Method and system for correcting programming and optimising treatment processes

一种加工过程、计划的技术,应用在计算、数据处理应用、仪器等方向,能够解决自动化不出现、较差质量废品等问题,达到效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

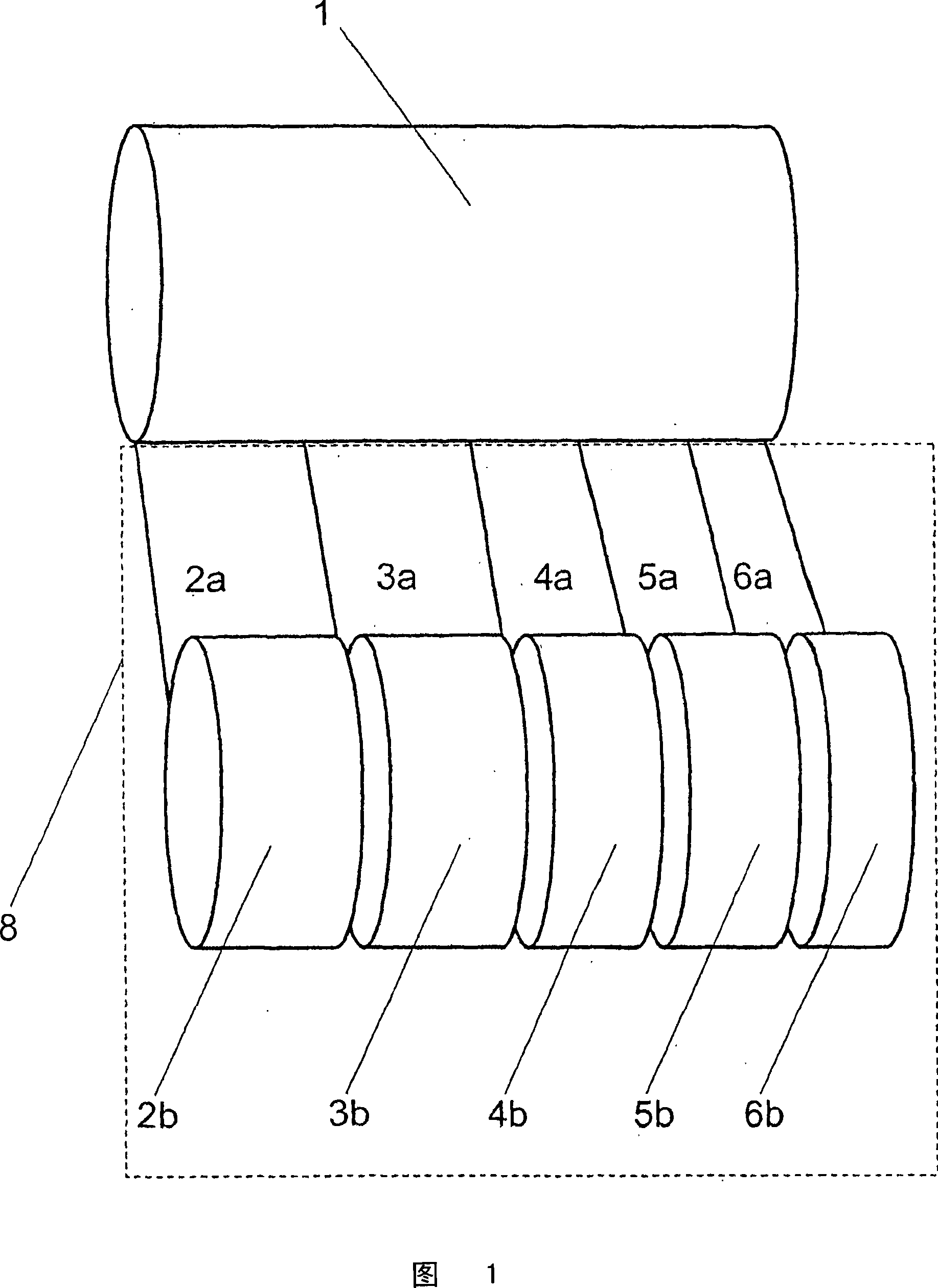

[0032] exist figure 1 In , the tape wound on a large-format tape reel is segmented or cut 8 into multiples, a total of five narrow tapes 2a, 3a, 4a, 5a, 6a are shown here, which are themselves Winding onto small format tape reels 2b, 3b, 4b, 5b, 6b. The division of the original large-format tape reel takes place here in one dimension, ie only in one direction. Wherein the cut edge is parallel to the flow direction of the tape and thus perpendicular to the axis of the reel. The result of the shearing 8 gives the impression of subdividing the large format roll 1 into individual trays 2b, 3b, 4b, 5b, 6b of various thicknesses.

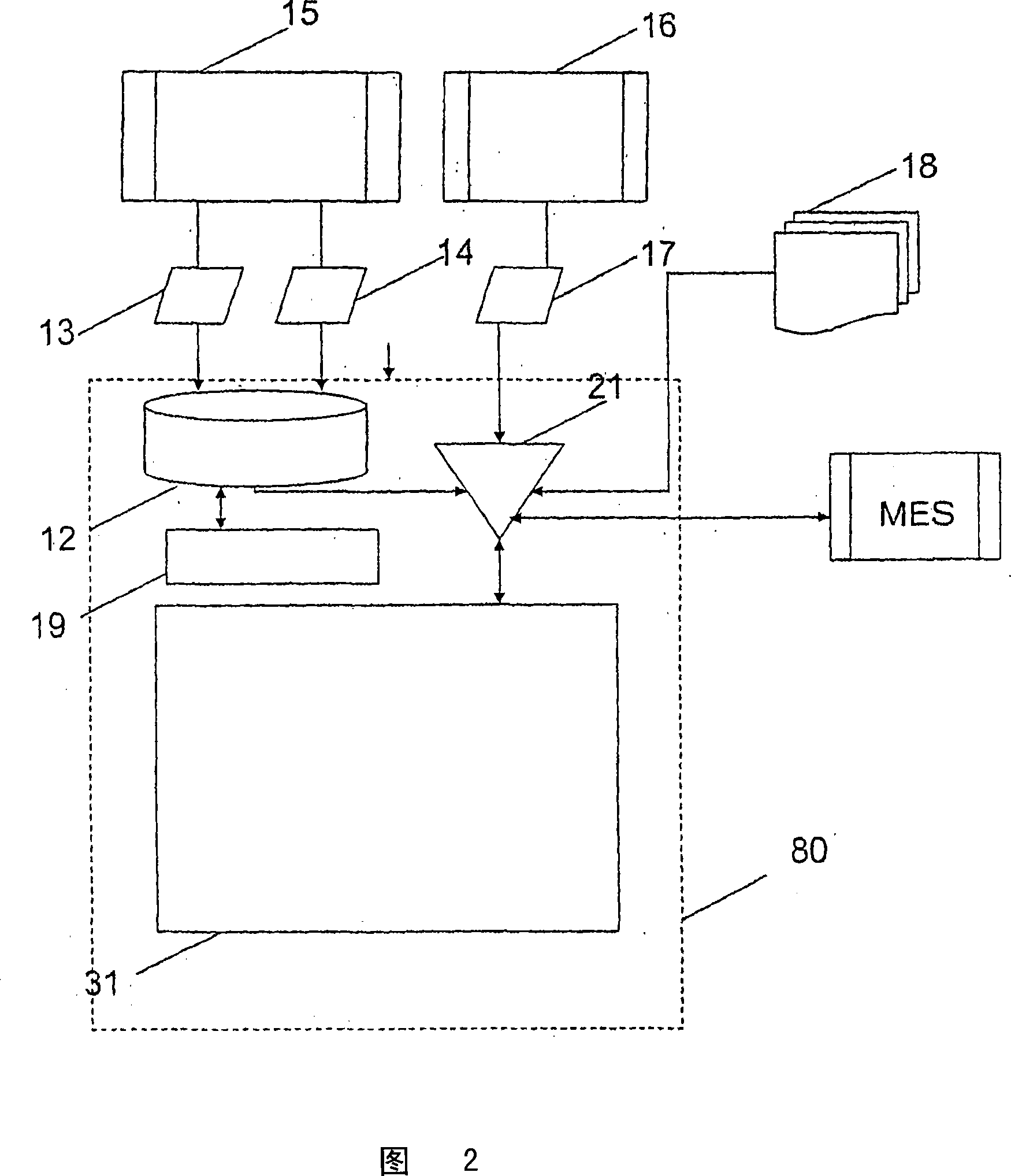

[0033] exist figure 2 An exemplary embodiment of the system of the present invention is represented in . The system represented here for the adaptive optimization of the corresponding processing and / or further processing, which here is the cutting of large-format paper cylinders, also called "jumbo rolls", cut, comprising a correspondingly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com