Capacitor lead wire connecting structure and manufacturing method thereof

A connection structure and manufacturing method technology, which is applied in the field of capacitors, can solve the problems that the copper tube cannot be completely attached to the copper stranded wire, the resistance at the joint is large, and the copper stranded wire is loose, so as to reduce inspection time, reduce heat generation, and secure high performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

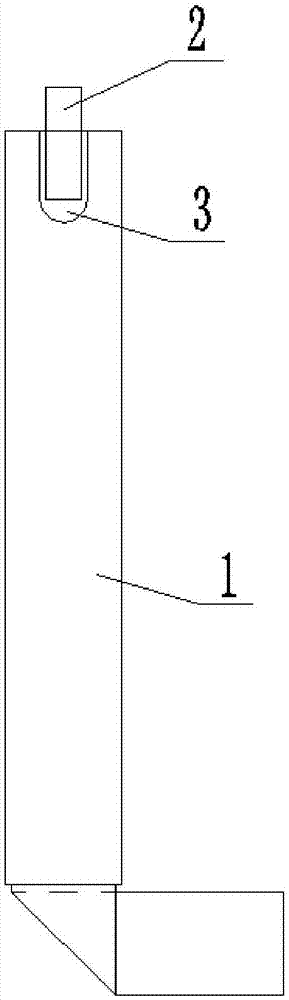

[0029] Such as figure 1 The connection structure of the lead-out wires of capacitors shown includes a core lead-out connecting piece 1 and a copper stranded wire 2, the end face of the core lead-out connecting piece 1 is provided with a fixing groove 3, and the copper stranded wire 2 is arranged in the fixing groove 3 Inside; the depth of the fixing groove 3 is 15-25mm; the aperture of the fixing groove 3 is equal to the diameter of the copper strand 2; the copper strand 2 is set in the fixing groove 3 by welding.

[0030] A method for making a connection structure of capacitor lead wires, comprising the following steps:

[0031] Step 1, using a mold to stamp the fixing groove 3 at one end of the connecting piece 1 leading out of the core;

[0032] The size of the fixing groove 3 is moderate and reasonable, and it needs to be matched with the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com