High-voltage plasma power supply

A plasma and power supply technology, applied in the application field of ion technology, can solve problems such as difficulty in meeting the needs of medium and high-power industrial waste gas treatment, unfavorable cost performance, unsuitable marketization, and unsuitability for large-scale use, achieving complete protection measures, easy promotion and application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

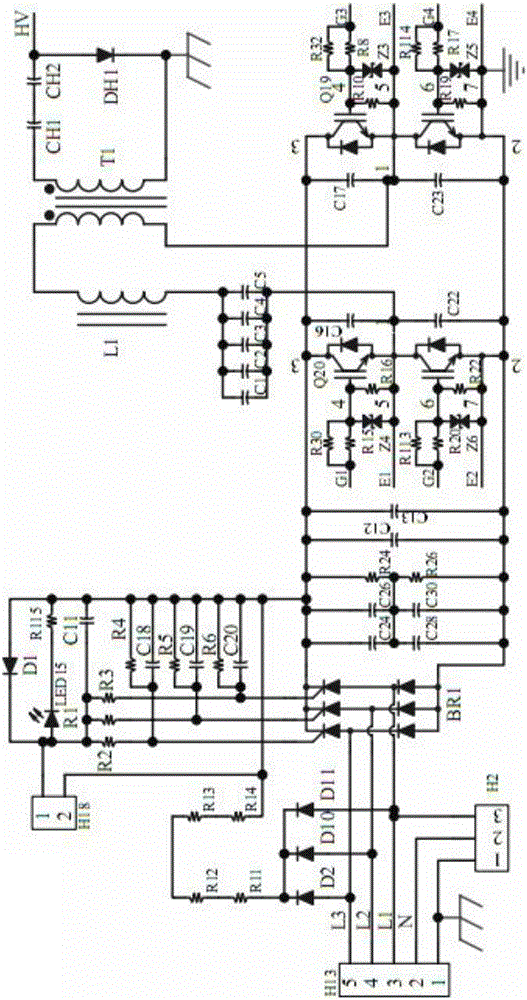

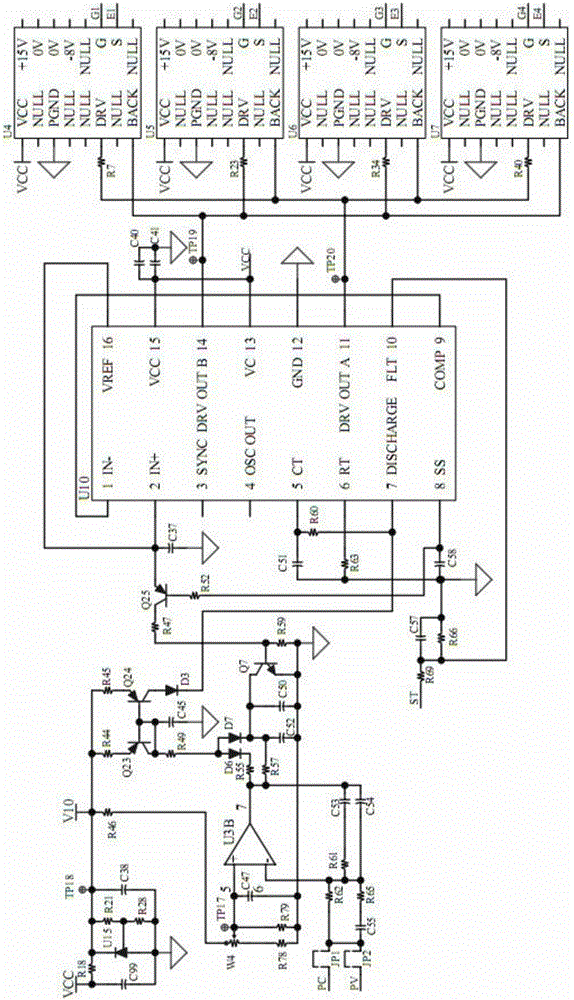

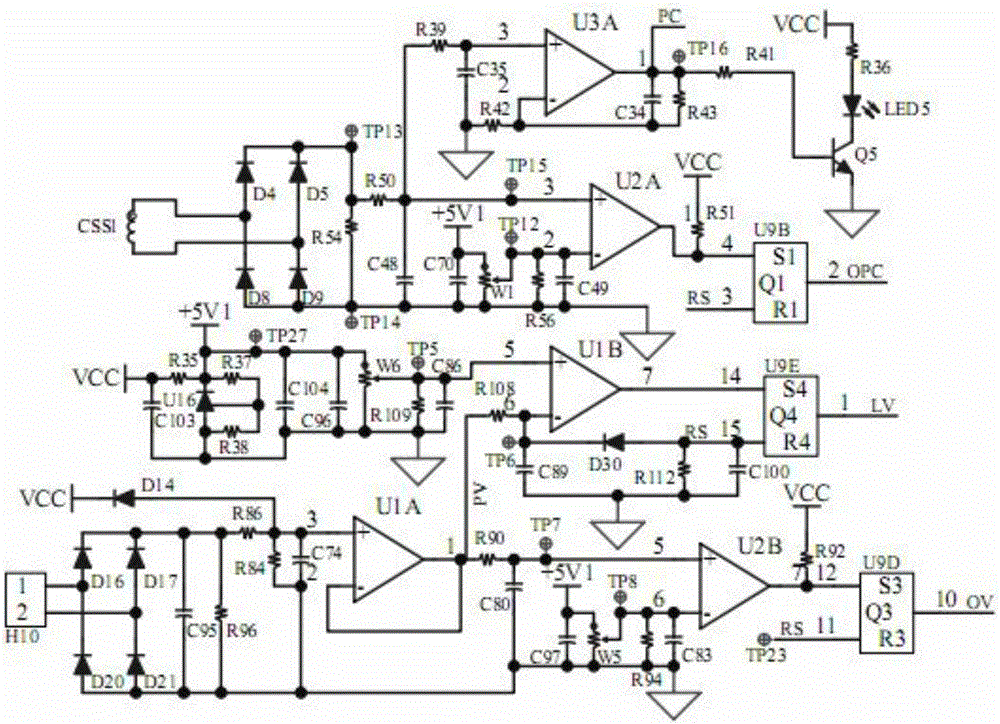

[0035] see Figure 1-Figure 5, a high-voltage plasma power supply, the plasma power supply includes a three-phase half-controlled rectifier circuit, a delay start circuit, a filter energy storage circuit, a full bridge circuit, an LC series resonant circuit, a voltage doubler rectifier circuit, a power regulation circuit, and a feedback control circuit circuit, frequency conversion circuit, IGBT full-bridge drive circuit, and alarm circuit, the three-phase half-controlled rectifier circuit is connected to a high-voltage transformer through a full-bridge circuit and an LC series resonant circuit, and the power regulation circuit and feedback control circuit are connected to a feedback control circuit. The feedback control circuit is connected with the full bridge drive circuit through the frequency conversion circuit. The three-phase half-controlled rectifier circuit is completed by half-controlled rectifier bridge BR1, controlled by resistors R1~6, capacitors C11, C18~20, diod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com