Method and device for reflow soldering with volume flow control

A volume flow and brazing technology, applied in the direction of manufacturing tools, welding equipment, electrical solid devices, etc., can solve the problems of increased failure rate, overheating of small parts, etc., to improve temperature distribution, maintain temperature distribution, and high energy utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

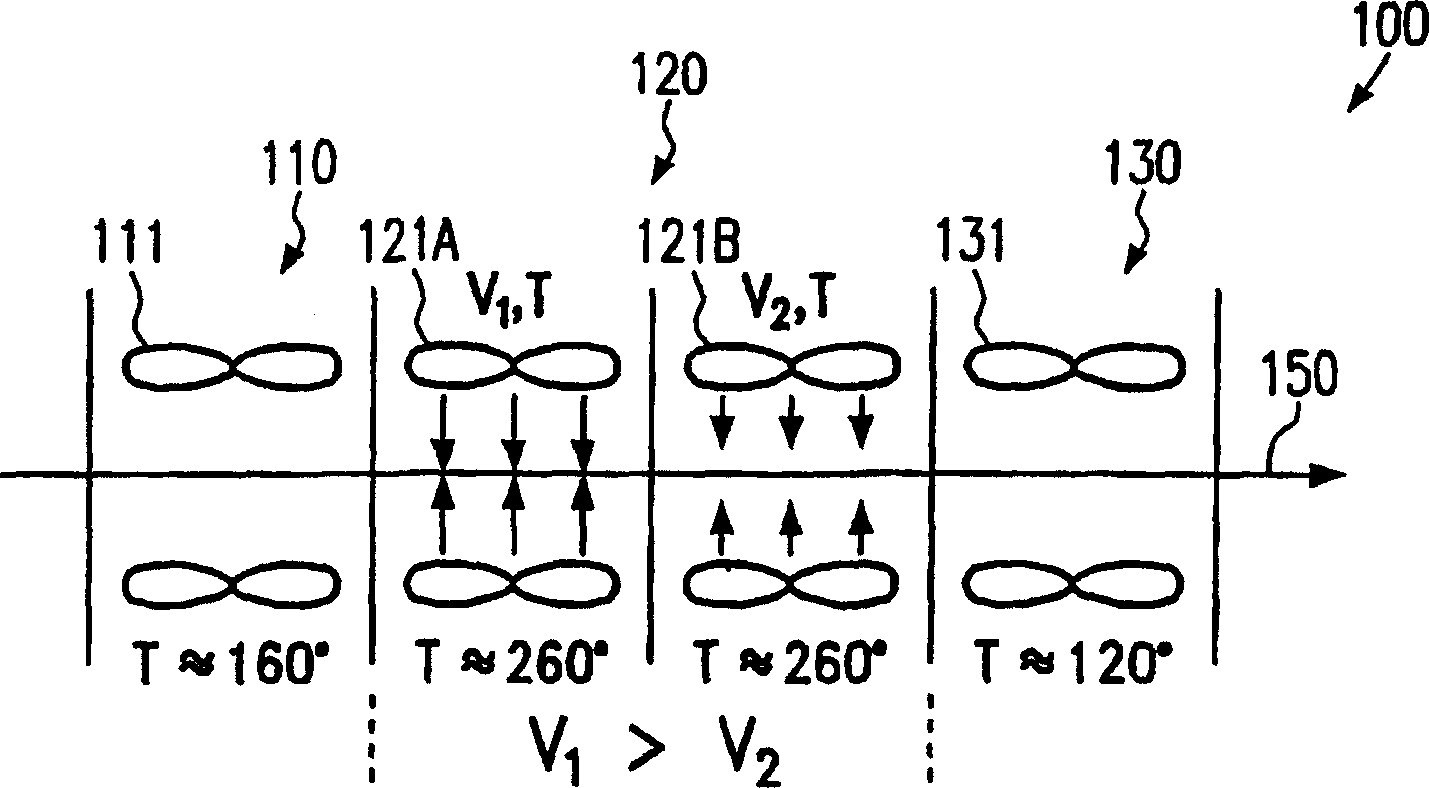

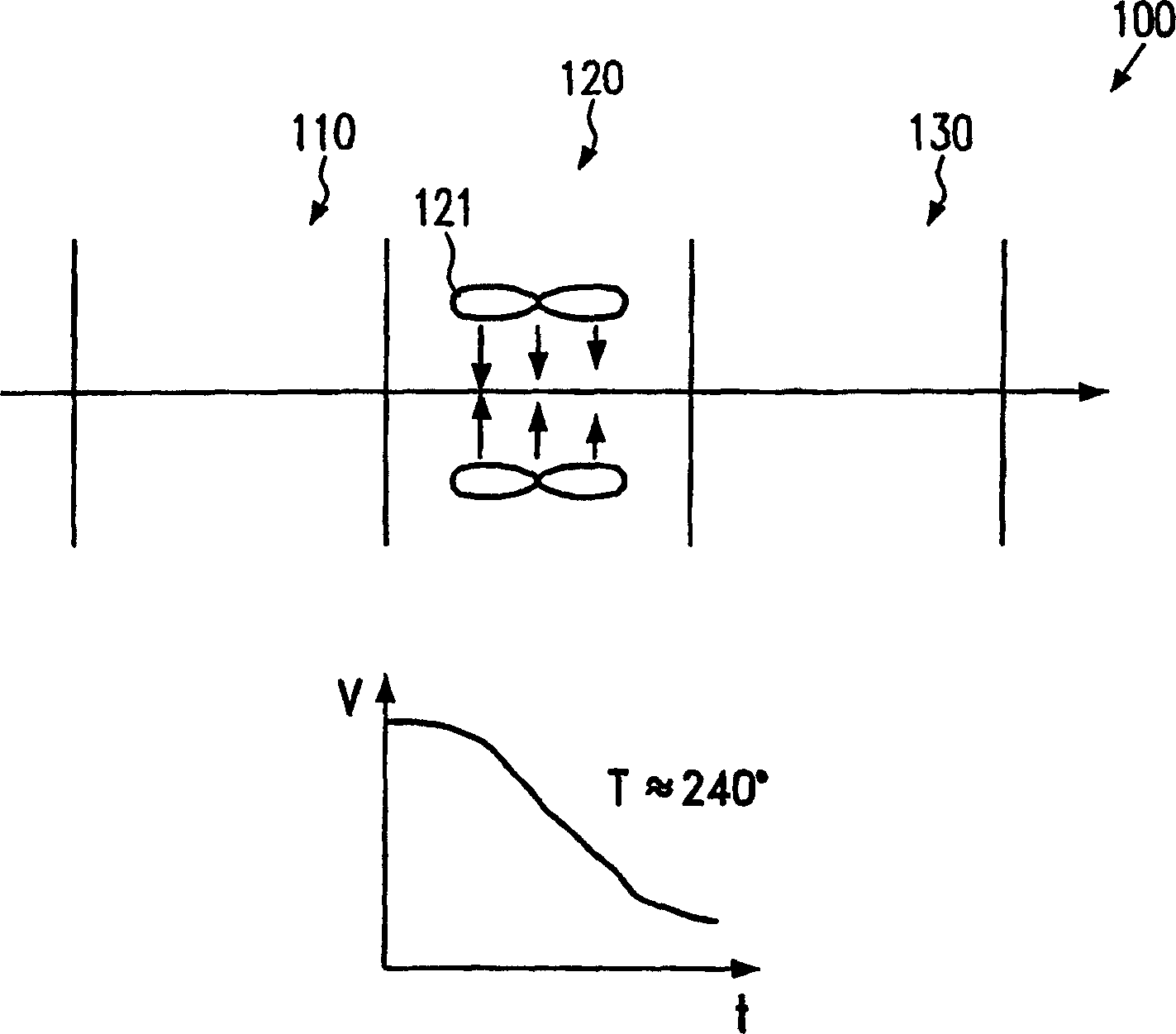

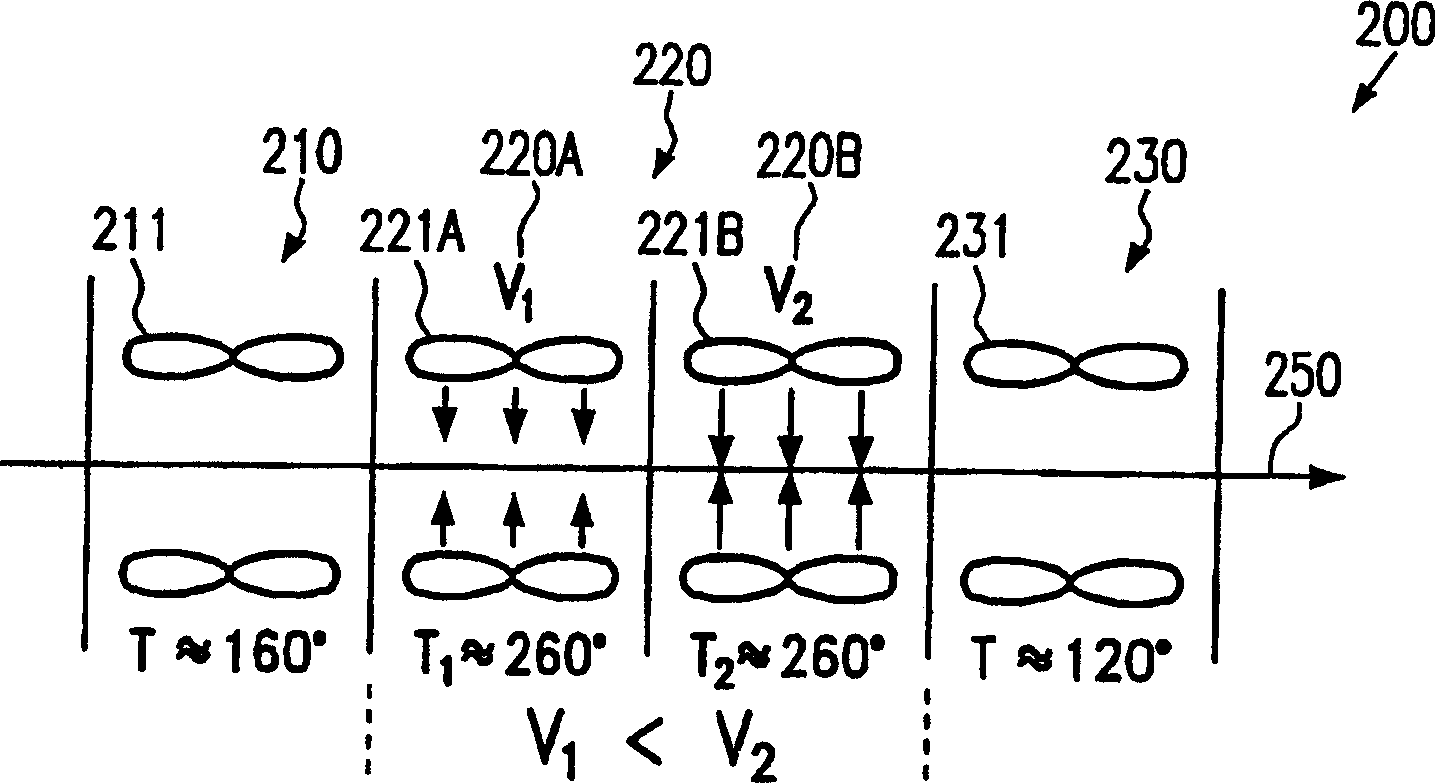

[0032] Figure 1a An example of a reflow soldering apparatus in the form of a transfer furnace 100 is schematically shown. In the example shown, the apparatus comprises at least a preheating zone 110, a brazing zone 120 and a cooling zone 130. In addition, a conveying device 150 is provided which conveys objects to be soldered (not shown), for example in the form of electronic circuit boards with various parts mountable with solder paste, through the respective zones 110 , 120 and 130 . In the example shown, the brazed region 120 is subdivided into two parts 120a and 120b. In section 120a, a volumetric flow of hot gas at a specific temperature T is directed via a first convective heater 121a onto a conveying device 150, or onto an object to be brazed thereon. Similarly, the brazing section 120b includes a convection heater unit 121b which directs a predetermined volume flow of hot gas at a specific temperature T onto the delivery device 150 or optionally onto the objects to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com