Large-span combined super-heavy eccentric slope angle steel structure overall synchronous jacking equipment

A synchronous jacking and combined technology, which is applied in the direction of lifting devices, building structures, and building materials processing, etc., can solve the problem that structural steel columns cannot meet the bearing capacity requirements, material rental and labor costs are high, and it is difficult to meet construction requirements, etc. To solve the problem, to achieve the effect of convenient welding seam inspection and rod installation position check and other quality inspection, easy to guarantee the construction quality, and reduce the effect of vertical transportation and hoisting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

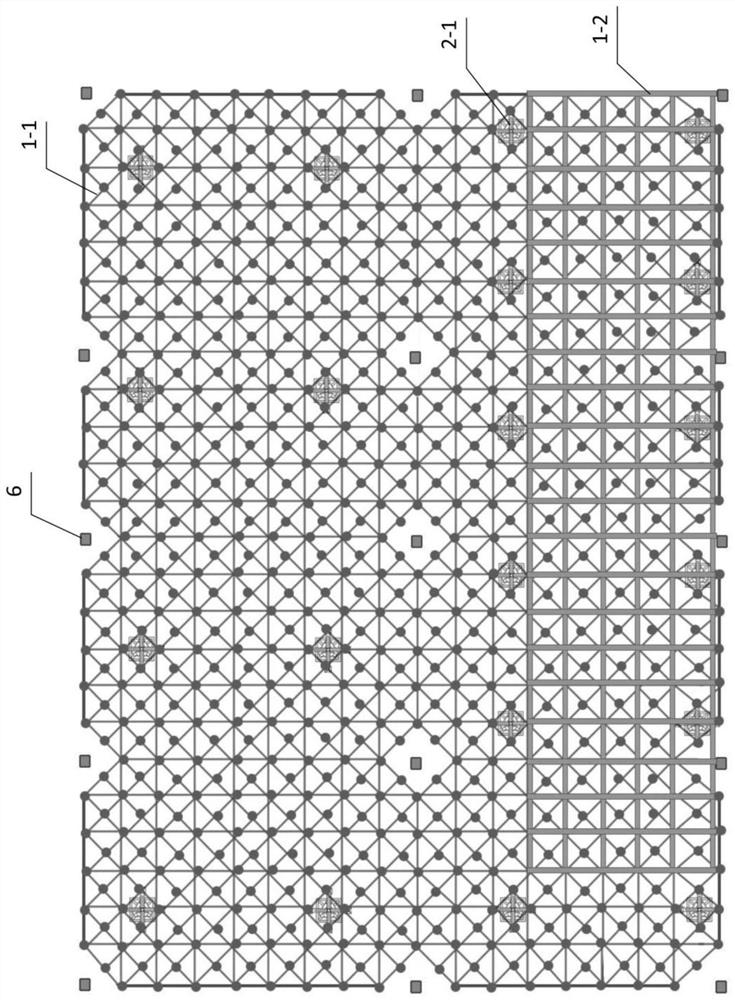

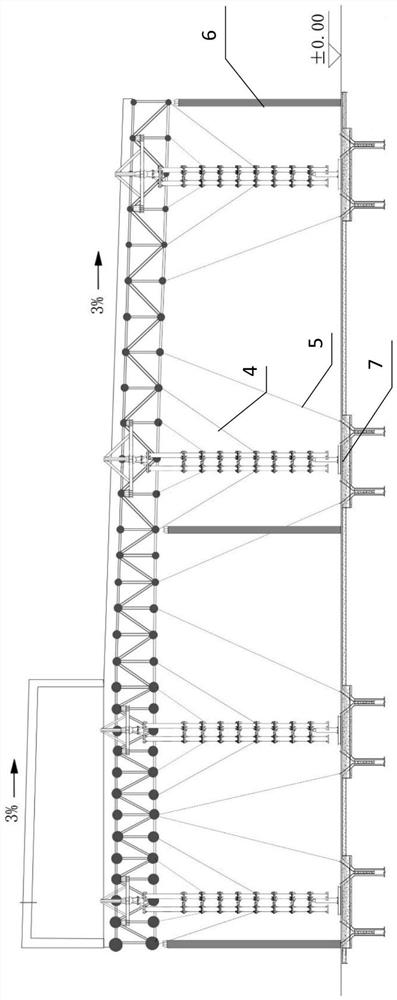

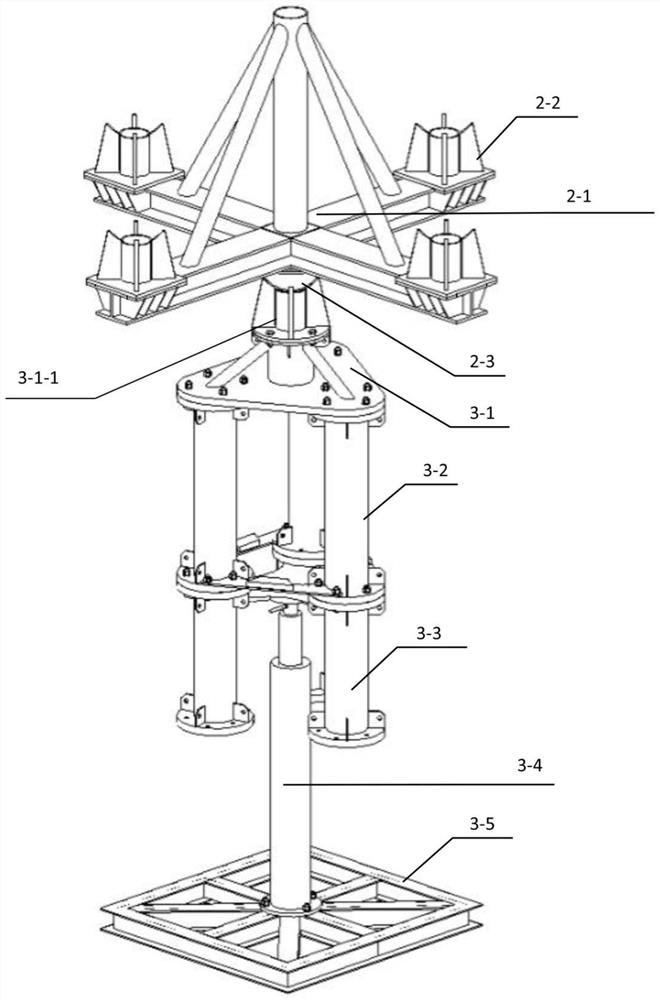

[0042] see Figure 1 to Figure 14 , a large-span combined super-heavy eccentric slope angle steel structure overall synchronous jacking equipment, including a plurality of jacking units, and a plurality of jacking units are arranged on a plurality of jacking foundations 7 in one-to-one correspondence, and the jacking units The foundation 7 is set on the floor; each of the jacking units includes a cross joist 2-1 and a jacking frame coaxially arranged sequentially from top to bottom, and the jacking frame is lifted by a jack 3-4.

[0043] The jacking frame includes a jacking bracket 3-1, an initial section 3-2, a multi-level standard section 3-3 and a base 3-5 arranged coaxially in sequence from top to bottom.

[0044] The initial section 3-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com