Double-toggle double-motor parallel-drive toggle rod mechanism and control method thereof

A driving mechanism and dual-motor technology, which is applied to the driving device of forging presses, presses, punching machines, etc., can solve the problems of nominal pressure stroke and maximum stroke limitation, fluctuation of boost ratio, and reduction of total power of servo motor, etc. Achieving the effect of reducing power capacity, reducing complexity, and reducing drive torque requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

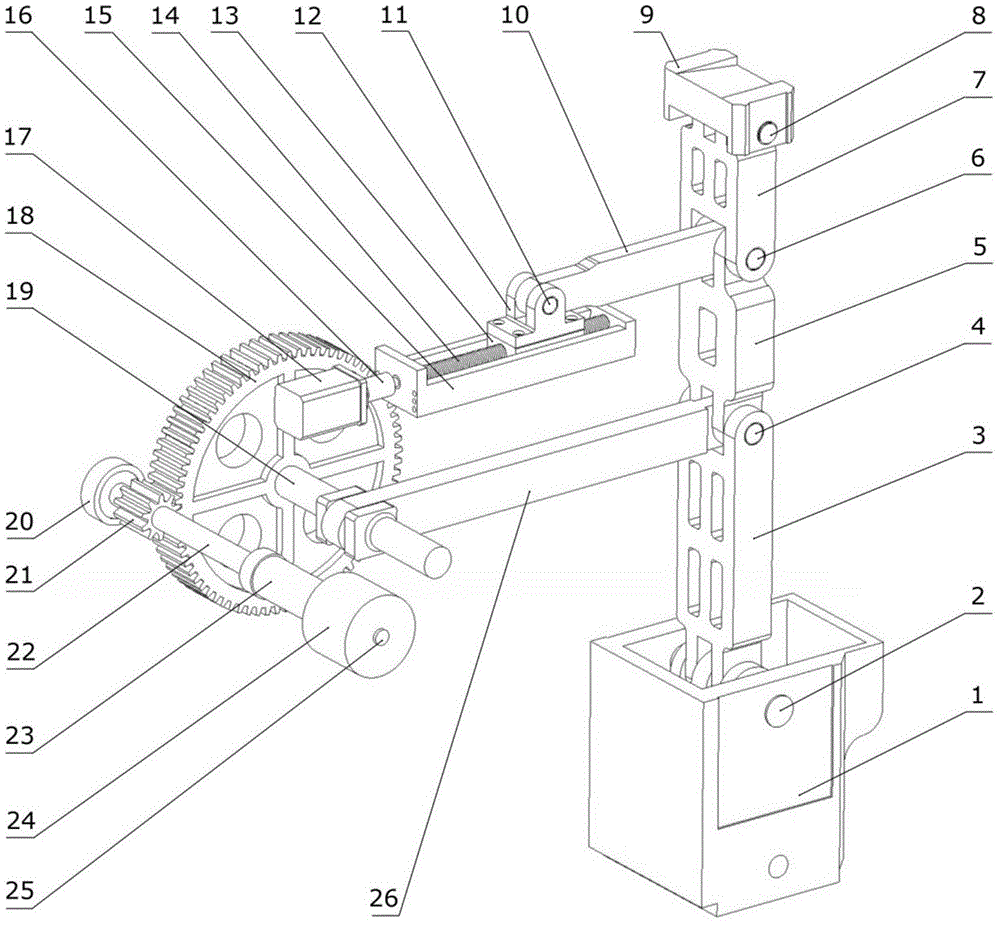

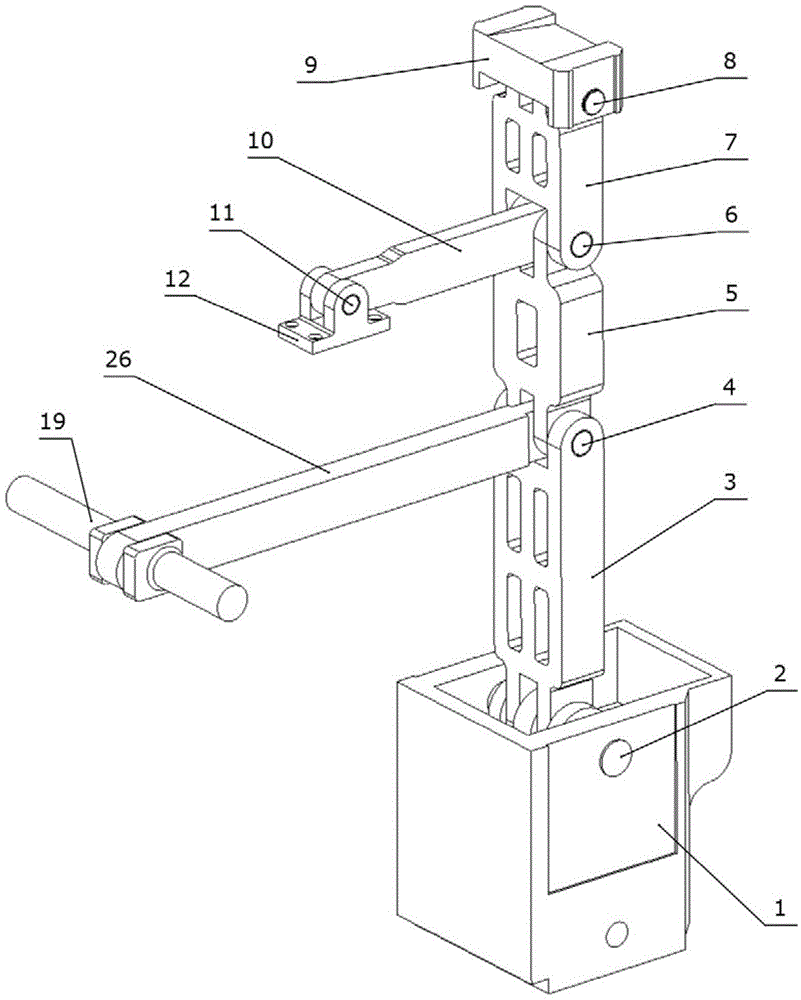

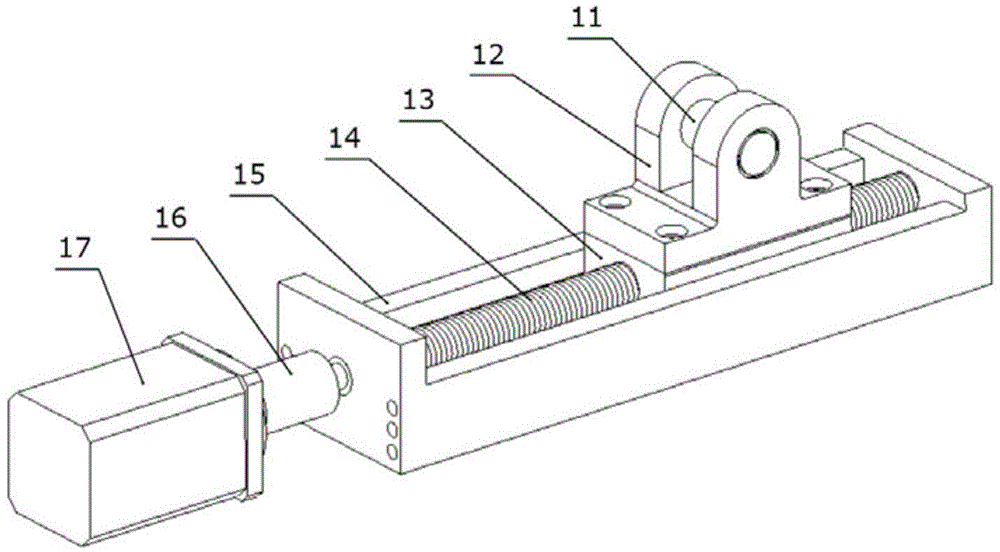

[0040] figure 1 As shown, it is a schematic diagram of the structure of the dual-knuckle dual-motor parallel-driven toggle mechanism of this embodiment. The double-knuckle dual-motor parallel-driven toggle mechanism is characterized in that it is a two-degree-of-freedom parallel mechanism, including a double-knuckle bearing mechanism, an upper The toggle adjustment mechanism, the lower toggle drive mechanism, and the double toggle bearing mechanism include two toggles, the upper toggle and the lower toggle. The upper toggle adjustment mechanism and the lower toggle drive mechanism are distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com