Production line adaptation method and system based on industrial internet of things

An industrial Internet of Things and production line technology, applied in the direction of comprehensive factory control, data processing application, electrical program control, etc., can solve the problems of low compatibility of industrial Internet of Things systems, and achieve the effects of easy promotion and application, flexible management and control, and fine management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

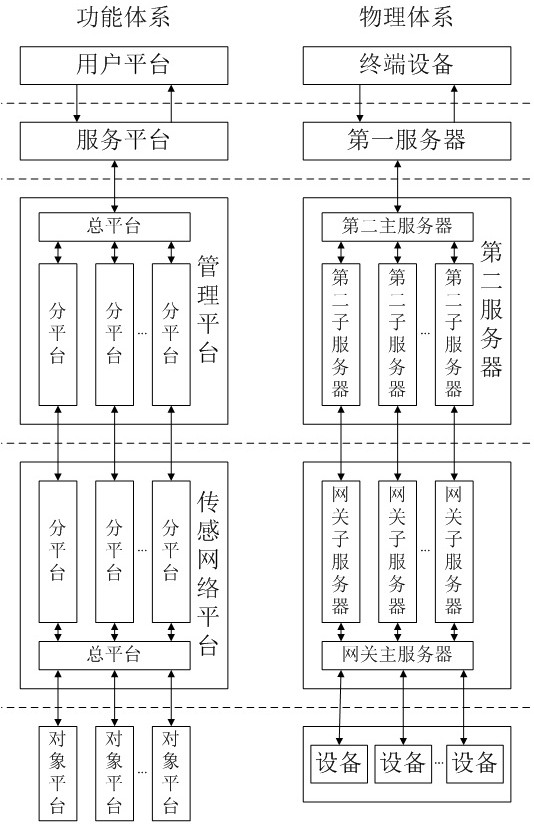

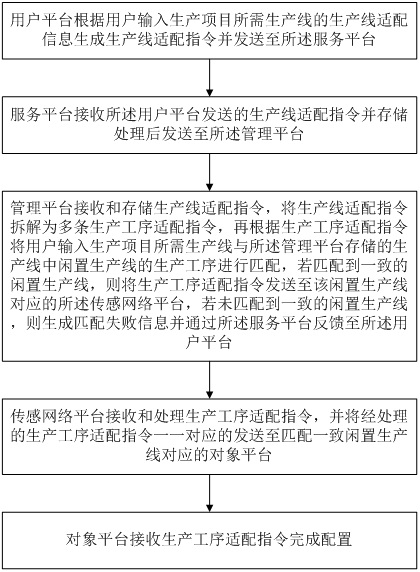

[0030] like figure 1 As shown, the production line adaptation system based on the Industrial Internet of Things includes a user platform, a service platform, a management platform, a sensor network platform and an object platform that interact in sequence; wherein: the user platform is configured as a terminal device that interacts with users, receives The user inputs the information and processes it and sends it to the service platform, and displays the information sent by the service platform to the user; the service platform is configured as a first server, receives the information sent by the user platform, stores and processes it, and sends it to the management platform, and obtain the information required by the user from the management platform, store and process it, and send it to the user platform; the management platform, configured as a second server, receives and stores the information sent by the service platform. The control object platform performs parameter conf...

Embodiment 2

[0037] This embodiment makes the following further limitations on the basis of Embodiment 1: the service platform of this embodiment adopts a centralized arrangement, and the centralized arrangement means that the platform uniformly receives data, uniformly processes data, and uniformly sends data. The management platform in this embodiment adopts a front-sub-platform arrangement. The front-sub-platform arrangement means that the management platform is provided with a main platform and a plurality of sub-platforms, and the transmission of control information and object platform parameter configuration information is transmitted from the main platform to the sub-platforms , the perception information is transmitted from the sub-platform to the main platform. In this embodiment, the main platform of the management platform is configured as the second main server, and its sub-platforms are configured as the second sub-servers, the main platform of the management platform receives ...

Embodiment 3

[0040] This embodiment makes the following further limitation on the basis of Embodiment 1 or Embodiment 2: when the management platform of this embodiment does not match the idle production line that is consistent with the production line required by the production item, the management platform also calculates the production item. The first matching ratio between the required production line and all idle production lines, screen the idle production line with the highest first matching ratio and obtain the production process missing from the idle production line, and then match the production process adaptation instruction corresponding to the missing production process in the idle production line with The remaining idle production lines are matched, and then the information of the idle production lines with the highest matching rate and the matching results of the missing production processes in the remaining idle production lines are sent to the service platform, and the match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com