Interlayer bonding agent for spraying spray polyurea waterproof coating and preparation method thereof

A waterproof coating and adhesive technology, applied in the field of adhesive materials, can solve the problems of harmful production and construction workers' health, inaccurate construction site ratio, failure to reach the bond strength between layers, etc. Cost, reduce cost, improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

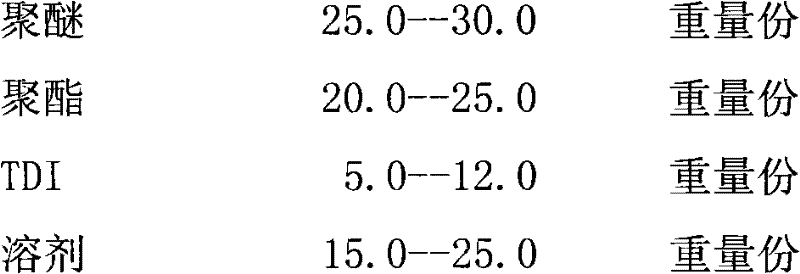

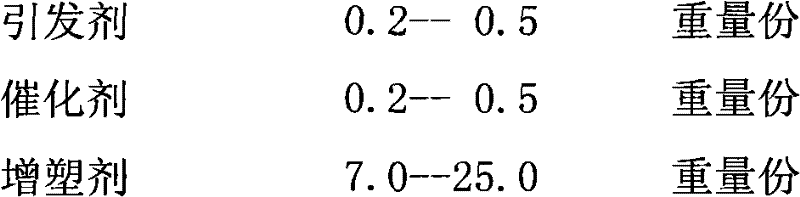

[0065] A.Product formula

[0066]

[0067]

[0068] B. Preparation method

[0069] 1). Accurately weigh the entire weight of polyethylene terephthalate, polyethylene glycol ether 2000, dioctyl phthalate and dibutyl phthalate according to the formula, add it to the reaction kettle, and start the mixer , and heat up to 100--130°C;

[0070] 2). At the above temperature, turn on the vacuum pump to evacuate, stir and dehydrate for 2 hours, and keep the vacuum degree below -0.085MPa;

[0071] 3). Turn off the heating power supply or steam valve, stop heating, and put cooling water into the jacket of the reaction kettle to lower the temperature in the kettle to below 70°C;

[0072] 4). Accurately weigh the entire weight of toluene diisocyanate and benzoyl chloride according to the formula, add them to the reaction kettle, control the temperature between 70-80°C, and keep the temperature for 2 hours;

[0073] 5). After reaching the time, cool down to 70°C, weigh acetone and a...

Embodiment 2

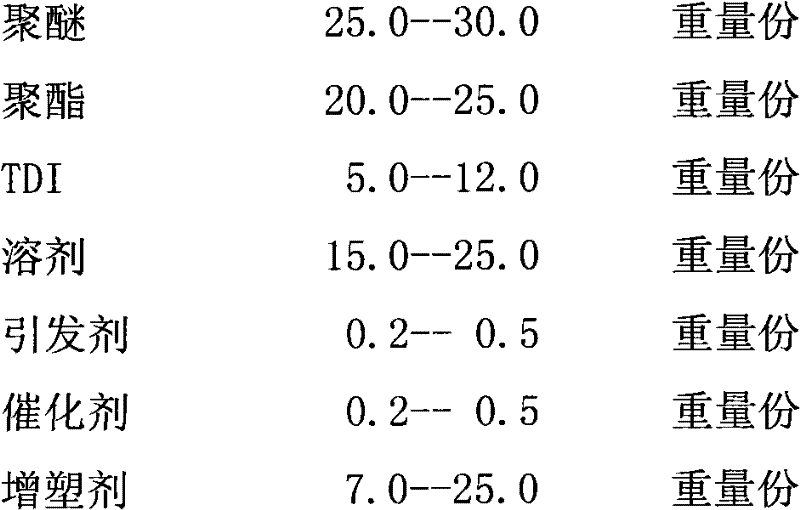

[0077] A.Product formula

[0078]

[0079]

[0080] B. Preparation method

[0081] 1). Accurately weigh the entire weight of polybutylene terephthalate, polyethylene glycol ether 3050, dibutyl phthalate and dioctyl phthalate according to the formula, add it to the reaction kettle, and start the mixer , and heat up to 100--130°C;

[0082] 2). At the above temperature, turn on the vacuum pump to evacuate, stir and dehydrate for 2 hours, and keep the vacuum degree below -0.085MPa;

[0083] 3). Turn off the heating power supply or steam valve, stop heating, and put cooling water into the jacket of the reaction kettle to lower the temperature in the kettle to below 70°C;

[0084] 4). Accurately weigh the entire weight of diphenylmethane diisocyanate and benzoyl chloride according to the formula, add it to the reaction kettle, control the temperature between 70-80°C, and keep it warm for 2 hours;

[0085] 5). After reaching the time, cool down to 70°C, weigh solvent oil and...

Embodiment 3

[0089] A.Product formula

[0090]

[0091] B. Preparation method

[0092] 1). Accurately weigh the entire weight of polydiallyl terephthalate, polyethylene glycol ether 2000, dioctyl phthalate and dibutyl phthalate according to the formula, add it to the reaction kettle, and start the mixer , and heat up to 100--130°C;

[0093] 2). At the above temperature, turn on the vacuum pump to evacuate, stir and dehydrate for 2 hours, and keep the vacuum degree below -0.085MPa;

[0094] 3). Turn off the heating power supply or steam valve, stop heating, and put cooling water into the jacket of the reaction kettle to lower the temperature in the kettle to below 70°C;

[0095] 4). Accurately weigh the entire weight of toluene diisocyanate and benzoyl chloride according to the formula, add them to the reaction kettle, control the temperature between 70-80°C, and keep the temperature for 2 hours;

[0096] 5). After reaching the time, cool down to 70°C, weigh acetone and add it to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com