Press section of a machine for producing a fibrous web

A press section, fiber web technology, applied in the press section, paper machine, papermaking, etc., can solve problems such as limitation and optimization, and achieve the effect of reducing moisture return, high dehydration rate, and high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

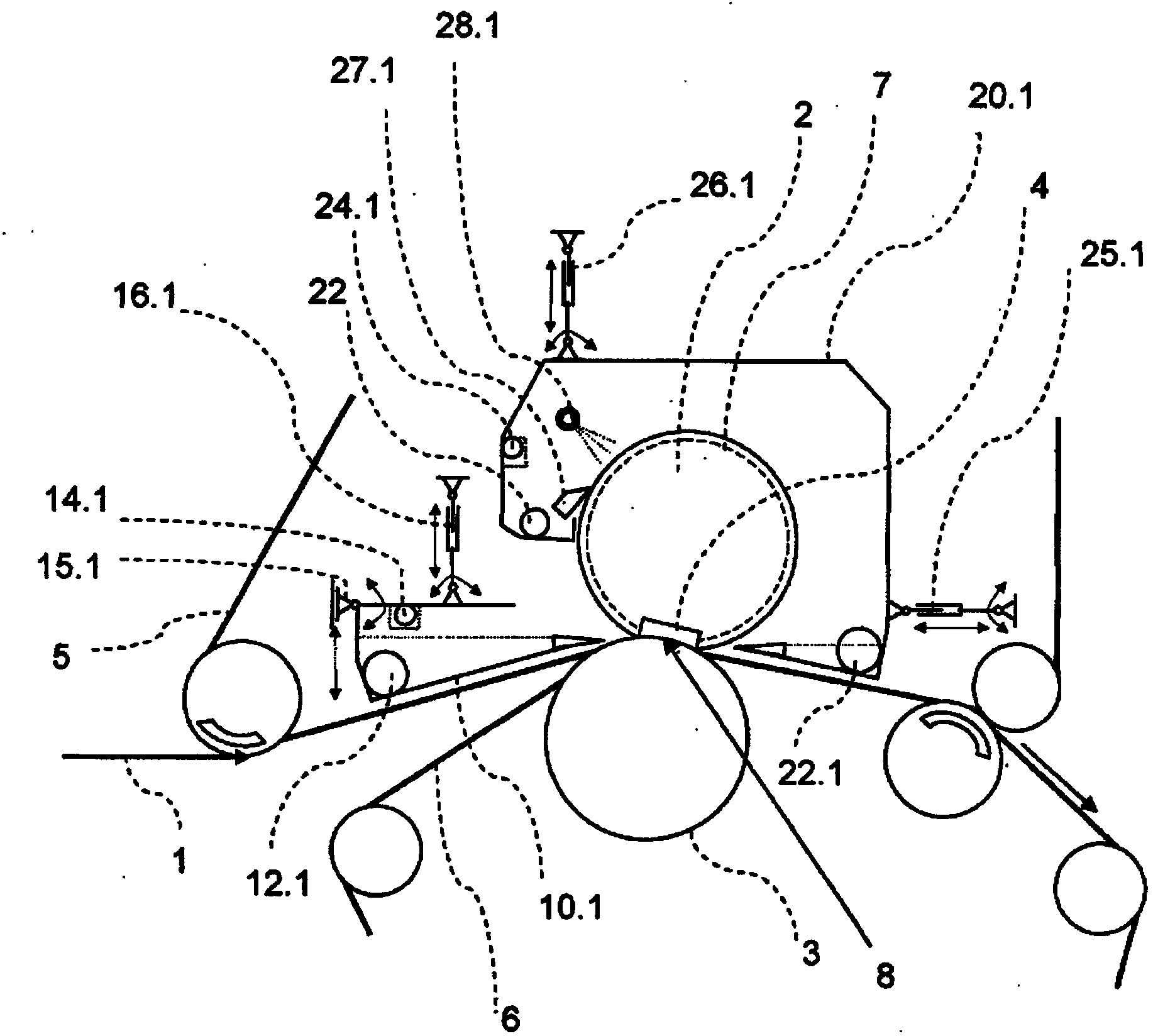

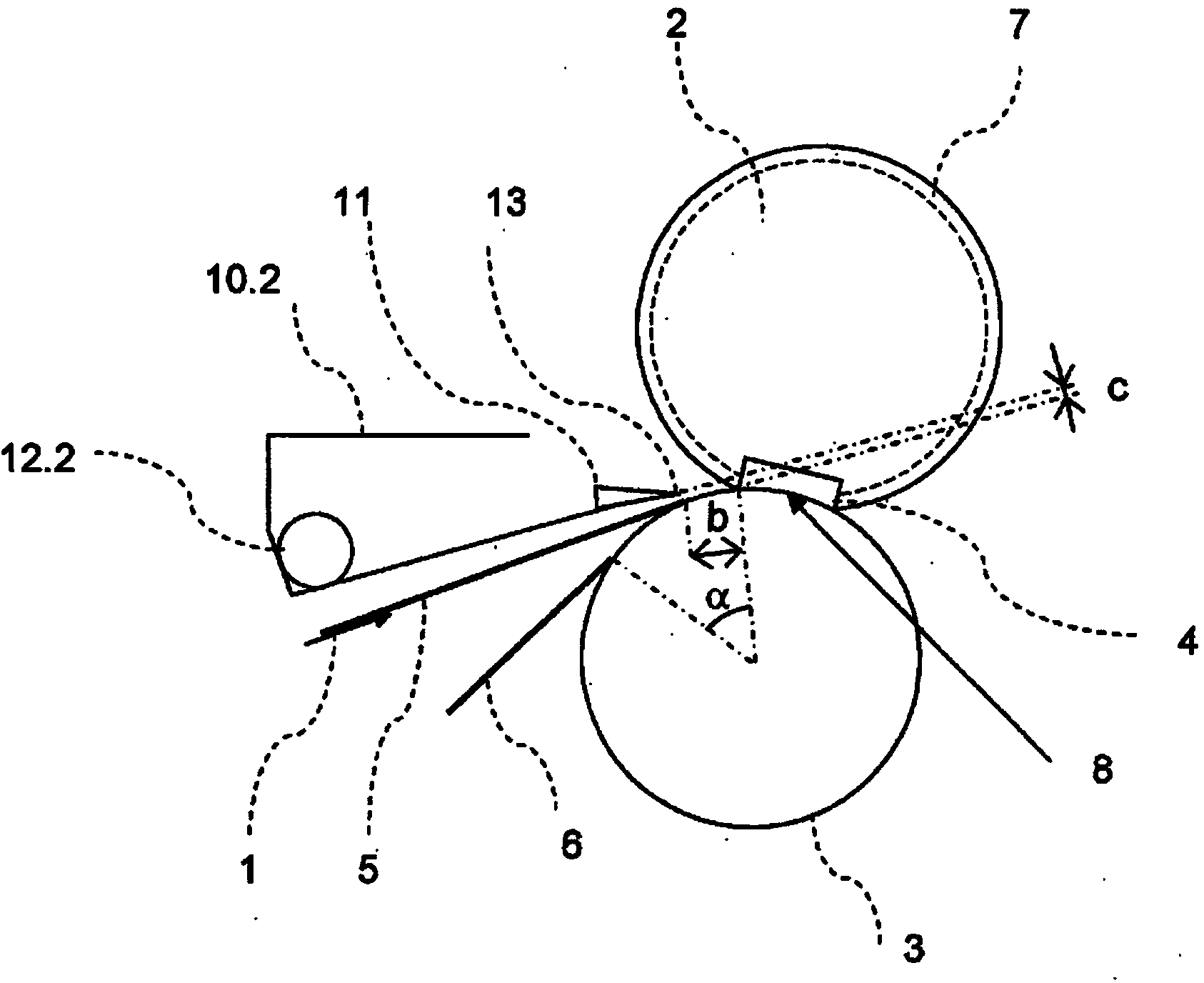

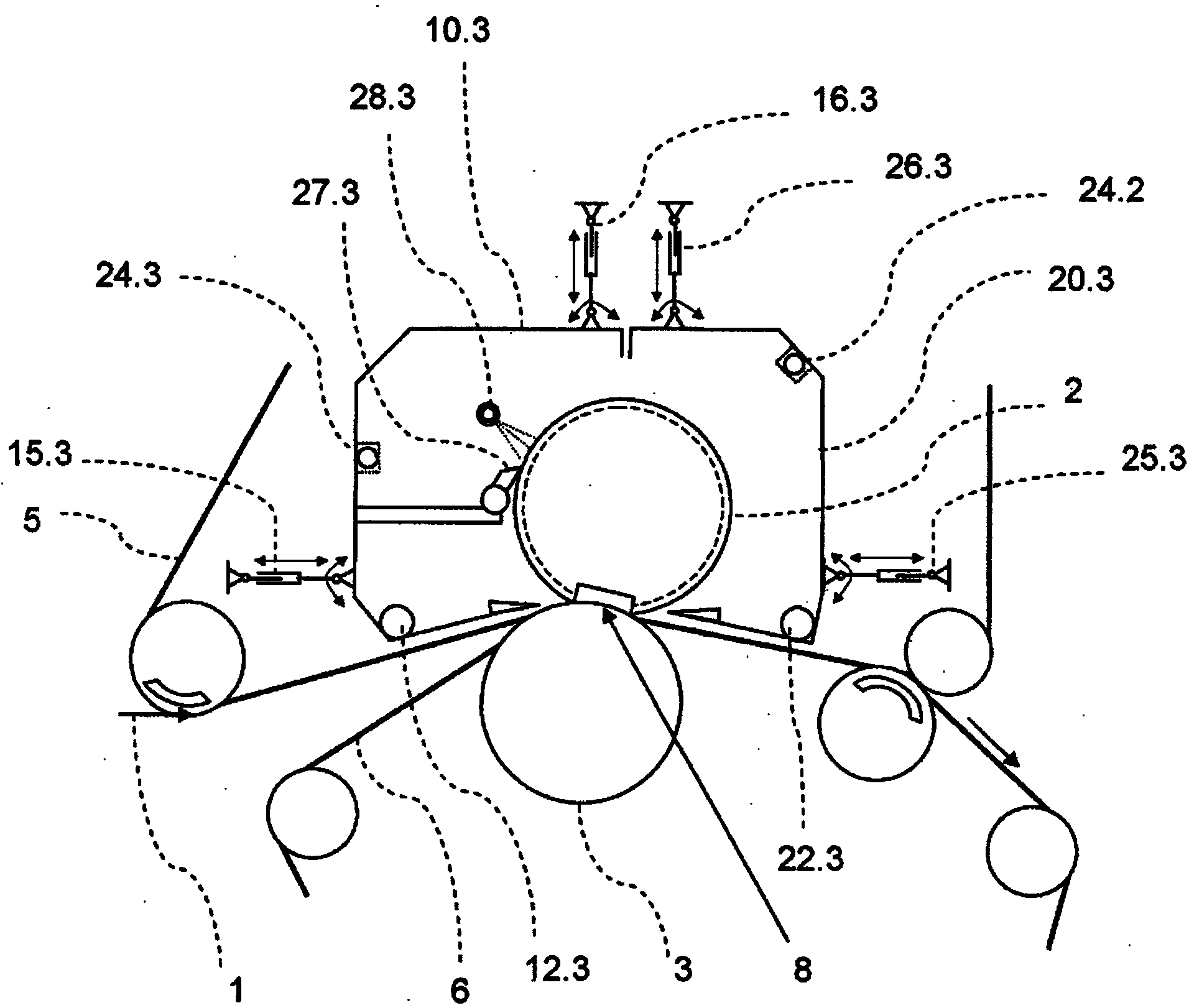

[0045] The drawings are described in detail below.

[0046] on the basis of figure 1 In the configuration of 10000, the shoe press nip 8 is formed by the press roll 2 located above and the counter roll 3 located below. The press element 4 shown here only in one piece is pressed against the jacket from the inside by means of a press element not shown, and thus produces an extended press nip. The fibrous web 1 is run through and dewatered at the press nip together with the first felt 5 and the second felt 6 . Due to the special configuration of the grooved jacket of the press roll 2, the water that has been pressed out at the beginning and sprayed back against the direction of web travel is collected in the collecting tank 10.1 and discharged through the outlet 12.1. Possible sprays are sucked by means of the suction 14.1. The collecting trough is pivotable and adjustable by means of adjustment means 15.1 and 16.1. As a result, a precise orientation of the injection or intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com