Waste gas recovery device of chemical reaction kettle

A chemical reaction and exhaust gas recovery technology, which is applied in the direction of incinerators, chemical instruments and methods, and combustion methods, can solve problems such as low recovery efficiency, energy waste, and environmental pollution, achieve high recycling rates, eliminate environmental pollution, prevent The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

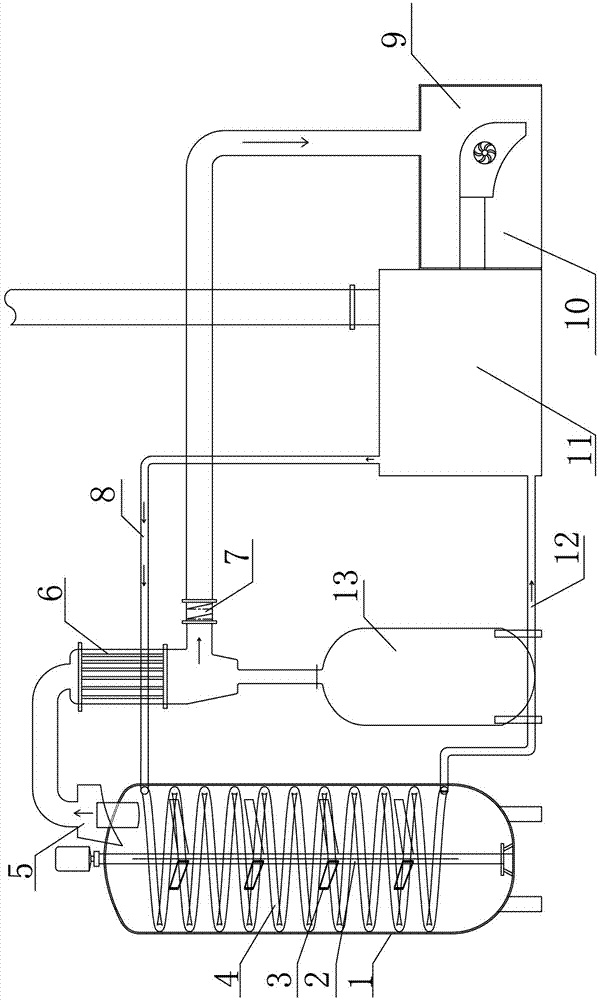

[0012] A device for recycling waste gas from chemical reactors, such as figure 1 As shown, a vertical stirring shaft 2 driven by a motor is arranged in the center of the tank body 1 of a chemical reaction kettle, stirring blades 3 are evenly distributed on the stirring shaft 2, and a spiral shaft is arranged in the tank body 1 outside the stirring blade 3. The heating pipe 4 is used to heat the heat transfer oil boiler 11 through the burner connected to the blower 9 in the closed combustion engine room 10. The oil outlet pipe 8 of the boiler 11 is connected to the inlet of the spiral heating pipe 4, and the oil return pipe 12 of the boiler 11 is connected to the spiral heating pipe 4. The outlet of the tank body 1 is equipped with a gas collection hood 5 on the exhaust pipe provided on the top of the tank body 1. The gas delivery pipeline of the gas collection hood 5 is connected to the inlet of the condenser 6, and the gas outlet of the condenser 6 is connected through a one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com