Carbon nano tube antistatic film and preparation method thereof

A carbon nanotube and antistatic film technology, applied in the field of carbon nanotube antistatic film and its preparation, can solve the problems of restricting the service life and application range, uneven dispersion of carbon nanotubes, limited antistatic ability, etc. Large-scale preparation, good light transmittance and conductivity, and the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

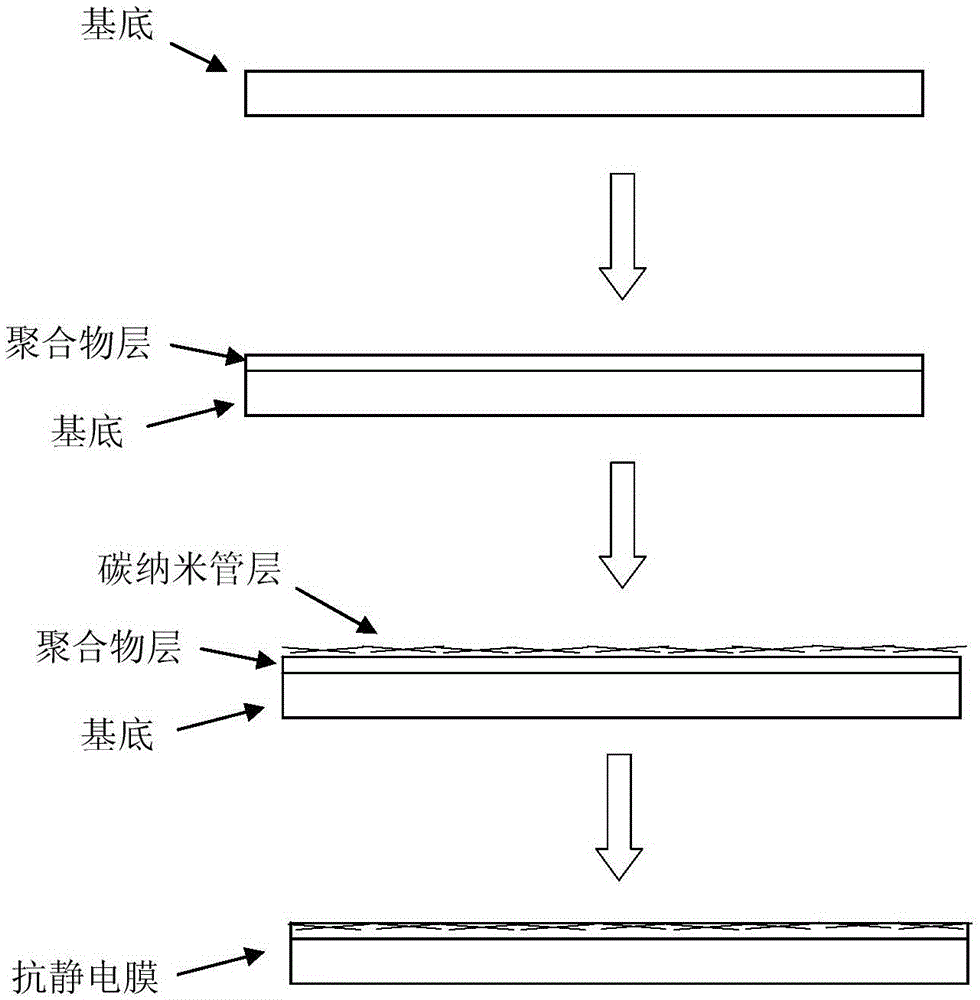

[0036] Example 1 please refer to figure 1 , the preparation method of a kind of carbon nanotube antistatic film provided in this embodiment comprises:

[0037] (1) Provide a polyvinyl alcohol aqueous solution with a concentration of about 0.01wt%, wherein the polyvinyl alcohol has a molecular weight of about 100,000 (the following are number average molecular weights unless otherwise specified); and, provide a concentration of about 0.01wt% carbon nanotube dispersion liquid, wherein the carbon nanotubes can be single-walled carbon nanotubes and / or multi-walled carbon nanotubes, and the solvent can be water;

[0038] (2) Coating the polyvinyl alcohol solution on the surface of PET (polyethylene terephthalate) film (visible light transmittance about 89%) by spraying, and obtaining a composite film after drying, wherein the polyvinyl alcohol The dry film thickness is about 500nm;

[0039] (3) Coating the carbon nanotube dispersion on the surface of the polyvinyl alcohol layer o...

Embodiment 2

[0042] Embodiment 2: the preparation method of a kind of carbon nanotube antistatic film provided in this embodiment comprises the steps:

[0043] (1) Provide a polyvinyl alcohol aqueous solution with a concentration of 5wt%, wherein the molecular weight of polyvinyl alcohol is about 20,000; and provide a carbon nanotube dispersion with a concentration of about 0.001wt%, wherein the carbon nanotubes can be single-walled carbon nanotubes And / or multi-walled carbon nanotubes, the solvent can be a mixed solvent of water and ethanol;

[0044] (2) Coating the polyvinyl alcohol solution on the surface of a polyethylene film (visible light transmittance about 70%) by dip coating, and drying to obtain a composite film, wherein the dry film thickness of polyvinyl alcohol is about 5 μm;

[0045] (3) Coating the carbon nanotube dispersion on the surface of the polyvinyl alcohol layer of the composite film, keeping the temperature at about 80° C. for about 10 minutes to volatilize and rem...

Embodiment 3

[0048] Embodiment 3: the preparation method of a kind of carbon nanotube antistatic film provided in this embodiment comprises the steps:

[0049](1) Provide a polyvinyl alcohol aqueous solution with a concentration of about 1wt%, wherein the molecular weight of the polyvinyl alcohol is about 50,000; and provide a carbon nanotube dispersion with a concentration of about 1wt%, wherein the carbon nanotubes can be single-walled carbon nanotubes and / or multi-walled carbon nanotubes, the solvent can be a mixed solvent of water and ethanol in any proportion;

[0050] (2) Coating the polyvinyl alcohol solution on the surface of a polypropylene film (visible light transmittance about 75%) by dip coating, and drying to obtain a composite film, wherein the polyvinyl alcohol dry film thickness is about 50 μm;

[0051] (3) Coating the carbon nanotube dispersion on the surface of the polyvinyl alcohol layer of the composite film, keeping it warm for about 2 hours at a temperature of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com