Combined rock-embedding pile and its construction method

A construction method and combined pile technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of necking, cavity and sediment interlayer, severe vibration, and high technical requirements for operation, and achieve good economic benefits and quality. Guaranteed, extubation speed increase, accurate calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

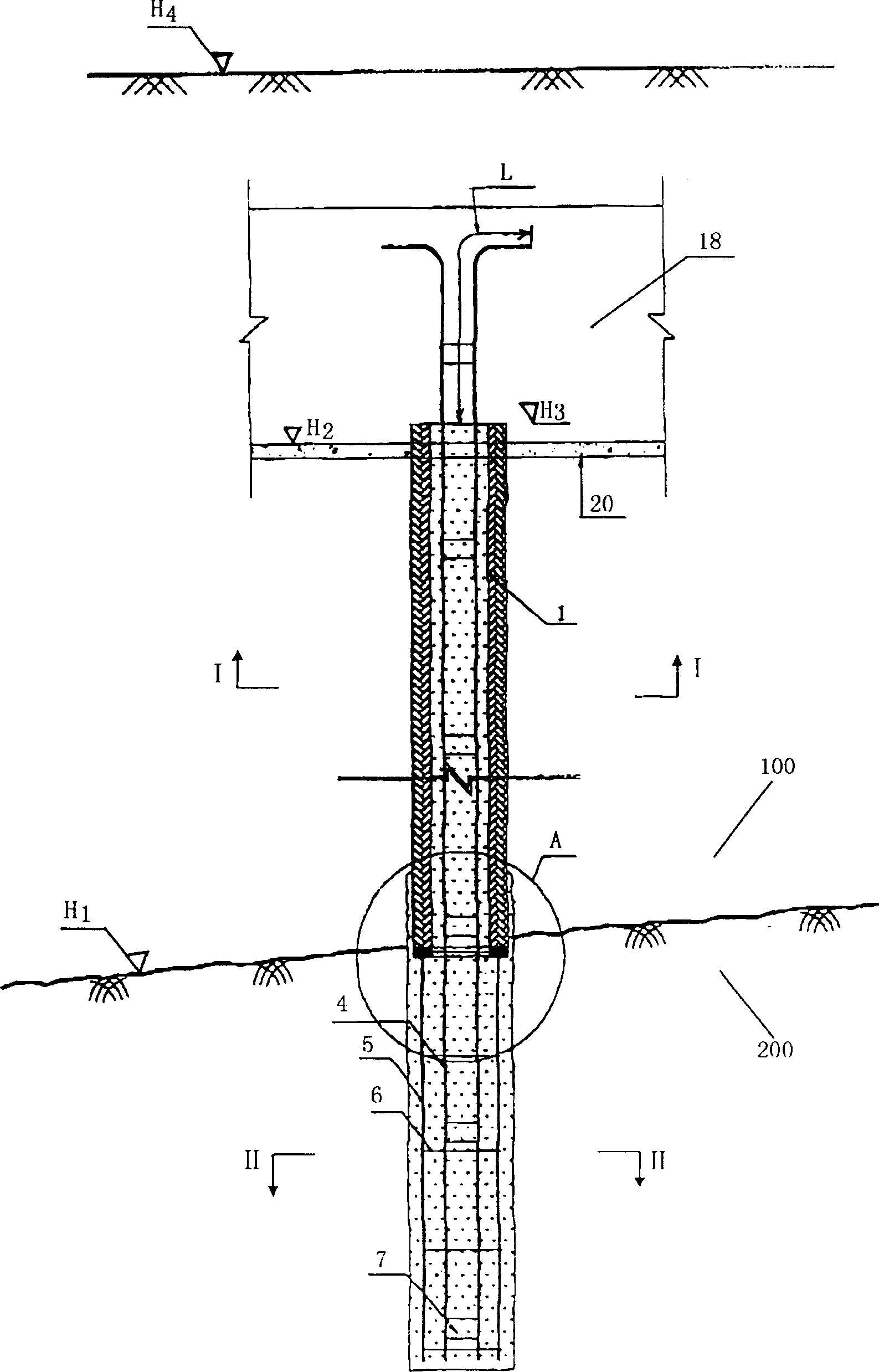

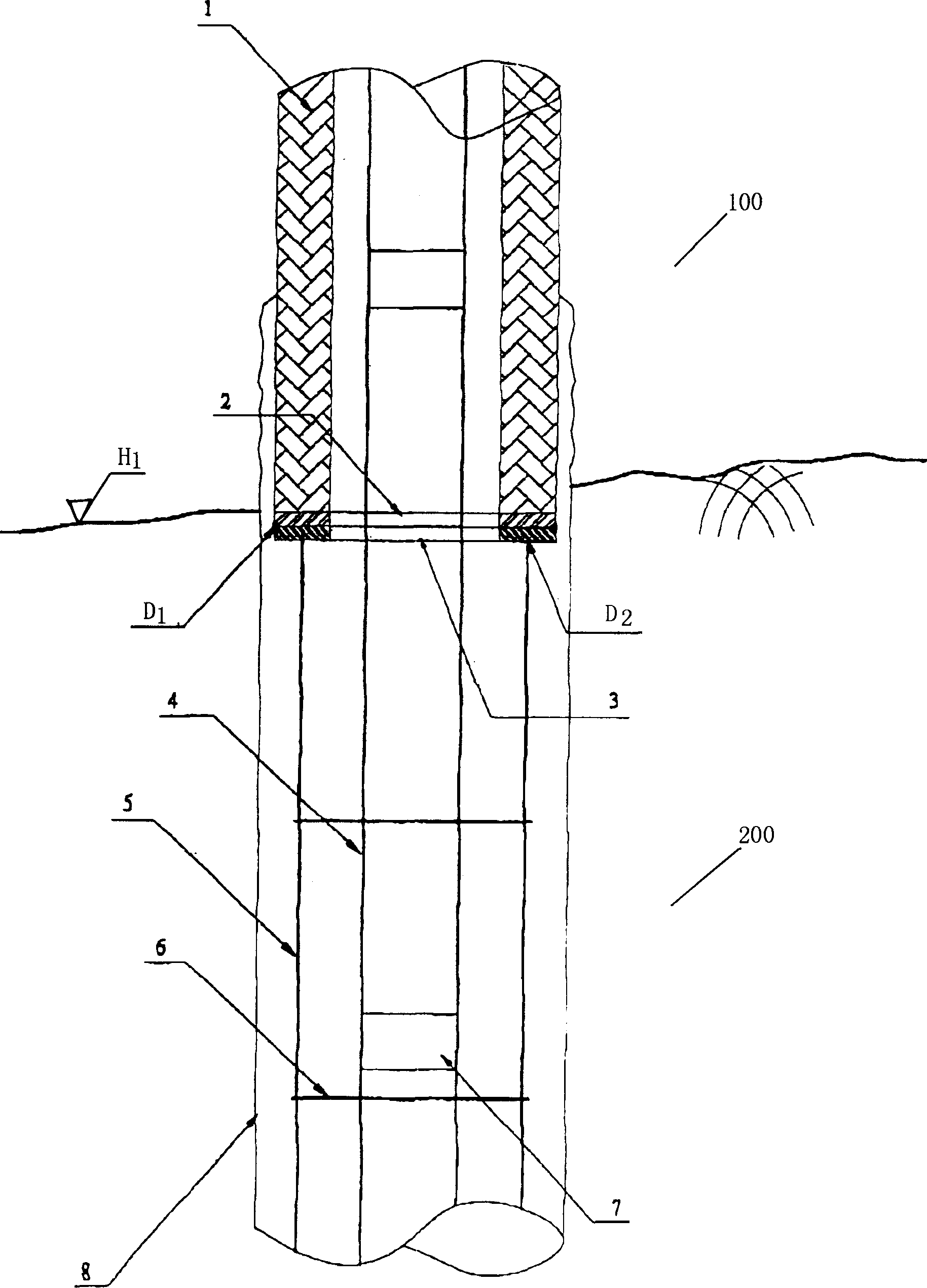

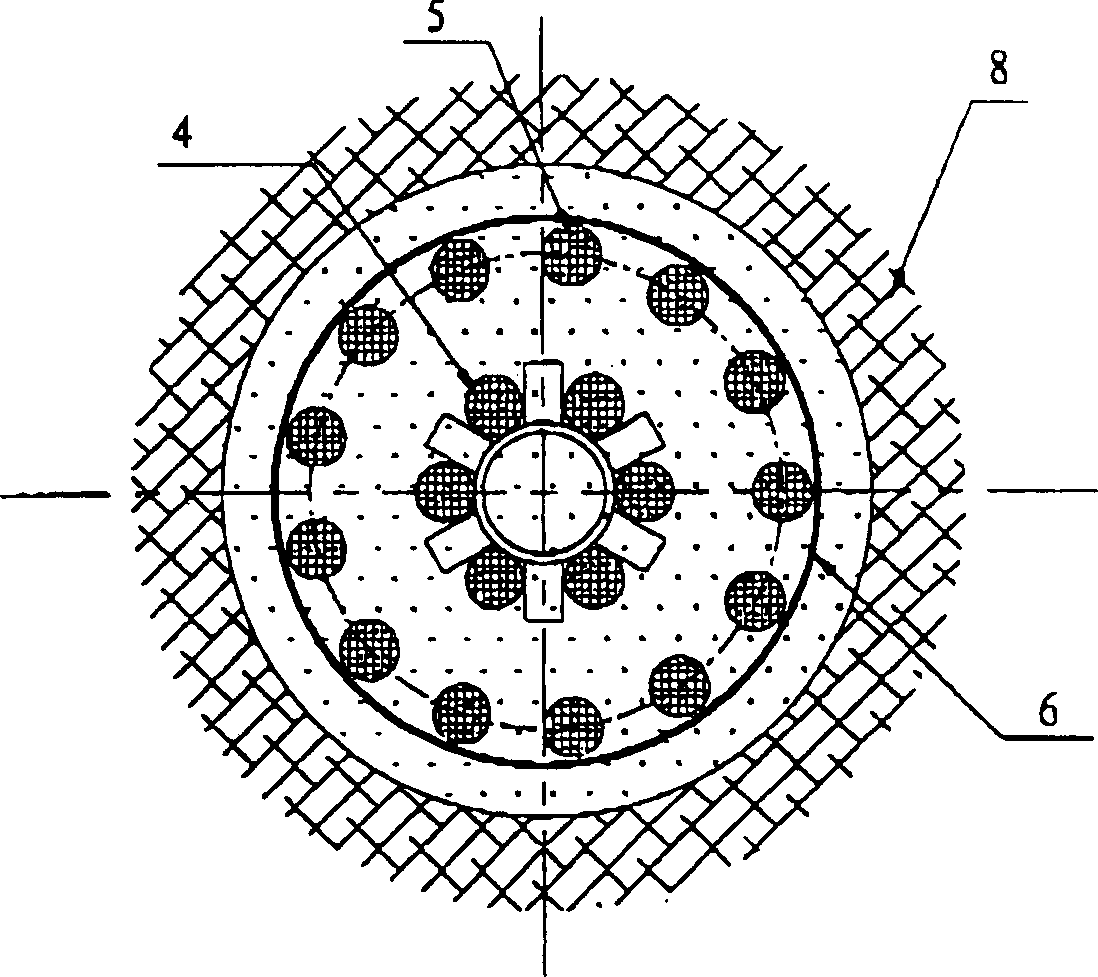

[0061] exist figure 1 with figure 2 The detailed internal structure of the first embodiment of the present invention, Type 1, is shown in . exist figure 1 Among them, the pile body is set in the soil layer 100 and the rock layer 200. According to the design requirements of the pile body, the rock top surface elevation H1, the pile cap bottom elevation H2, the pile head design elevation H4, and the construction surface ground elevation H4 are set accordingly, and Pile cap 18, cushion layer 20 and anchorage length L. There is an end plate 2 at the lower end of the concrete pipe 1, and below the end plate 2 is a reinforcement cage end plate 3, a plurality of main reinforcement bars 4 that run through the entire length of the pile body, and a plurality of reinforcement bars 5 that are only arranged in the rock hole. figure 1 , figure 2 , Figure 3, it can be seen that the distribution circle of the main reinforcement 4 is smaller than that of the reinforcement 5. The spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com