Tool plate for embedded bolt assembly installation and checking

A technology of component installation and pre-embedded bolts, applied in measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as inability to accurately inspect and inspection of the overall twist of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

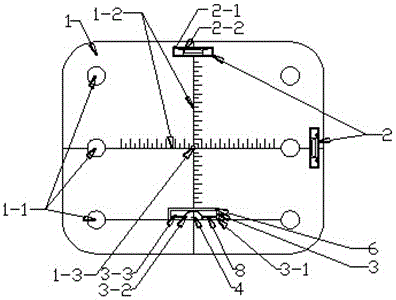

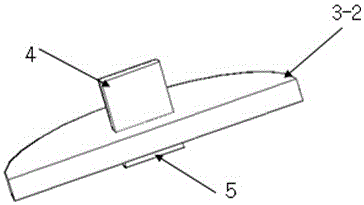

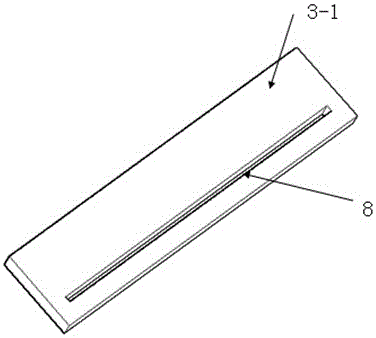

[0020] Embodiments of the present invention: use hard transparent plastic to customize the tool plate body 1 with the same thickness, size and shape as the expected mounting parts in the future; set target bolt holes 1-1 at the corresponding positions of the tool plate body 1; Set the cross scale 1-2 at the vertical and horizontal center of the body 1, and the accuracy is controlled at 1mm; set the centering hole 1-3 at the center of the tool plate body 1, and the hole radius is 5mm; The edge position is centered on one side according to the size of the horizontal tube, and two horizontal tube reserved holes 2-1 are set, and the size of the hole matches the purchased level tube 2-2; a special angle dial is set on one side of the lateral edge of the tool plate body 1 (3-2) The thickness and size match the protractor moving cavity 3-3, such as Figure 4 As shown, a chute 7 is arranged at the bottom of the cavity, and the chute corresponds to the protrusion on the back of the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com