Glue mixing apparatus

A technology of mixing device and glue, applied in mixer, dissolving, chemical instruments and methods, etc., can solve the problems of inconvenient operation and complex structure, and achieve the effects of convenient cleaning, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

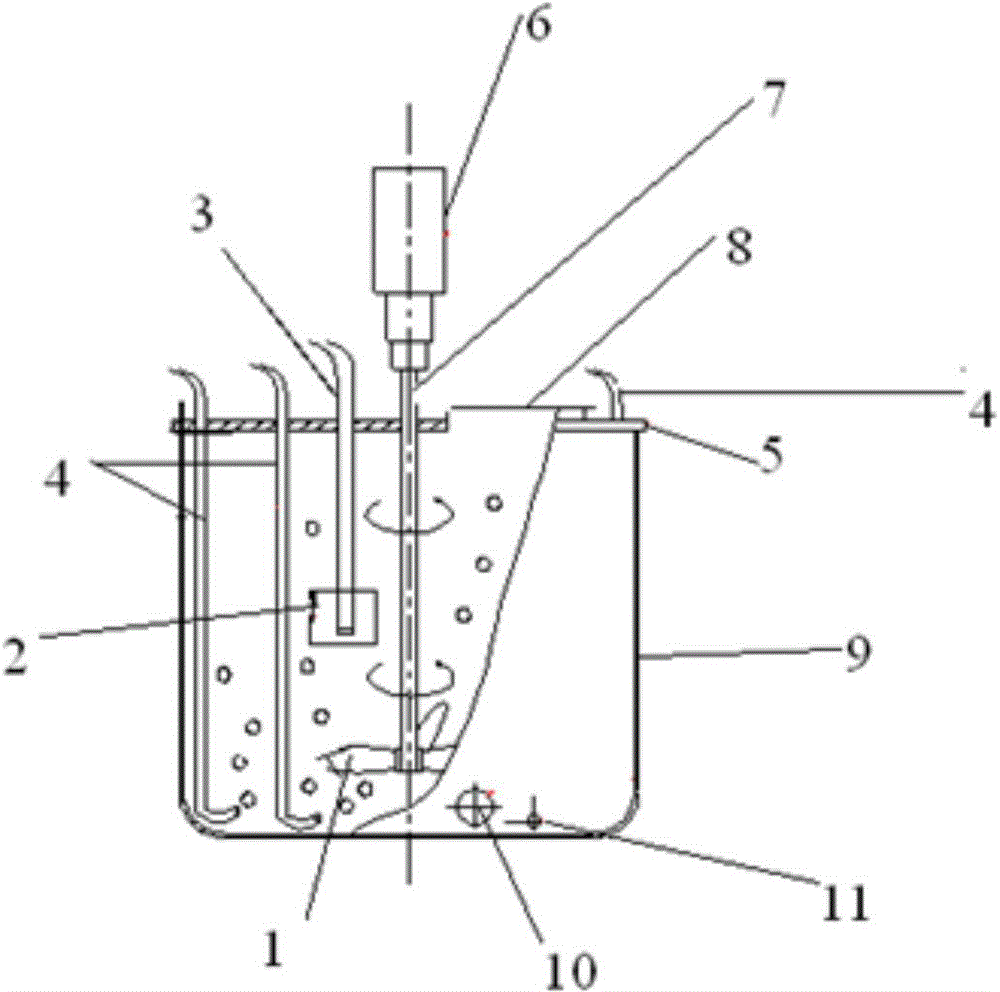

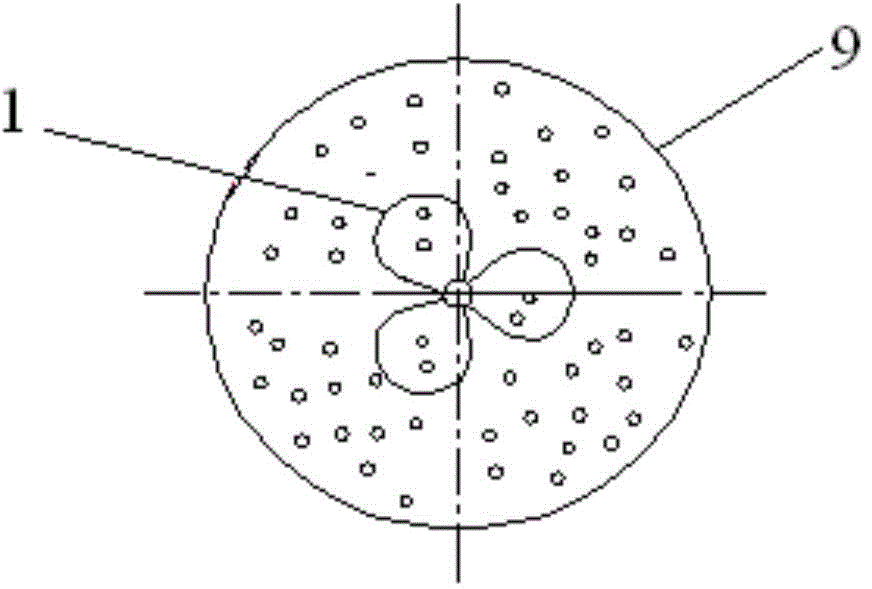

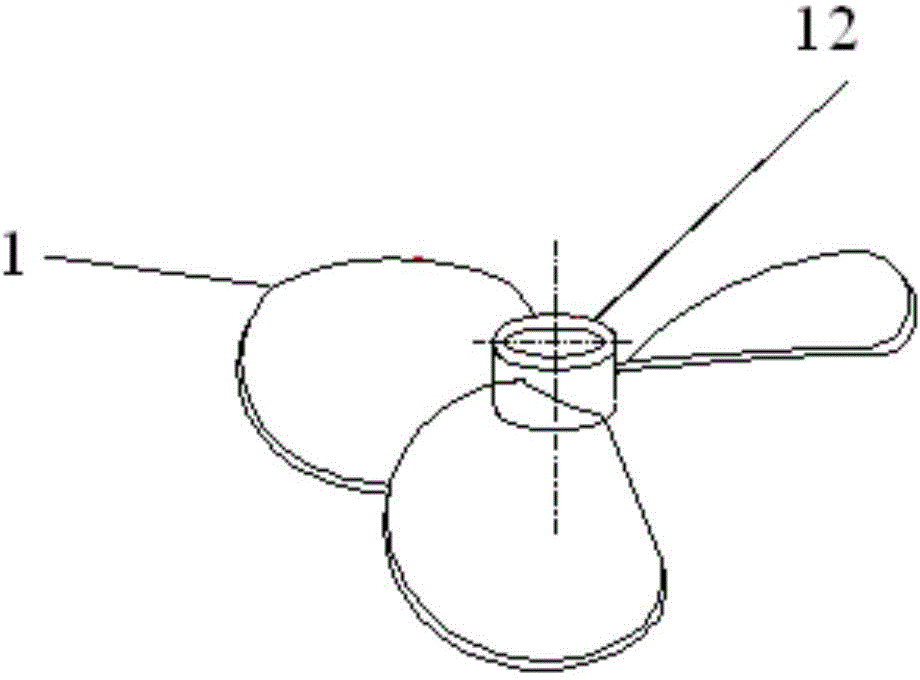

[0026] like figure 1 and image 3 As shown, a glue mixing device includes a glue mixing tank, a uniform power device, an inflation device and a return device 2 . The glue mixing tank includes a tank body 9 and a tank cover 5 that is sealed at the opening of the tank body 9. The tank body 9 is engraved with a scale, and the dilution ratio can be directly controlled by watching the liquid level height. The bottom of the tank body 9 is provided with The discharge port 10 and the sewage discharge port 11, the sewage discharge port 11 is arranged diagonally below the discharge port, the tank cover 5 is made of PVC material, and the tank cover 5 is provided with a feeding port 8, and the raw glue and water are in proportion according to the requirements of the process This is added to the tank. The uniform power device includes a motor 6, a stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com