Auxiliary agent of formulation for dyeing Terylene

A technology of auxiliaries and formulations, which is applied in the field of one-dose auxiliaries for polyester dyeing, can solve the problems of dyeing defects, unstable pH value, inconvenient use, etc., and achieve the effect of improving dyeing quality, good dyeing quality and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The formula of the auxiliary agent is composed by weight:

[0074] Citric acid 15%

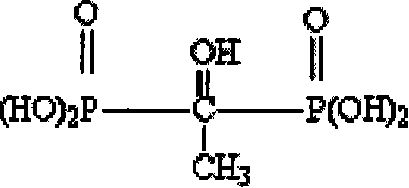

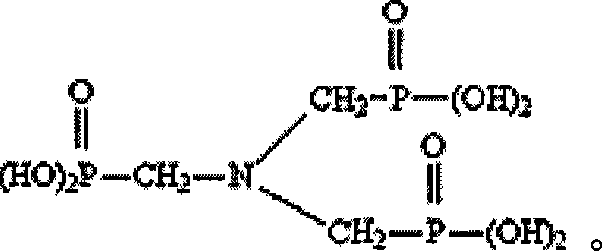

[0075] Amino trimethylene phosphonic acid 3%

[0076] Polyacrylic acid (molecular weight 60,000~70,000) 3%

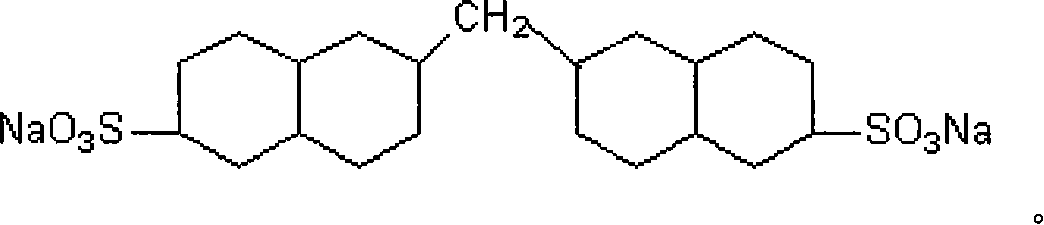

[0077] NNO 15%

[0078] Polyethylene glycol 400 monooleate 6%

[0079] Non-ionic polyacrylamide (molecular weight 7-8 million) 1%

[0080] Polyoxyethylene terephthalate (molecular weight 7000~8000) 2%

[0081] Water 55%.

[0082] Preparation:

[0083] Add appropriate amount of water, add all the materials in order by weight percentage under stirring at 40~50℃ and mix for 2~3 hours, uniformly dissolve, filter and discharge.

[0084] Dyeing process steps:

[0085] Add the one-agent auxiliaries and disperse dyes of this example to the dyeing bath. Dye the polyester fabric at 50°C, heat up to 130°C at a rate of 1°C every 2-3 minutes, keep it warm for 45-60 minutes, and then slowly cool down and release the foot water , And then reduce and clean with sodium dithionite and caustic soda for...

Embodiment 2

[0143] The formula of the auxiliary agent is composed by weight:

[0144] Hydrolyzed polymaleic anhydride (molecular weight 400~800) 20%

[0145] Hydroxyethylene diphosphonic acid 5%

[0146] Polyacrylic acid (molecular weight 60,000~70,000) 7%

[0147] NNO 16%

[0148] Polyethylene glycol (400) monooleate 8%

[0149] Non-ionic polyacrylamide (molecular weight 7-8 million) 2%

[0150] Polyoxyethylene terephthalate (molecular weight 7000~8000) 2%

[0151] Water 40%

[0152] Preparation:

[0153] Add appropriate amount of water, add all the materials in order by weight percentage under stirring at 40~50℃ and mix for 2~3 hours, uniformly dissolve, filter and discharge.

[0154] Dyeing process steps:

[0155] Add the one-agent auxiliaries and disperse dyes of the present invention to the dyeing bath, and dye polyester fabric at 50°C. The temperature is raised to 130°C at a rate of 1°C every 2-3 minutes, and the temperature is kept for 45-60 minutes, and then the temperature is slowly ...

Embodiment 3

[0166] The formula of the auxiliary agent is composed by weight:

[0167] Hydrolyzed polymaleic anhydride (molecular weight 400~800) 20%

[0168] Hydroxyethylene diphosphonic acid 5%

[0169] Polyacrylic acid (molecular weight 60,000~70,000) 7%

[0170] NNO 18%

[0171] Polyethylene glycol (400) monooleate 8%

[0172] Water 42%

[0173] Preparation:

[0174] Add appropriate amount of water, add all the materials in order by weight percentage under stirring at 40~50℃ and mix for 2~3 hours, uniformly dissolve, filter and discharge.

[0175] Dyeing process steps:

[0176] Add the one-agent auxiliaries and disperse dyes of the present invention to the dyeing bath, and dye polyester fabric at 50°C. The temperature is raised to 130°C at a rate of 1°C every 2-3 minutes, and the temperature is kept for 45-60 minutes, and then the temperature is slowly dropped. Reducing and cleaning with sodium dithionite and caustic soda at 85°C for 15 minutes, put in foot water, and then rinse with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com