Strip steel electrolysis descaling process and device

A descaling device and technology for strip steel, applied in the electrolysis process, electrolysis components, manufacturing tools, etc., can solve the problems that affect the surface quality and processing performance of cold-rolled sheets, the descaling method is not popularized, and the service life of the emulsion is shortened. problems, to achieve the effect of eliminating or environmental pollution, low maintenance cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

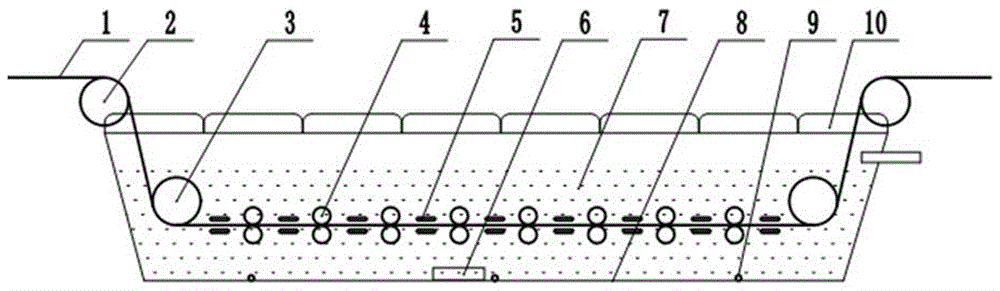

[0045] Embodiment 1: the strip steel electrolytic descaling process comprises the following steps:

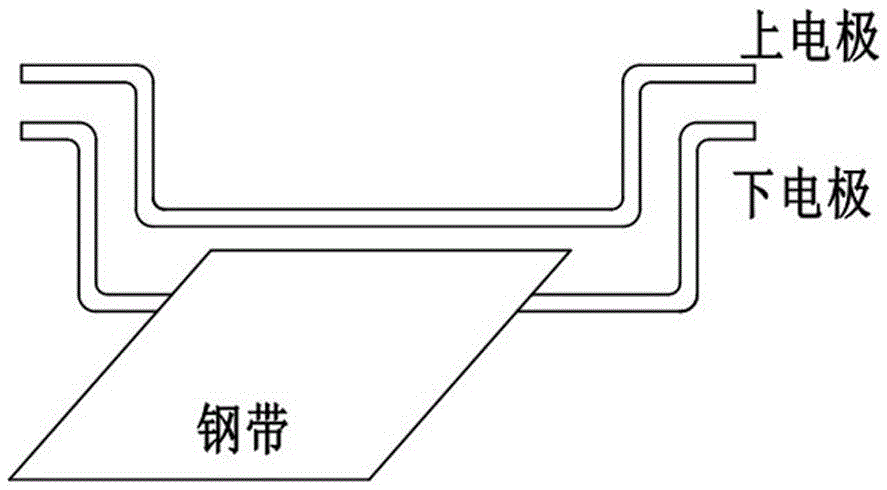

[0046] Electrolysis: the electrolytic cell is filled with a neutral electrolyte Na 2 S0 4 solution, the electrolyte is adjusted in the pH range of 4 to 7.0, several pairs of electrodes are arranged in the electrolytic cell, each pair of electrodes has the same polarity, each pair is arranged up and down, and the strip passes through between each pair of electrodes, and the plurality of pairs of electrodes Alternate arrangement of cathode and anode. The strip itself is not charged. When the polarity of the opposite electrode is anode, the strip is the opposite cathode. When the polarity of the opposite electrode is cathode, the strip is the opposite anode. The last pair of electrodes at the strip end is the cathode, and the steel strip is the opposite anode for electrolytic descaling; the electrode plates are made of silicon cast iron. The number of pairs of electrodes is arr...

Embodiment 2

[0048] Example 2: Several pairs of electrodes are arranged in a group of 4 pairs, each group has the same polarity, and the cathode and anode are alternately arranged between groups. All the other are with embodiment 1.

Embodiment 3

[0049] Embodiment 3: In the strip steel electrolytic descaling process, step (1) is the same as in embodiment 1, including step (2) cleaning and step (3) drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com