Reduction-resistant Y5P ceramic capacitor dielectric porcelain

A technology of ceramic medium and mass percentage, which is applied in the field of anti-reduction ceramic dielectric materials and its preparation, can solve problems such as increase in loss tangent value, decrease in capacitor insulation resistance, and decrease in cost of ceramic capacitor materials, achieving good dispersion and excellent dielectric properties. Electrical performance, highlighting the effect of market competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these examples.

Embodiment

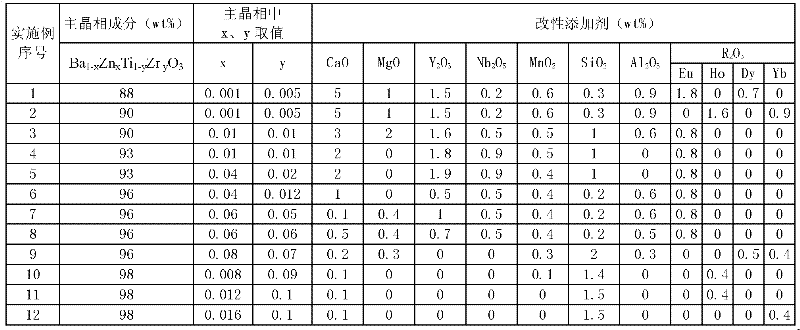

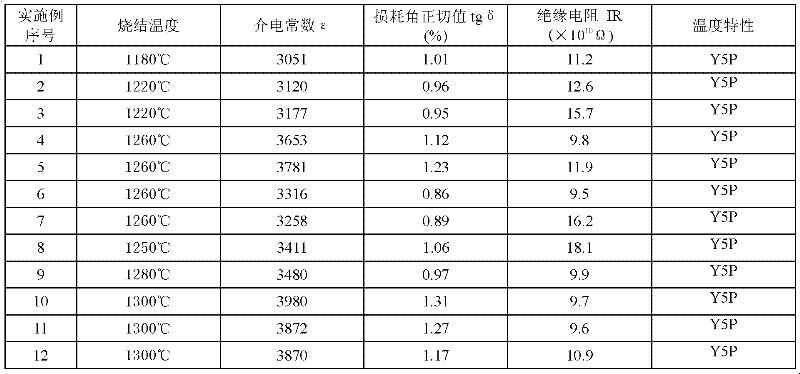

[0013] (1) In the main crystal phase composition Ba of the present invention 1-x Zn x Ti 1-y Zr y o 3 (where 0.001≤x≤0.10, 0.005≤y≤0.10), weigh BaCO according to mass percentage 3 , ZnO, TiO 2 and ZrO 2 Perform ingredients, mix and place in a ball mill according to the composition ratio in Table 1, add the same deionized water according to the mass ratio, mix and ball mill for 12 hours, then dry the slurry, pulverize it, and place it in a high-temperature resistance furnace set at 1200°C Insulation for 4 hours synthesizes Ba 1-x Zn x Ti 1-y Zr y o 3 powder.

[0014] (2) with CaO, MgO, Y 2 o 3 , Nb 2 o 5 , MnO 2 , SiO 2 、Al 2 o 3 , R 2 o 3 (R is at least one of Eu, Ho, Dy, and Yb) as raw materials, according to the composition ratio in Table 1, mix and place in a ball mill, add equal parts of deionized water to carry out wet ball milling, the slurry particle size after ball milling After the distribution meets the design requirements, the slurry is dried a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com