Construction method of overall synchronous jacking up of large-span combined super-heavy eccentric slope angle steel structure

A technology of simultaneous jacking and steel structure, applied in the direction of lifting frame, lifting device, building structure, etc., can solve the problems that structural steel columns cannot meet the bearing capacity requirements, material rental and labor costs are high, and it is difficult to meet construction requirements, etc. To achieve the effect of easy guarantee of construction quality, reduction of vertical transportation and hoisting operations, and beneficial to construction cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

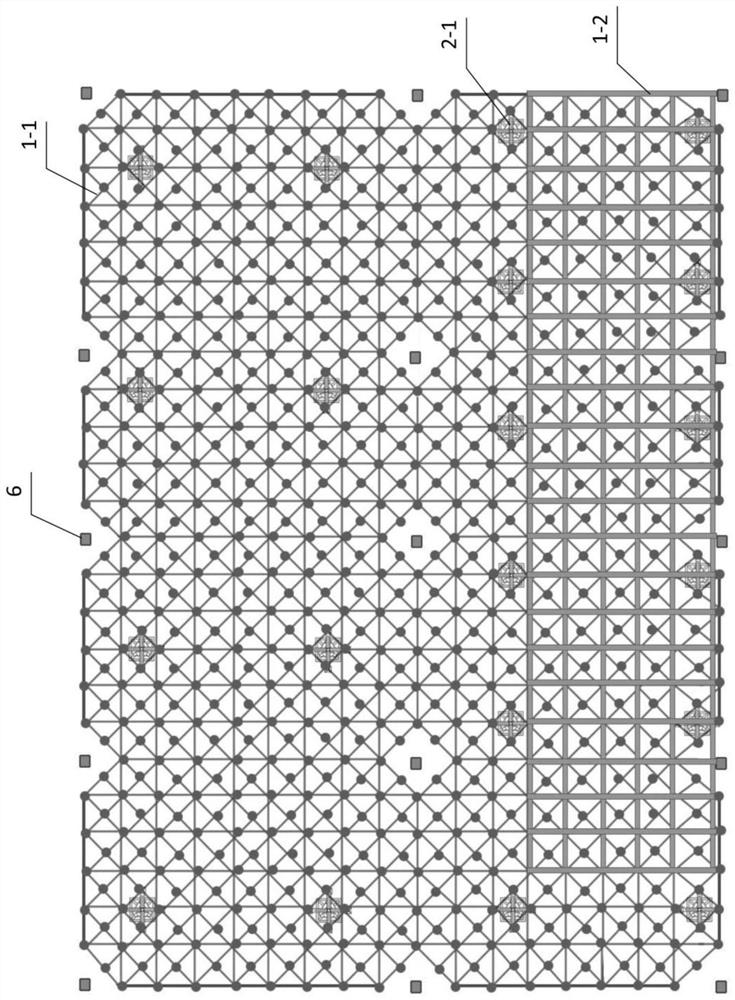

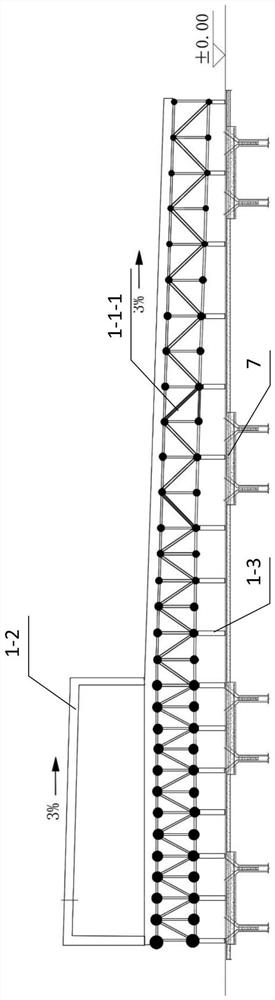

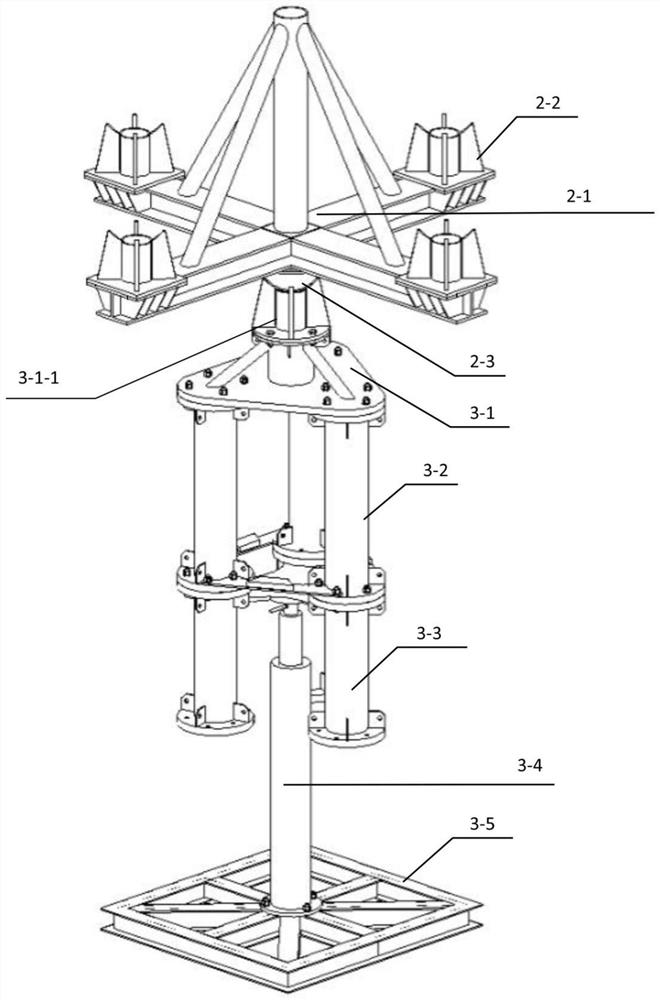

[0050] see Figure 1 to Figure 11 , a large-span combined overweight eccentric slope angle steel structure overall synchronous jacking construction method, the following steps are adopted:

[0051] 1) Construct a corresponding number of jacking foundations 7 on the floor according to the set multiple jacking points.

[0052] 2) After the floor is hardened, the ground assembly and acceptance of the combined steel structure is carried out. When assembling the steel structure, use multi-point support piers 1-3 leveled along the slope of the grid to support the lower string ball of the grid, and replace the more stressed rods in the grid according to the lifting force of the grid Become a permanent structural reinforcement member 1-1-1.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com