Intelligent Wi-Fi sound box automatic production test system and method

A technology of production testing and wi-fi, applied in the direction of electrical components, etc., can solve problems such as high requirements for testers' professional ability, increased labor costs, and difficulty in ensuring uniform testing standards, so as to reduce the space for discretion and professional knowledge Requirements, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

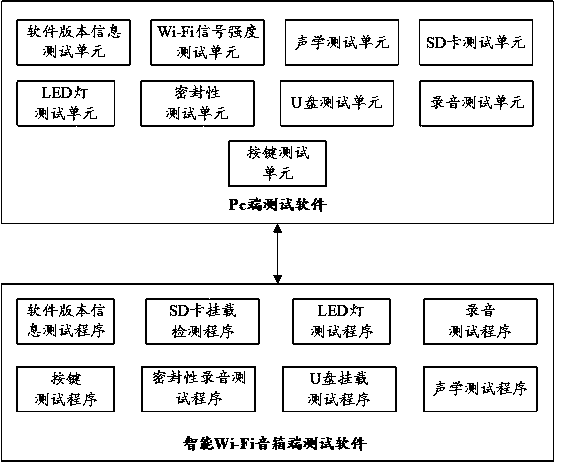

[0023] as attached figure 1 Shown, a kind of intelligent Wi-Fi speaker automatic production testing system, comprises PC, intelligent Wi-Fi speaker and scanning gun; Described Pc is installed with Pc end test software; Described intelligent Wi-Fi speaker is installed with speaker end test software ;

[0024] PC-side test software includes software version information test unit, Wi-Fi signal strength test unit, acoustic test unit, SD card test unit, LED light test unit, airtightness test unit, U disk test unit, recording test unit, button test unit ;

[0025] Speaker test software includes software version information test program, acoustic test program, LED lamp test program, U disk mount test program, recording test program, SD card mount test program, airtightness test program, button test program;

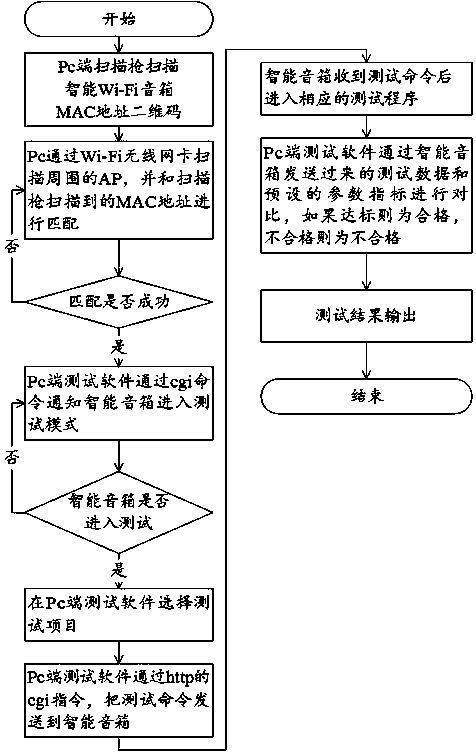

[0026] When the smart Wi-Fi speaker is tested, the tester opens the test software and the http client program on the PC, scans the QR code of the MAC address of the smart Wi-F...

Embodiment 2

[0028] as attached figure 2 As shown, a kind of intelligent Wi-Fi speaker automatic production test method based on the intelligent Wi-Fi speaker automatic production test system comprises the following steps:

[0029] Step 1. When testing the software version information, the software version information testing unit pushes it to the smart Wi-Fi speaker through the cgi command, and the software version information test program reads the version number of the smart Wi-Fi speaker and compares it with the preset version number; If the version numbers are the same, it is qualified, otherwise it is not qualified;

[0030] Step 2. When performing the Wi-Fi signal strength test, the Wi-Fi signal strength test unit compares the Wi-Fi signal strength reported by the driver with the preset minimum value. If it is greater than -70db, it is qualified, otherwise it is unqualified ;

[0031] Step 3. When conducting the acoustic test, the acoustic test unit pushes the test audio link to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com