a method of crystallization

A technology of crystallization and cooling crystallization, applied in the direction of solution crystallization, can solve the problems of hindered crystallization process, affect heat exchange, vicious circle, etc., achieve the effect of favorable solid-liquid separation, improve energy efficiency coefficient, and wide range of process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

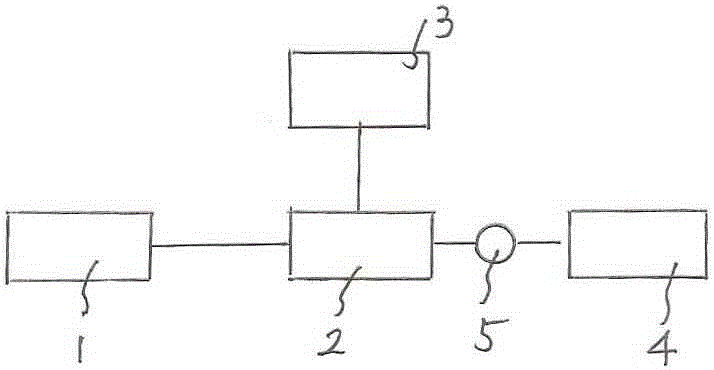

[0018] A crystallization method, a part of the mother liquor in the centrifuge mother liquor collection container (tank or pool, etc.) 1 is pumped to the front section for use, and the other part is transferred to the low-temperature mother liquor preparation tank 2 through the mother liquor pump, and the low-temperature mother liquor preparation tank The mother liquor is connected with the low-temperature water preparation unit 3 through the low-temperature mother liquor circulation pump, and the mother liquor is used as the refrigerant, and the mother liquor is cooled by the low-temperature water preparation unit to maintain the temperature of the mother liquor in the low-temperature mother liquor preparation tank within the set range; The mother liquor is pumped to each mixing and cooling crystallization kettle 4 through the low-temperature mother liquor pump 5, and mixed with hot materials in the mixing and cooling crystallization kettle. After the temperature in the mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com