Direct contact type hygrostat based on compressor frequency control and method thereof

A technology of frequency conversion control and constant humidity device, which is applied in heating and ventilation control systems, applications, refrigerators, etc., can solve the problems of high control difficulty, difficult to achieve precise humidity control, and the system is prone to failures, and achieves compact structure and high efficiency. Effect of dehumidification/humidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

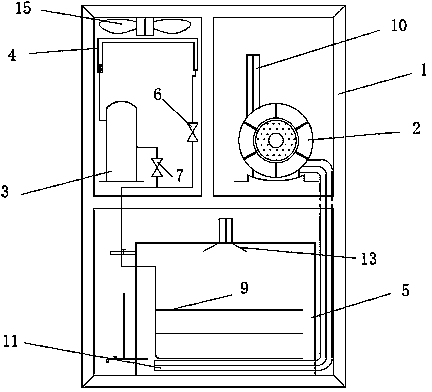

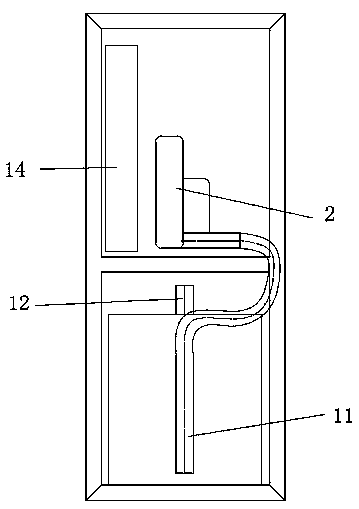

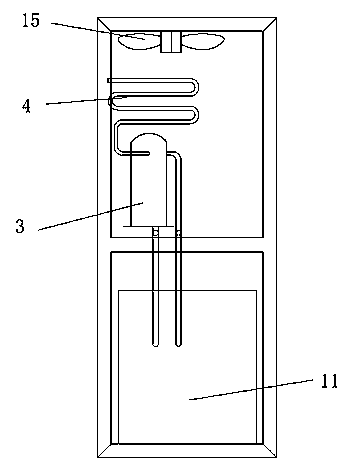

[0013] Such as figure 1 As shown, the direct contact constant humidity device adopting frequency conversion control of compressor includes cabinet 1, fan 2, compressor 3, condenser 4, water tank 5, throttle valve 6, electromagnetic reversing valve 7, frequency converter 8, evaporation 9; the compressor 3, condenser 4, electromagnetic reversing valve 7, throttle valve 6, and evaporator 9 are connected in sequence, the evaporator 9 is placed in the water tank 5, and the air inlet of the fan 2 passes through the fresh air pipe 10 and External communication, fan 2 air outlets are connected with nozzle pipe 11, nozzle pipe 11 is inserted into water tank 5 bottoms by water tank 5 right sides, water tank 5 tops are provided with deflector 13, and top air outlet is provided with air supply pipe 12.

[0014] The surface of the nozzle 11 has small holes. The speed of the compressor 3 is controlled by a frequency converter 8 , and the input end of the frequency converter 8 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com