Production method of dentritic morphology nickel powder

A production method and dendritic technology are applied in the production field of dendritic nickel powder, and can solve the problems of high preparation cost, high production cost, depleted nickel-containing raw materials and solutions, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

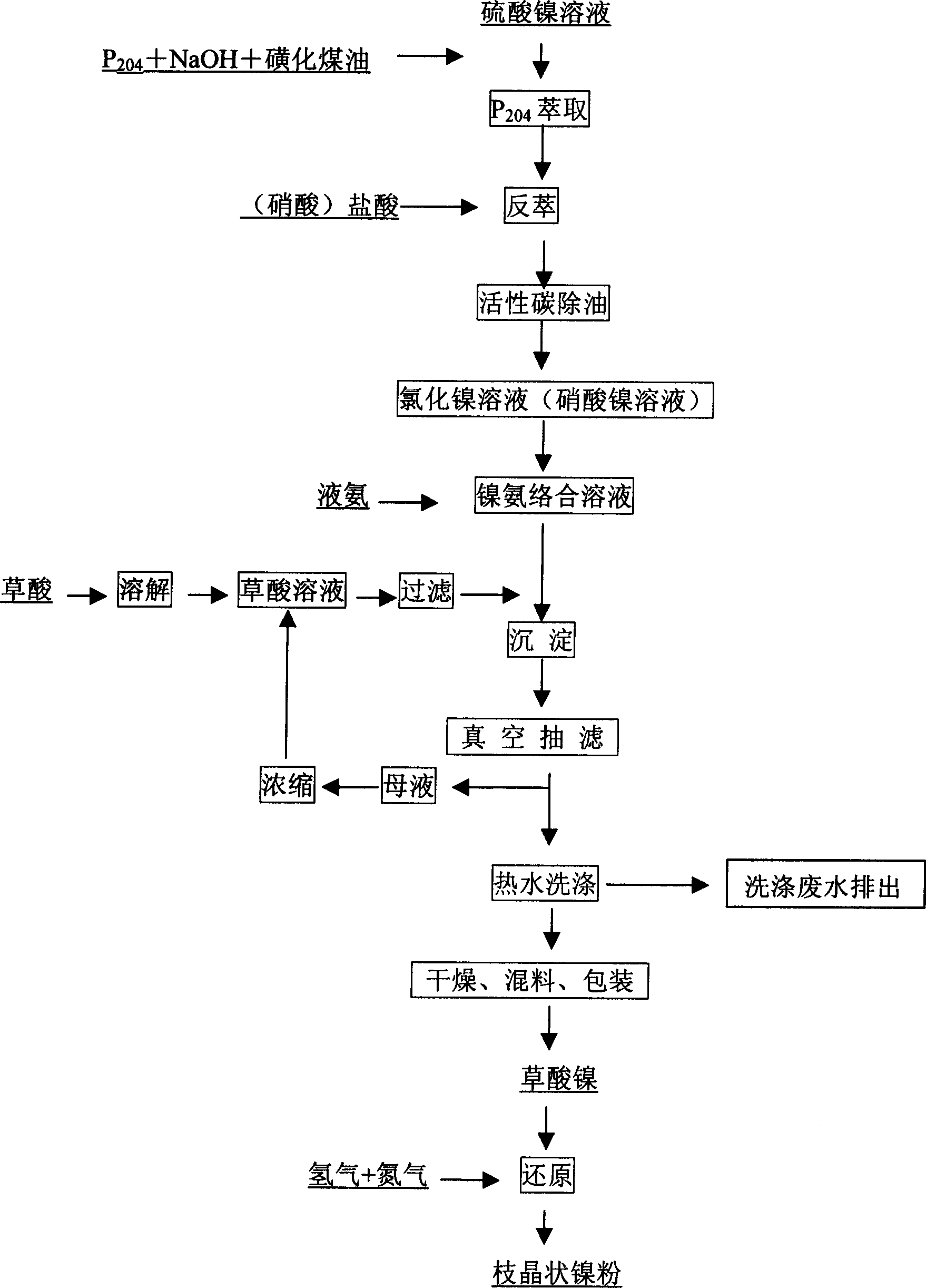

Method used

Image

Examples

example 1

[0023] Adopt the calcium-removing magnesium feed liquid of the nickel sulfate production system; take P 204 The full extraction process uses 3.5N acidity hydrochloric acid (HCl) for back extraction, and the concentration of the back extraction solution is: 70-80g / l. The solution of the prepared nickel chloride is adsorbed by activated carbon, and the removal rate of organic matters is 90%. After removing the organic matter, pump the solution into the reaction kettle, dilute it with reverse osmosis pure water to 35g / l, pass liquid ammonia to adjust the pH of the solution to 8, and make nickel ions form nickel ammonium complex ions; prepare about 100g / l The oxalic acid solution is filtered and poured into the high level tank for use.

[0024] Beat 200 liters of nickel chloride solution with a nickel content of 35g / l to 0.5m 3 In the reaction kettle, pass liquid ammonia to adjust the pH to 8.2, add 0.50% PVP or sodium citrate additive according to the amount of nickel, heat the...

Embodiment 2

[0030] Other conditions are the same as example 1, back-extract with hydrochloric acid (HCl) of 3N acidity, prepare the solution of 70~80g / l nickel chloride and absorb through activated carbon, the organic matter removal rate is 90%. After removing the organic matter, pump the solution into the reaction kettle, dilute it with reverse osmosis pure water to 50g / l, pass liquid ammonia to adjust the pH of the solution to 8.3, and make nickel ions form nickel ammonium complex ions; prepare about 100g / l The oxalic acid solution is filtered and poured into the high level tank for use.

[0031] Beat 200 liters of nickel chloride solution with a nickel content of 50g / l to 0.5m 3 In the reaction kettle, pass liquid ammonia to adjust the pH to 8.5, add 0.6% PVP or sodium citrate additive according to the amount of nickel, heat the solution with steam until the solution temperature is 70°C, start to add 100g / l oxalic acid solution dropwise, and pass a small amount of Liquid ammonia, keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com