Ceramic dielectric material and manufacture method thereof and ceramic capacitor and manufacture method thereof

A technology of ceramic capacitors and ceramic dielectrics, applied in fixed capacitor electrodes, fixed capacitor dielectrics, fixed capacitor components, etc., can solve the problem of high cost of capacitor materials, and achieve reduced material costs, excellent dielectric properties, and large The effect of profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

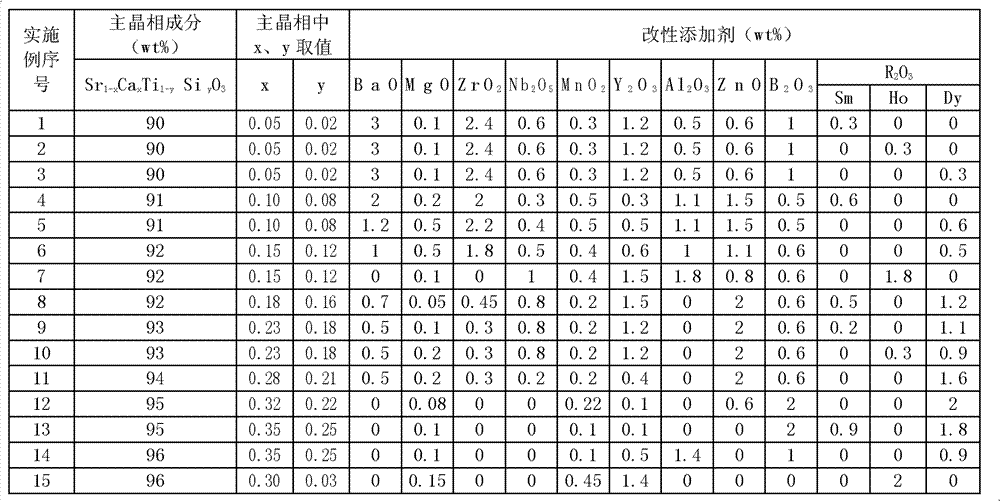

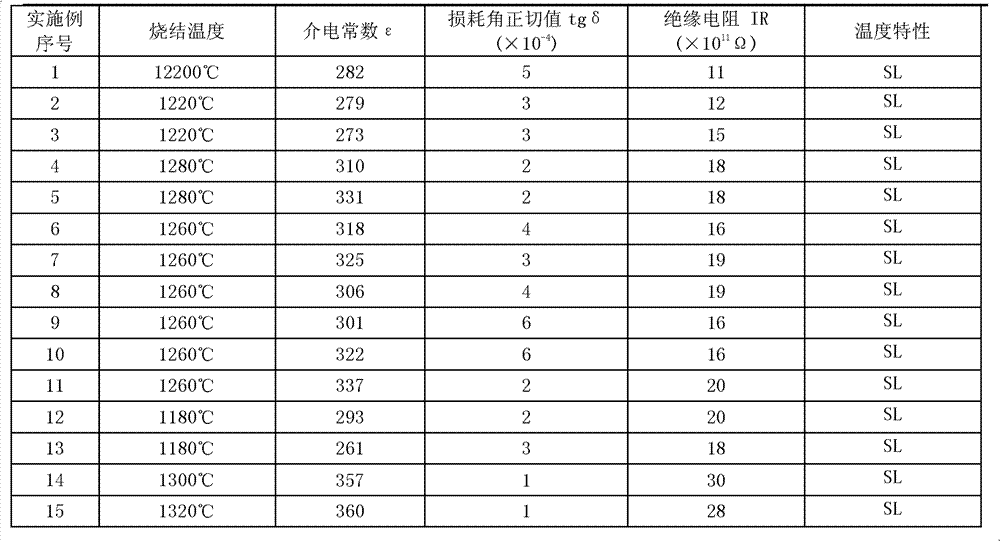

[0031] A ceramic dielectric material, mainly composed of main crystal phase components and modifying additives, including trace unavoidable impurities; Sr synthesized by solid phase method 1-x Ca x Ti 1-y Si y o 3 (Where 0.05≤x≤0.35, 0.02≤y≤0.25) as the main crystal phase component, the proportion of the main crystal phase component and the modification additive in the composition of the dielectric material in terms of mass percentage is 90-96% respectively And 10~4%; Modification additives are selected from BaO, MgO, ZrO 2 , Nb 2o 5 , MnO 2 , Y 2 o 3 、Al 2 o 3 , ZnO, B 2 o 3 , R 2 o 3 (R is at least one of Sm, Ho, Dy) four or more; the mass percentage of various oxides in the modified additive in the dielectric material is: BaO accounts for 0-3 %, MgO accounts for 0.05~0.5%, ZrO 2 Occupying 0~2.5%, Nb 2 o 5 0~1%, MnO 2 Accounting for 0.05~0.5%, Y 2 o 3 Accounting for 0.1~1.5%, Al 2 o 3 0~2%, ZnO 0~2%, B 2 o 3 Occupies 0~2%, R 2 o 3 Accounted for 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com