Harmless treatment device and process for steel pickling waste liquid

A technology for iron and steel pickling waste liquid, harmless treatment, applied in the direction of metallurgical wastewater treatment, oxidized water/sewage treatment, filtration treatment, etc., can solve the problems of increasing the cost burden of enterprises, lack of practical application, and high technical requirements , to achieve the effect of clear and transparent water quality, small footprint and wide range of process adaptation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

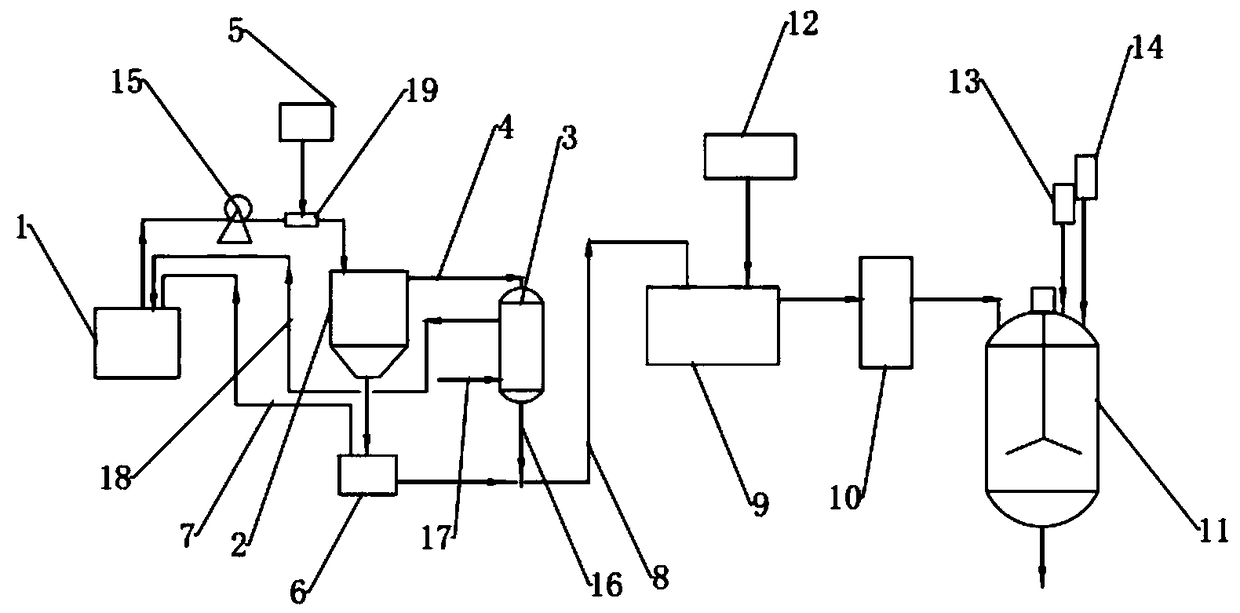

[0038] A kind of harmless treatment process of iron and steel pickling waste liquid, comprises the following steps:

[0039] (1) The acidic iron-containing ion waste liquid in the waste liquid storage tank 1 is mixed with the sodium hydroxide solution in the lye tank 5 in the Venturi mixer 19, and the mixed solution enters the settling tank 2 for reaction, and the pH value of the mixed solution is controlled In 7.5, make the waste solution H + with OH - combine into water to remove acid, and at the same time, make Fe 2+ , Fe 3+ respectively generate Fe(OH) 2 , Fe(OH) 3 Precipitation, sediment and water are separated in the sedimentation tank 2, and the water enters the sand filter tank 3 to further remove suspended impurities, and the clean water is discharged from the clean water drainage pipe 16 for reuse. The backwash water pipeline 17 is pumped into clear water to backwash the sand filter tank 3, and the backwash water is discharged into the waste liquid storage tank ...

Embodiment 2

[0044] A kind of harmless treatment process of iron and steel pickling waste liquid, comprises the following steps:

[0045] (1) The acidic iron-containing ion waste liquid in the waste liquid storage tank 1 is mixed with the sodium hydroxide solution in the lye tank 5 in the Venturi mixer 19, and the mixed solution enters the settling tank 2 for reaction, and the pH value of the mixed solution is controlled At 9, make the waste solution H + with OH - combine into water to remove acid, and at the same time, make Fe 2+ , Fe 3+ respectively generate Fe(OH) 2 , Fe(OH) 3 Precipitation, sediment and water are separated in the sedimentation tank 2, and the water enters the sand filter tank 3 to further remove suspended impurities, and the clean water is discharged from the clean water drainage pipe 16 for reuse. The backwash water pipeline 17 is pumped into clear water to backwash the sand filter tank 3, and the backwash water is discharged into the waste liquid storage tank 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com