Bulk acoustic wave resonator and manufacturing method thereof, filter and duplexer

A technology of bulk acoustic wave resonator and resonance area, which is applied in the field of wireless communication, can solve the problems of thin film deposition, etching precision limitation, difficulty in realizing thin film bulk acoustic wave duplexer, and inability to manufacture frequency difference resonators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0055] The present disclosure proposes a three-dimensional (XYZ three-dimensional) mass loading structure for tuning the frequency of a thin film bulk acoustic resonator. The three-dimensional mass load structure described in the present disclosure includes:

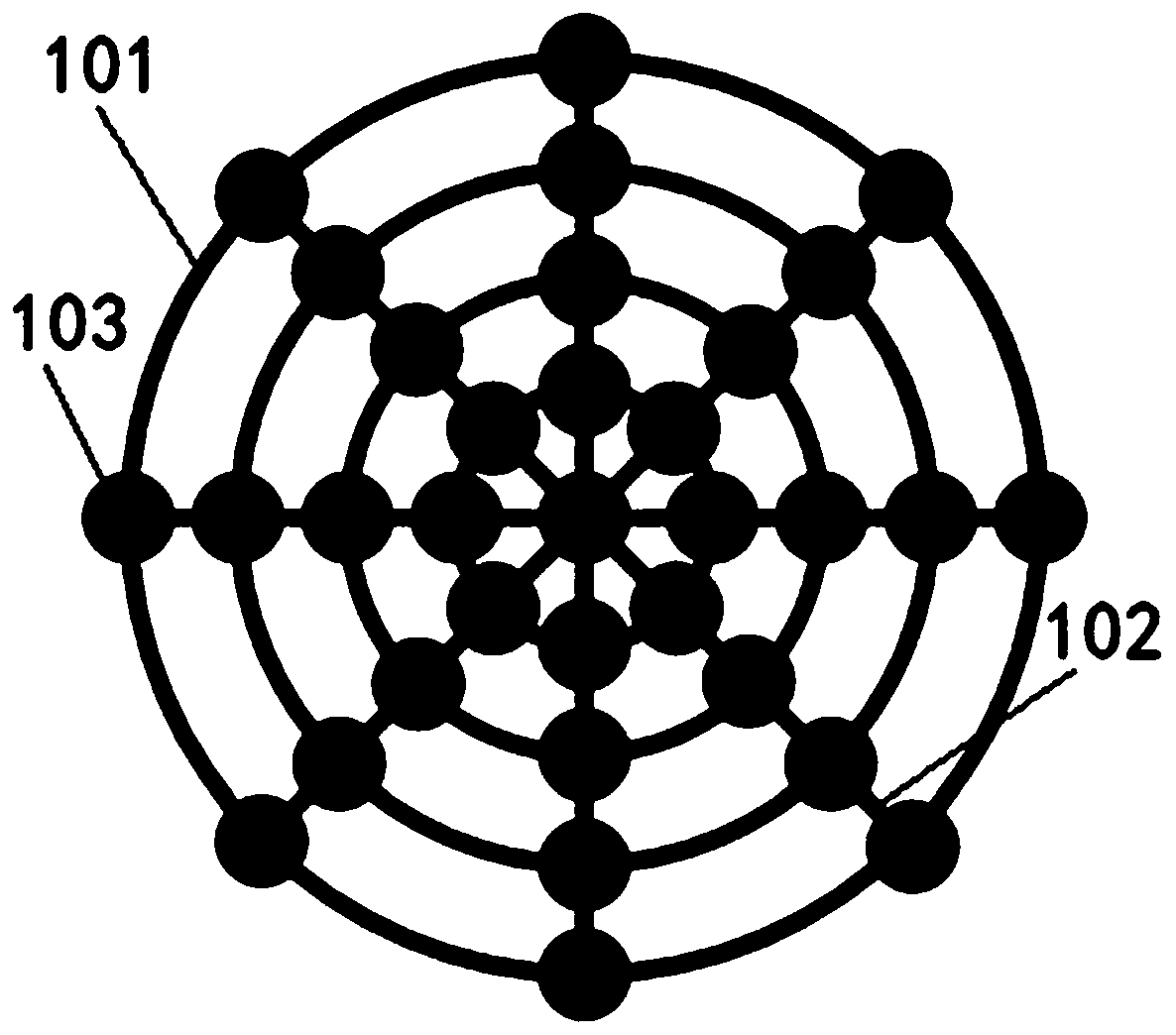

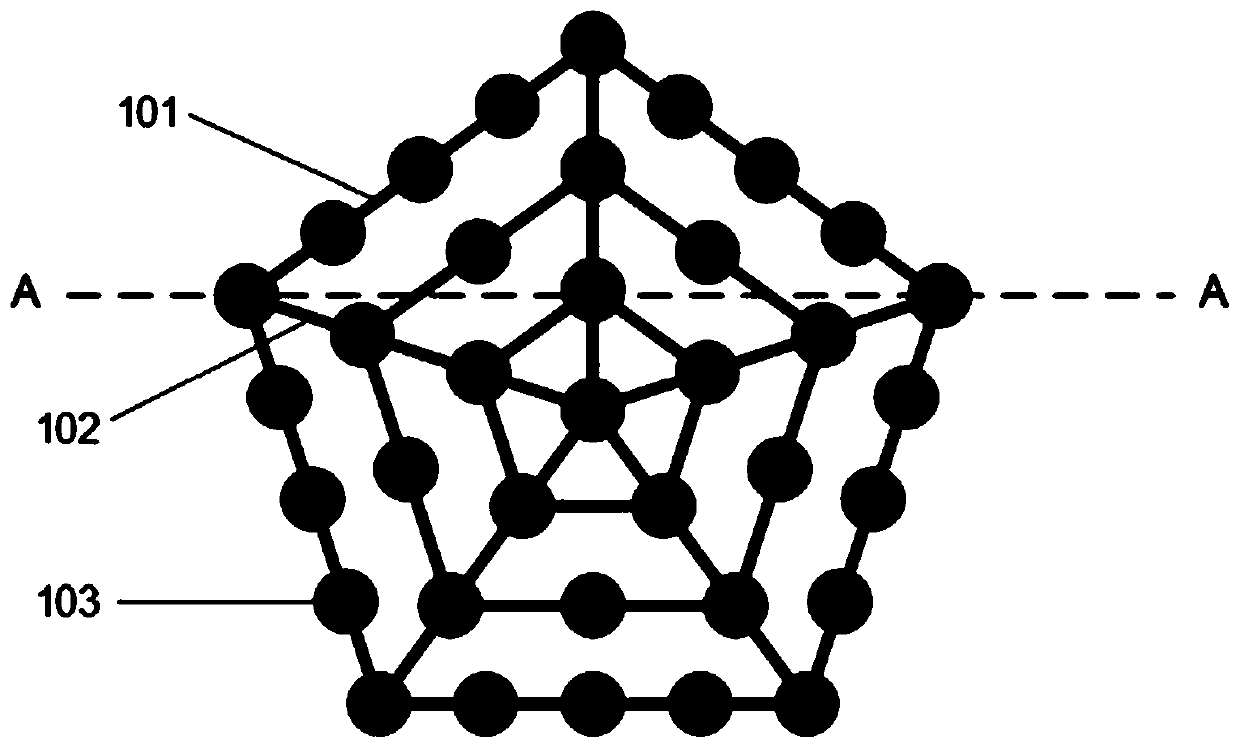

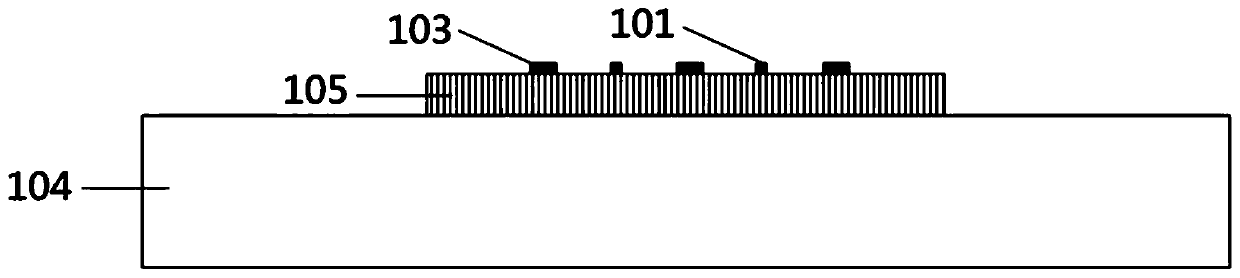

[0056] a first part comprising one or more annular segments, the center of which coincides with the center of the effective resonance region of the bulk acoustic wave resonator;

[0057] a second portion comprising a plurality of strip segments radially distributed within and / or outside of said first portion; and

[0058] The third part is located on the first part and / or on the second part, and the third part is different from the first part and the second par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com