Electric slag pressure welding appearance quality measuring device and using method thereof

A technology of electroslag pressure welding and appearance quality, which is applied in measuring devices, mechanical measuring devices, angle/taper measurement, etc., and can solve problems such as low quality, welding package height, axis offset of upper and lower steel bars, and hidden safety hazards of engineering entities. , to achieve the effect of quality control and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

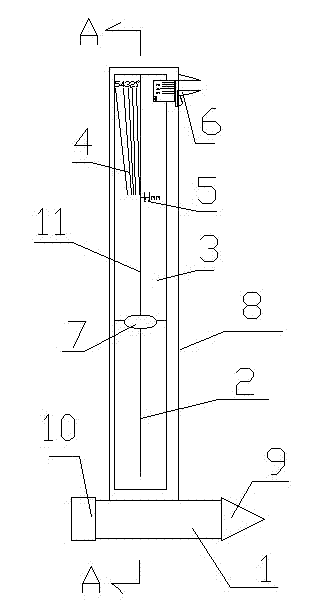

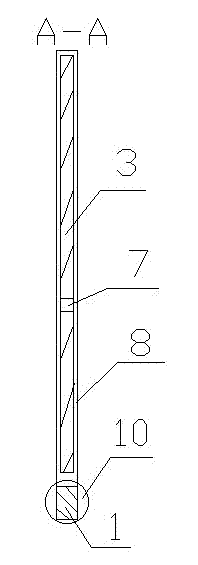

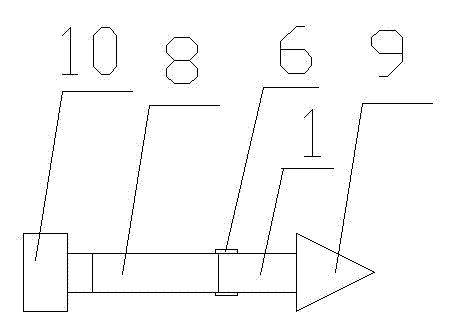

[0012] From figure 1 , 2 , 3, it can be seen that the present invention is composed of a strip-shaped measuring ruler 3 equipped with a metal frame and a hammer vertically welded to the bottom surface of the metal frame of the measuring ruler; the hammer includes a welded left end The cylinder end 10, the cone end 9 at the right end, the middle horizontal strip-shaped hammer beam 1, the thickness of the hammer beam 1 is the same as the thickness of the metal frame of the measuring ruler, and the bottom surface of the metal frame is welded on the hammer beam The top surface of the hammer; the hammer is used to remove the remaining welding slag on the welding lap during quality inspection, the cylindrical end is used for large-area welding slag treatment, and the conical end is used for the remaining welding slag on the local welding lap Processing; the measuring ruler 3 is made of a transparent plastic lens, and its middle part is provided with an oval electroslag pressure wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com