Self-locking assembly type buckling-restrained brace for nuclear island structure

An anti-buckling support and assembled technology, which is applied in the direction of earthquake resistance, building components, protective buildings/shelters, etc., can solve the problems of increasing the seismic appraisal cost of related systems, large steel platform span and support load, and reducing structural response. , to achieve the effect of convenient quality inspection, high production level and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

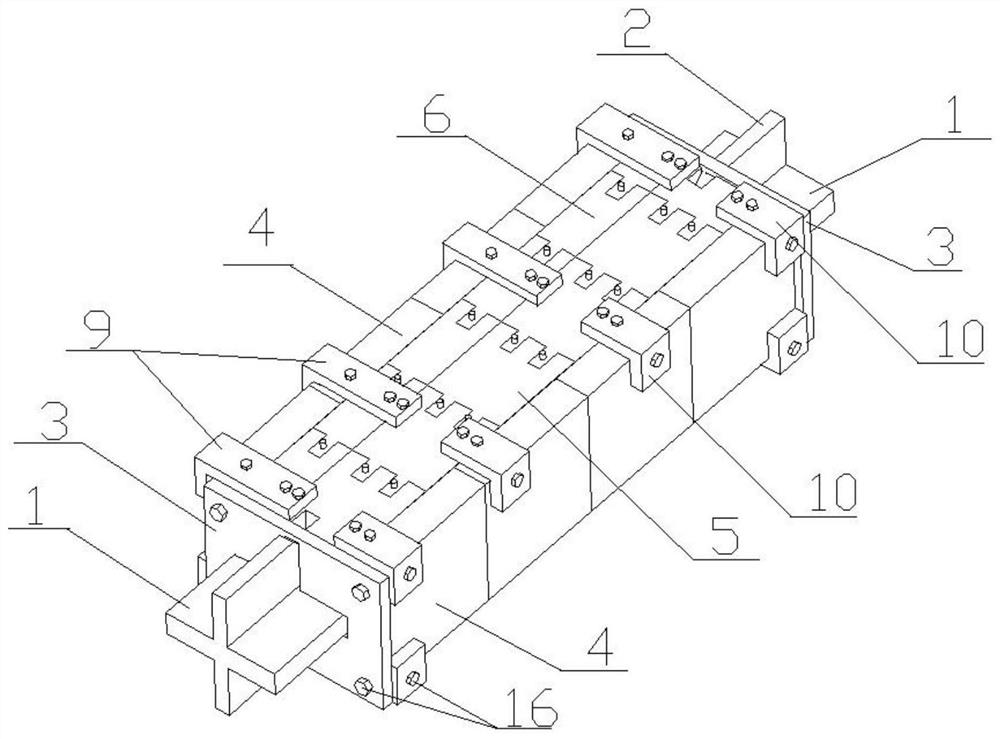

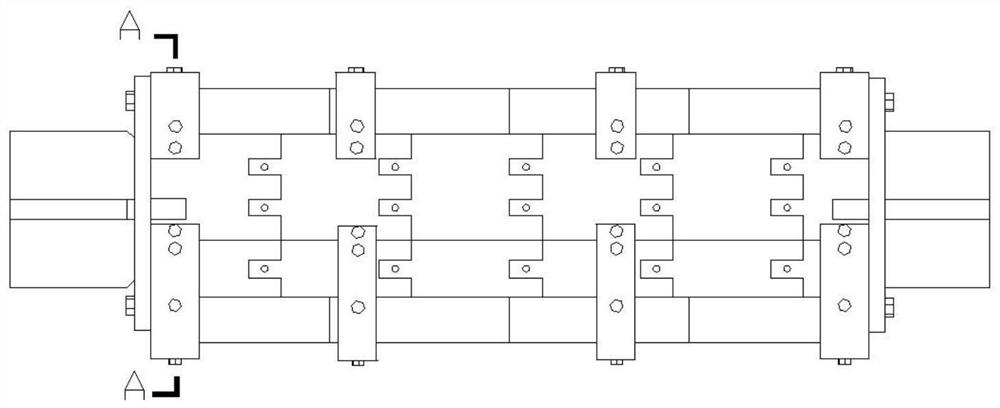

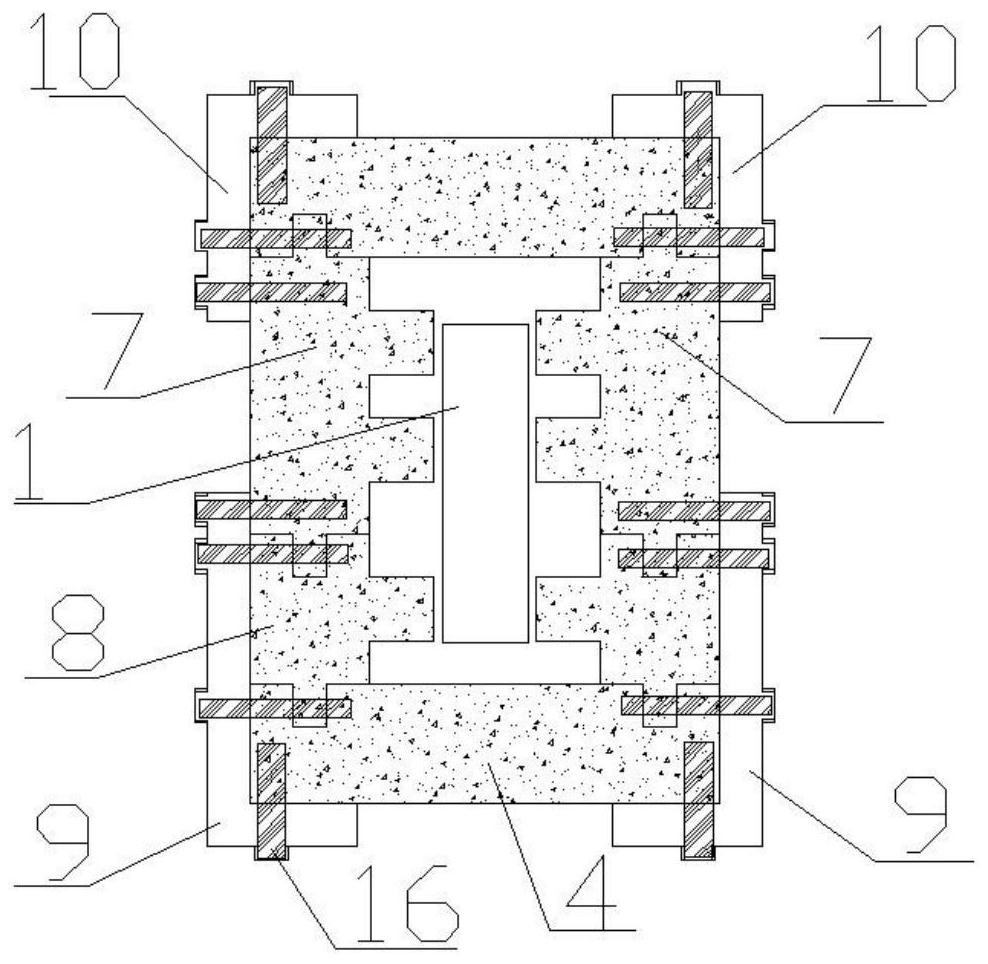

[0037] refer to Figure 1-16 , a self-locking assembled anti-buckling brace for a nuclear island structure, comprising a core plate 1 and a stiffener 2, the core plate 1 is covered with a sleeve, and the sleeve includes: a 4 concrete-filled steel tube block, a 5 concrete-filled steel tube block , CFST block c 6, CFST block d 7, CFST block e 8, CFST block f 17, CFST block g 18;

[0038] Concave-convex blocks that can cooperate with each other are arranged on each steel tube concrete, and the sleeve is assembled by splicing and assembling multiple steel tube concrete, steel tube concrete block b 5, steel tube concrete block c 6, steel tube concrete block d 7, steel tube concrete block e 8 , CFST block f 17 and CFST block g 18 are restrained and fixed by self-locking devices, and CFST block a and other CFST blocks are fixed by long angle steel 9 or short angle steel 10;

[0039] Both ends of the sleeve are fixed with a cover plate 3 by bolts, and the core plate 1 runs through an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com