Dry vacuum pump pumping process simulation test method and test system

A dry vacuum pump and process simulation technology, applied in pump testing, pump, pump control, etc., to achieve intelligent green environmental protection, good application prospects, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

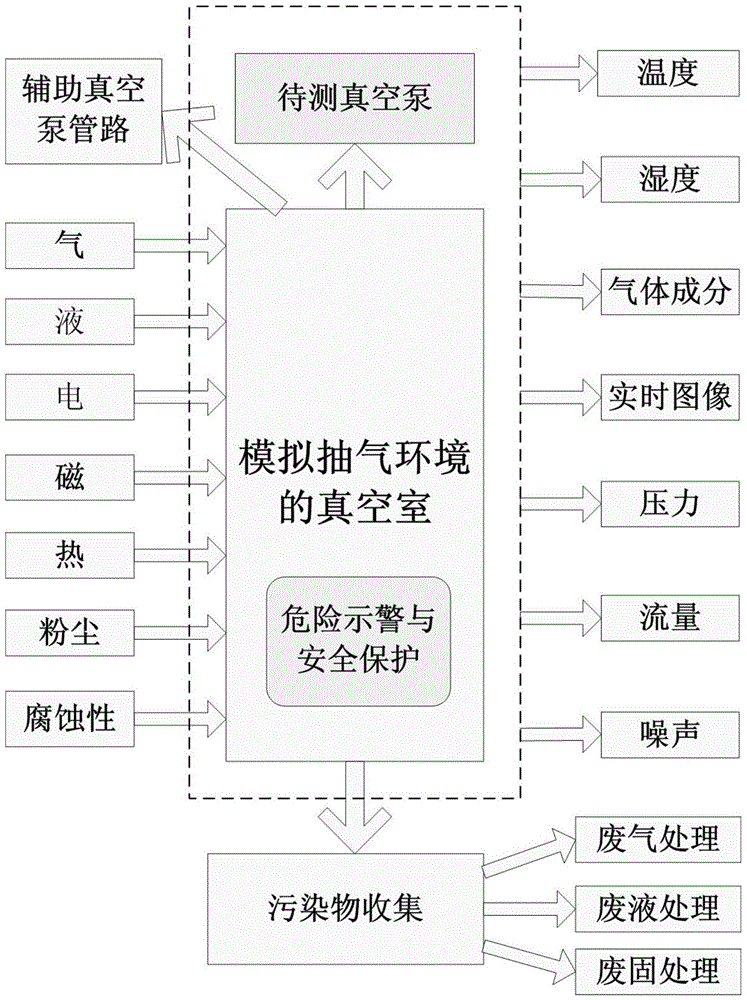

Method used

Image

Examples

Embodiment 1

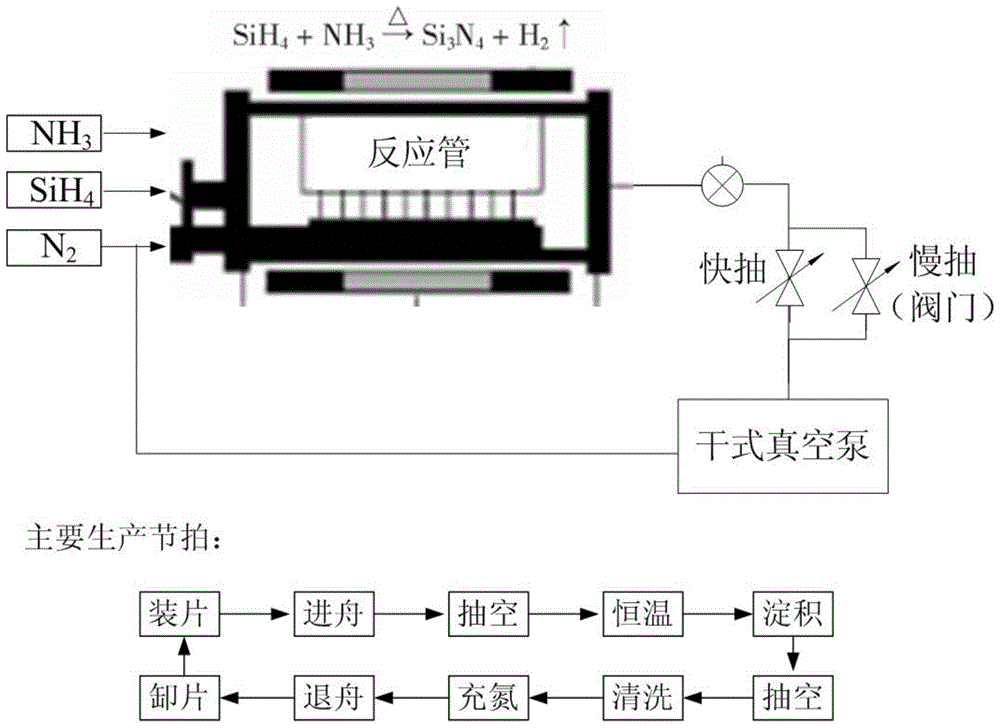

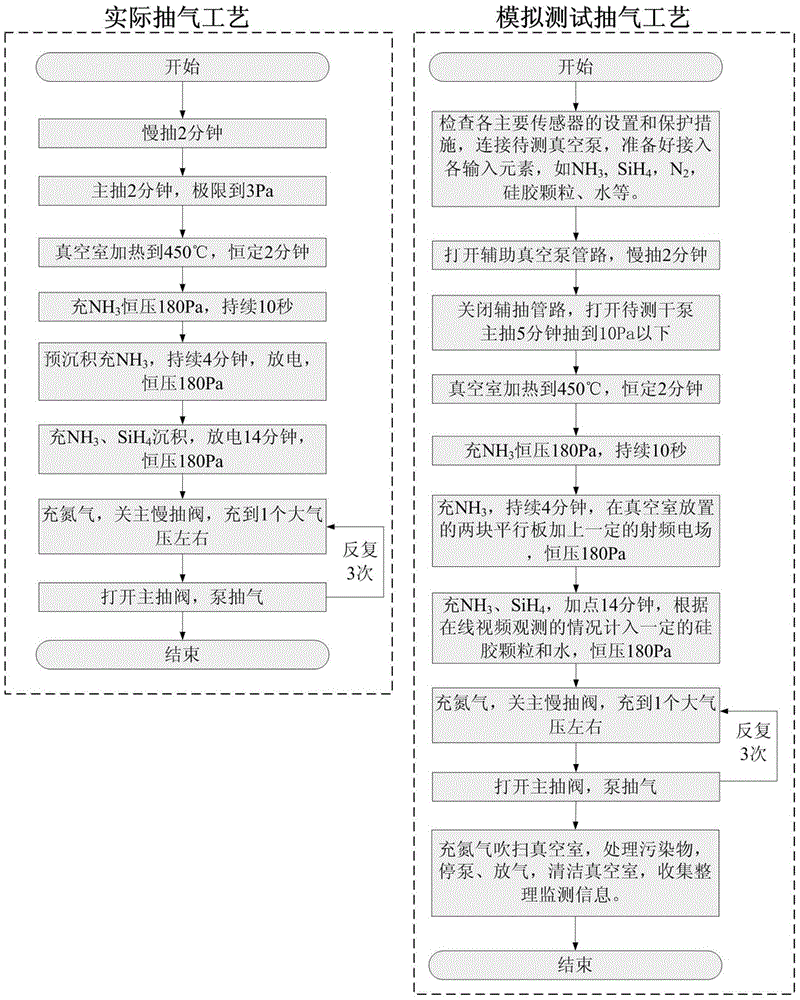

[0059] Embodiment 1 Tubular PECVD pumping process simulation test

[0060] Embodiment 1 provides a dry vacuum pump pumping process simulation test method equipped with tubular PECVD equipment, and the dry vacuum pump pumping process simulation test system disclosed in the present invention is used for testing.

[0061] PECVD is one of the typical production processes in the IC industry. Its dry pump consumption is large and the pumping environment is harsh. There is an urgent need for dry pumps to adapt to the harsh pumping process. The pumping process of the PECVD tube furnace is complex, and the gas and by-products of the process include substances that are spontaneously combustible, flammable, corrosive, condensable and toxic. The dry pump working under this process must have high reliability and corrosion resistance. Usually, absolute safety is required in the pumping process, and these gases usually have a relatively high temperature, and excessive cooling is not allowed...

Embodiment 2

[0064] Example 2 MOCVD pumping process simulation test

[0065] Another typical harsh process is the MOCVD pumping process. Since MOCVD works in a relatively high-pressure vacuum, it contains metal debris and smoke, and it is explosive due to the hydrogen gas. The simulation of the MOCVD pumping process is roughly equivalent to that of PECVD, but on the input elements, a certain amount of metal microbeads and ceramic microbeads should be added, and H2 gas should be filled.

Embodiment 3

[0066] Embodiment 3 RH / VOD extraction process simulation test

[0067] RH / VOD is a typical vacuum metallurgical process for vacuum degassing treatment of molten steel. Traditionally, a steam jet pump is used as the air extraction system. However, due to the low extraction efficiency of the water vapor jet pump and the large footprint , Huge power consumption and water consumption, time-consuming and labor-intensive maintenance, there are already examples of using dry vacuum pumps (units) to replace them. The extraction process of RH / VOD is also relatively harsh, usually containing a variety of by-products such as various gases, high-temperature water vapor, metal debris, slag, and dust.

[0068] For the simulation test of the RH / VOD pumping process, the basic method is similar to that of PECVD, but the proportion of water and metal microbeads in the input elements is increased, and a certain amount of dust should be added at the same time. During the simulation, fine sand part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com