Method for online treating waterborne epoxy industrial paint circulating water in real time

A water-based epoxy, real-time treatment technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of poor water-based paint wastewater treatment effect, poor process economy, and poor application effect and other problems, to achieve the effects of good water treatment economy, improved separation efficiency, and fast settling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

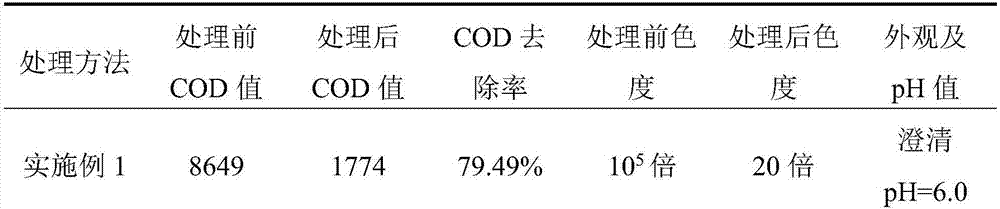

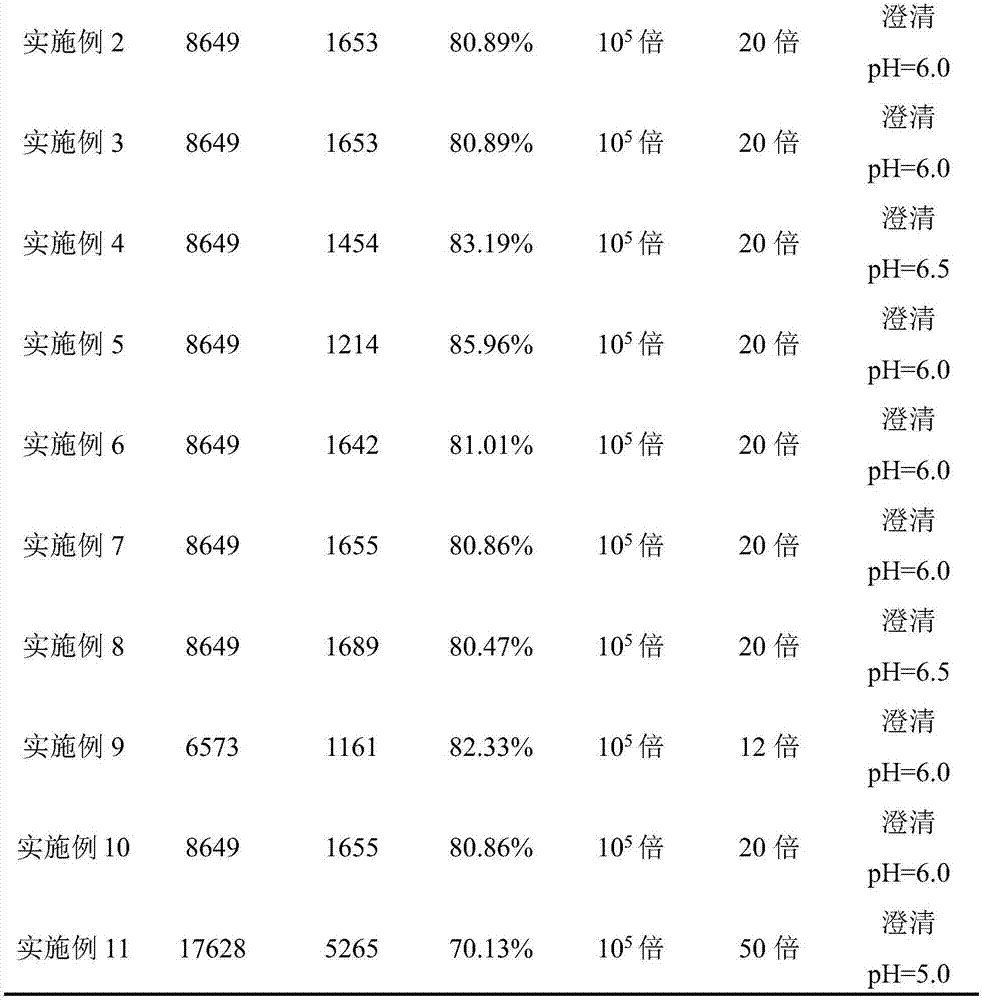

Embodiment 1

[0024] The paint spraying room uses circulating water to collect paint mist. After a certain number of shifts, the concentration of water-based paint in the circulating water reaches above 10% (mass fraction), the circulating water looks turbid, and the COD reaches above 8,500. Add 3.4% (mass fraction) coagulant PFS into the circulating water of water-based epoxy paint, first stir at 250r / min for 1min, then stir at 50r / min for 5min, then let the circulating water stand for 15min, then add Flocculant PAM, stir at 250r / min for 5 minutes and mix thoroughly to obtain a mixed system of coagulation, flocs and circulating water, pump the circulating water after flocculation and settlement to the filter screen, and make the coagulation and flocs in the circulation and treatment After the waste water is separated, the circulating water after filtration is sent back to the spray booth for further use.

Embodiment 2

[0026] The paint spraying room uses circulating water to collect paint mist. After a certain number of shifts, the concentration of water-based paint in the circulating water reaches above 10% (mass fraction), the circulating water looks turbid, and the COD reaches above 8,500. Add 3.4% (mass fraction) coagulant PFC into the circulating water of water-based epoxy paint, first stir at 250r / min for 1min, then stir at 50r / min for 5min, then let the circulating water stand for 15min, then add Flocculant PAM, stir at 250r / min for 5 minutes and mix thoroughly to obtain a mixed system of coagulation, flocs and circulating water, pump the circulating water after flocculation and settlement to the filter screen, and make the coagulation and flocs in the circulation and treatment After the waste water is separated, the circulating water after filtration is sent back to the spray booth for further use.

Embodiment 3

[0028] The paint spraying room uses circulating water to collect paint mist. After a certain number of shifts, the concentration of water-based paint in the circulating water reaches more than 10% by mass, the circulating water looks turbid, and the COD reaches more than 8,500. Add the coagulant PFS with a mass fraction of 3.4% to the circulating water of the water-based epoxy paint, first stir at a speed of 250r / min for 1min, then stir at a speed of 50r / min for 5min, then let the circulating water stand for 15min, and then add the flocculant PAM, stir at 300r / min for 1min and mix thoroughly to obtain a mixed system of coagulation, floc and circulating water, pump the circulating water after flocculation and settlement to the filter screen, and make the coagulation and floc in the circulating water and the treated wastewater Separation, after filtration, the circulating water is sent back to the spray booth for further use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com