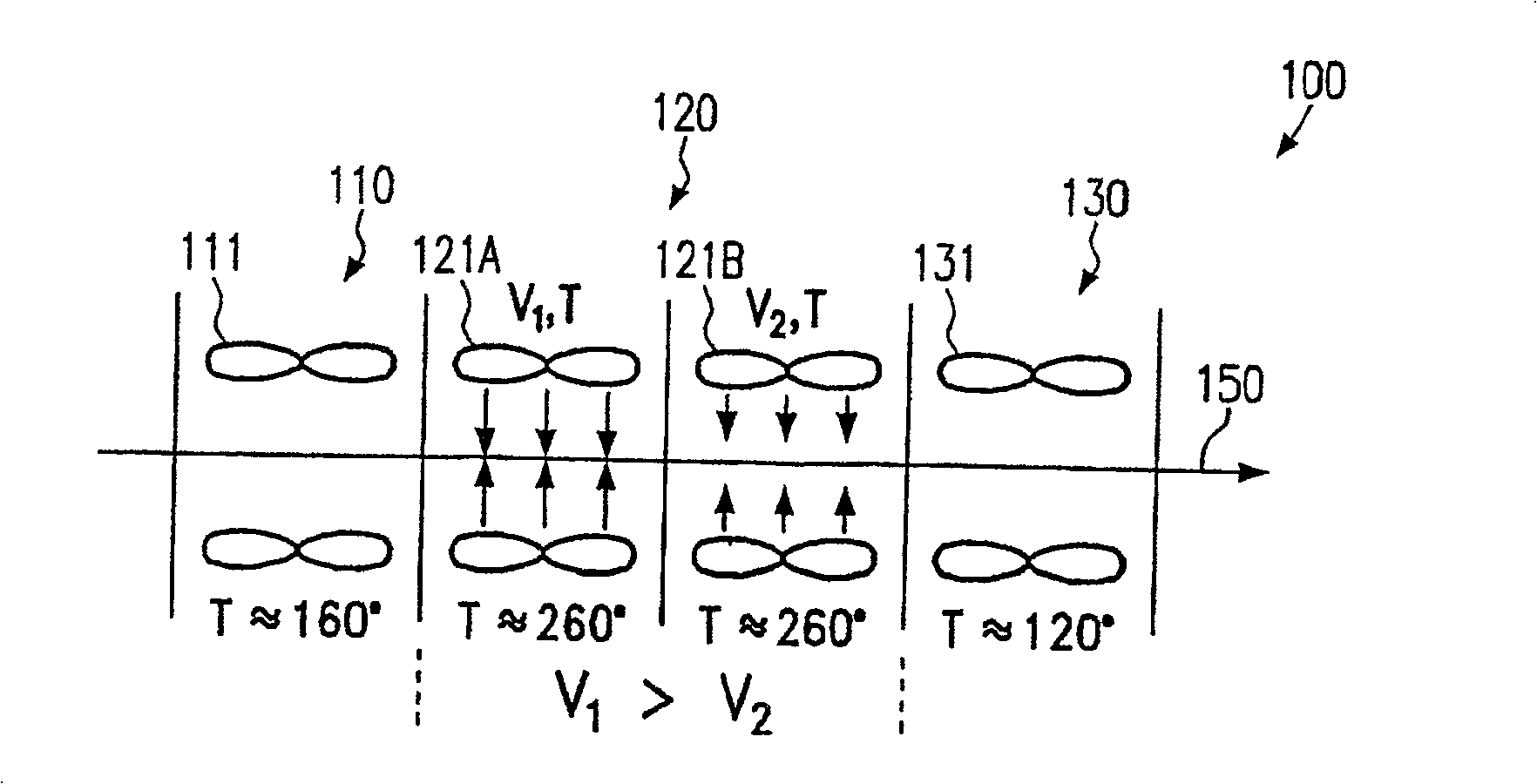

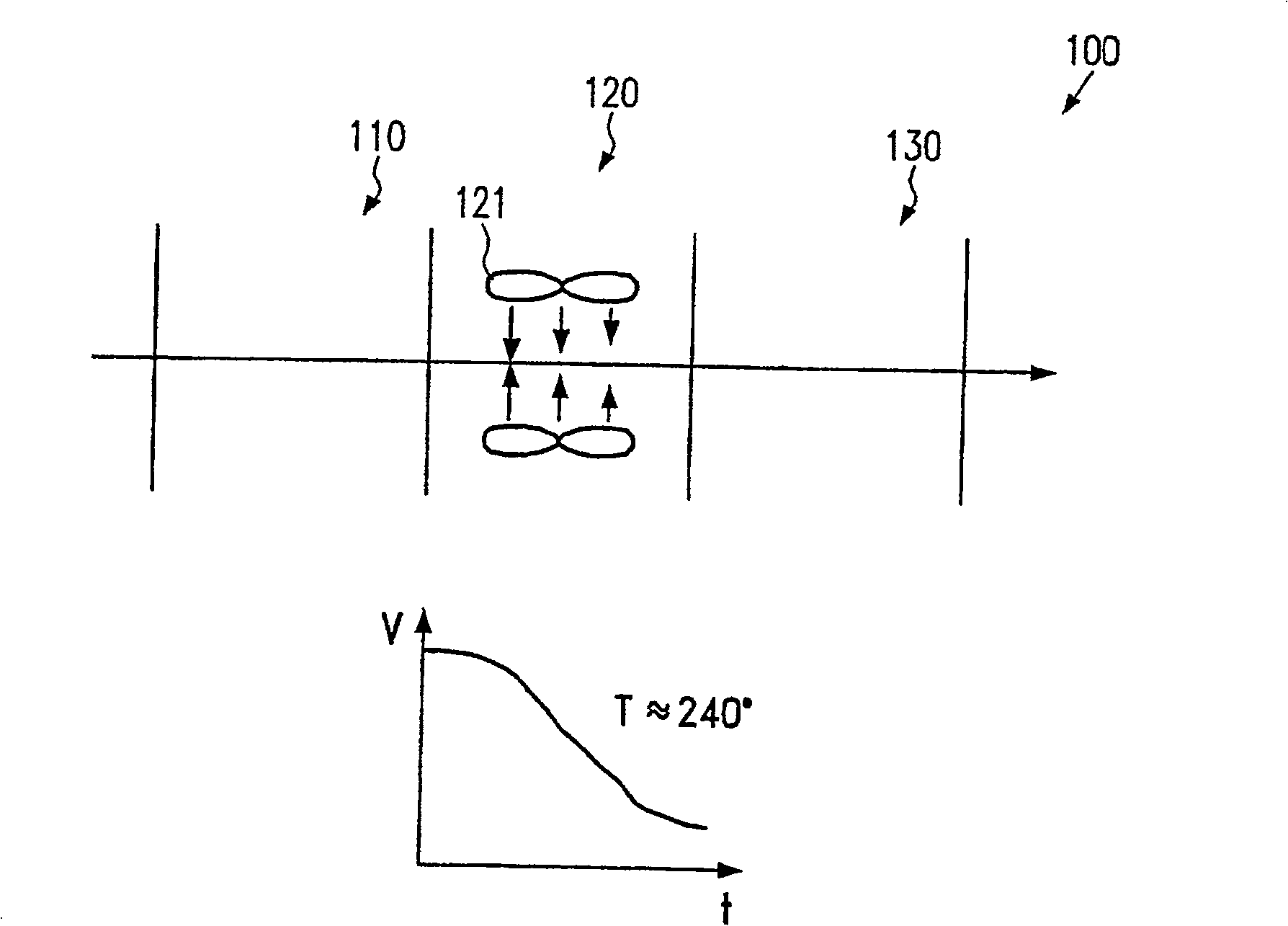

Information carrier and recording equipment used for recording information carrier

InactiveCN1475991AModification of read/write signalsInformation arrangementProcess adaptationComputer science

The information carrier according to the invention is of an optically inscribable type, such as a CD-E or CD-WO. Information can be recorded as a track of patterns on the information carrier. The manufacturer has provided the information carrier with carrier information, for example, information about the write power to be used. It is desirable for the patterns to have constant dimensions, irrespective of the velocity at which they are recorded. The recording process in which the recording is effected is therefore to be adapted to the recording velocity. In order to attune this adaptation to the information carrier, the latter contains velocity-related information indicative of the recording process related to a recording velocity, for example, a reference velocity (V1-V3), while the remaining recording parameters (W1-W3) are given for a minimum and / or maximum recording velocity at which the information carrier can be recorded. The device reads the velocity-related information from the information carrier and adapts the recording process to the recording velocity that must actually be used.

Owner:KONINKLJIJKE PHILIPS NV

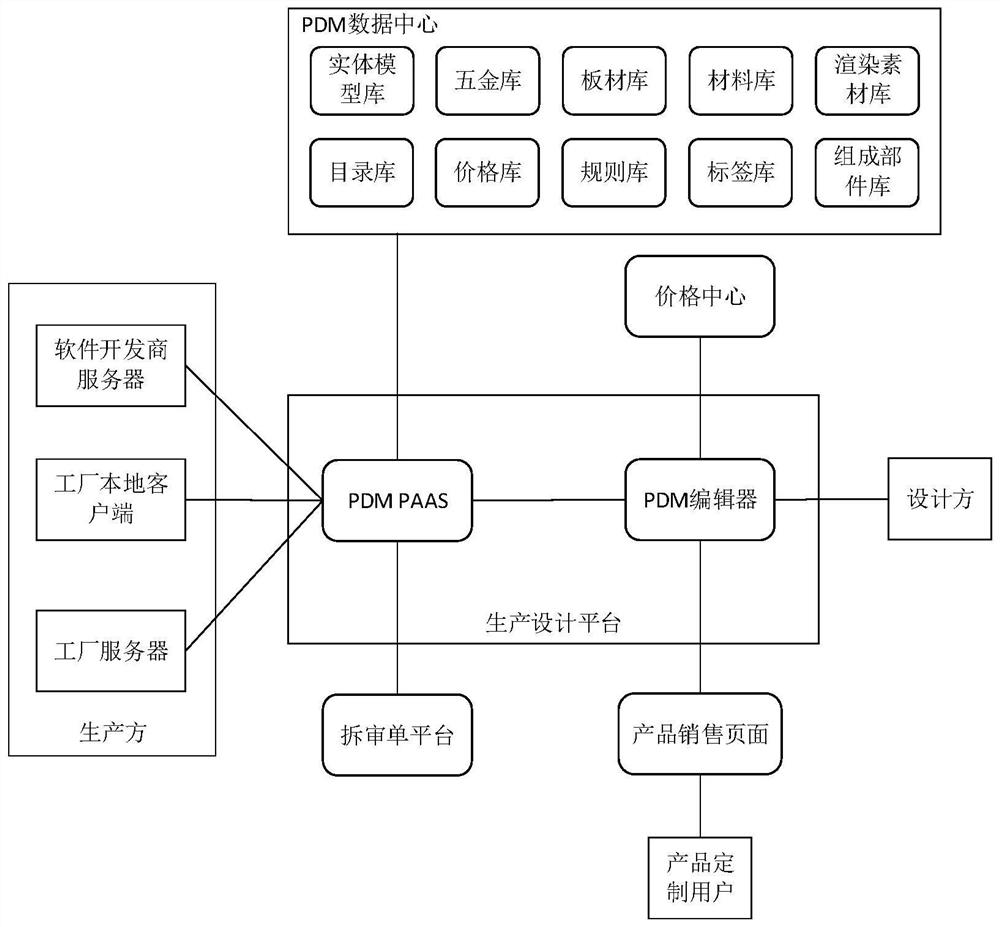

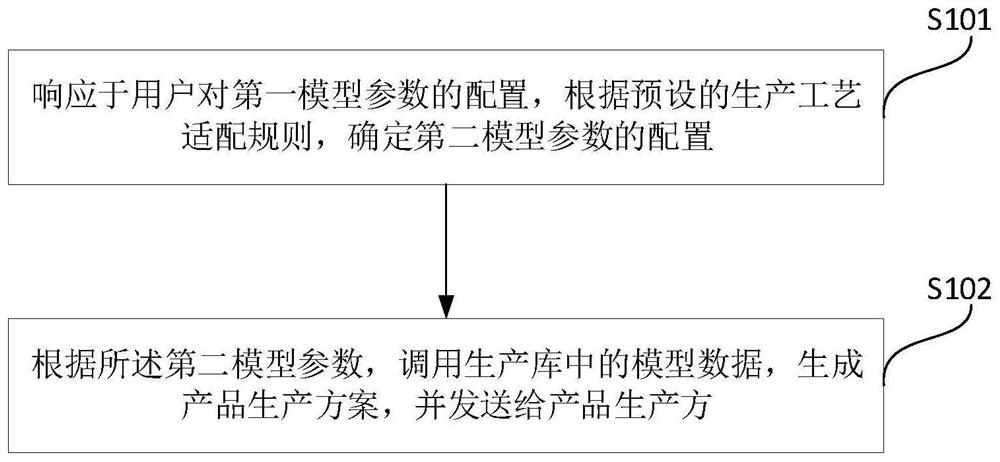

Product customization data processing method and device and electronic equipment

PendingCN113421139AMeet design needsMatch process adaptation requirementsBuying/selling/leasing transactionsSoftware engineeringProcess adaptation

The embodiment of the invention provides a product customization data processing method and device and electronic equipment, and the method comprises the steps: responding to the configuration of a user for a first model parameter, determining the configuration of a second model parameter according to a production technology adaptation rule, the first model parameter being a model parameter oriented to a customization user, the second model parameter being a model parameter oriented to a producer; and according to the second model parameter, calling model data in a production library, generating a product production scheme, and sending the product production scheme to a product producer. According to the embodiment of the invention, the model parameters which can be conveniently configured by the customized user are abstracted from the model parameters oriented to the producer, and then the model parameters oriented to the producer are generated based on the model parameters configured by the customized user through calculation of the background process adaptation rule. Through the mechanism, the product design requirement of the customized user is met, the process adaptation requirement of the producer is also met, and the link between the customized user and the producer is opened.

Owner:ALIBABA GRP HLDG LTD

Method and device for reflow soldering with volume flow control

InactiveCN100536638CAvoid overall overheatingImprove heat transfer efficiencyPrinted circuit assemblingSoldering apparatusConvection heaterProcess adaptation

According to one aspect of the invention, it is possible to effectively prevent overheating of small parts by rapidly heating the objects to be brazed by reducing the initially large volume flow at a constant or elevated temperature. By utilizing the volume flow of the convection heater to control the effective heat transfer that takes place on the objects to be brazed, it is also possible to adapt the brazing process extremely flexibly to specific process requirements due to the regulation of the changed volume flow can be controlled very quickly and precisely.

Owner:REHM THERMAL SYST

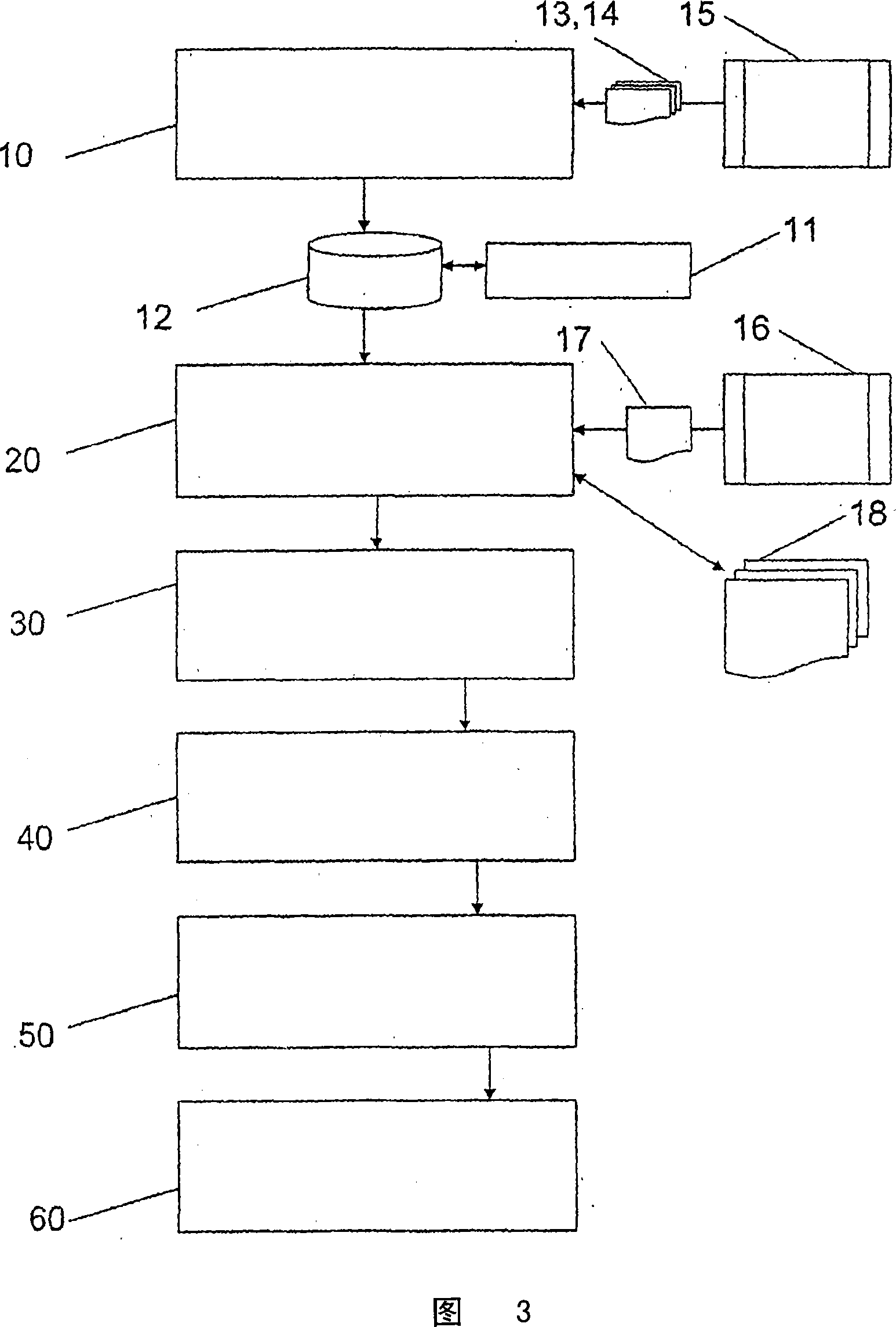

Method and system for correcting programming and optimising treatment processes

ActiveCN101133428BReduce in quantityImprove efficiencyForecastingResourcesProcess adaptationProduction planning

The invention relates to a method and a system for corrective planning and optimization of processing and / or continuation of processing in technical production enterprises, in particular in the paper industry, wherein the system has a function for starting from a predetermined production plan by means of Means for processing characteristic parameters (13) and quality information (14) of at least one output product of a preceding production stage to carry out an optimization adapted to said further processing.

Owner:ABB PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com