Top-combustion type hot-blast stove refractory material sectioned masonry construction method

A construction method and hot blast stove technology, which is applied in the field of sectioned masonry construction of top-fired hot blast stove refractory materials, can solve the problems of unfavorable saving of construction period, unfavorable construction personnel safety, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by specific examples.

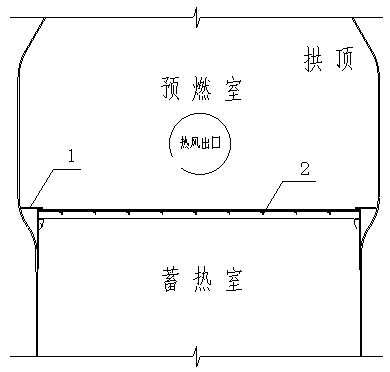

[0028] like figure 1 , shown, a top-combustion hot blast stove refractory segmented masonry construction method, including

[0029] Step 1. Reasonably design and erect platform 2 according to the size of the construction platform required to be erected on the brick pallet 1 and the quality of persons, objects and machinery to ensure that it meets the safety requirements;

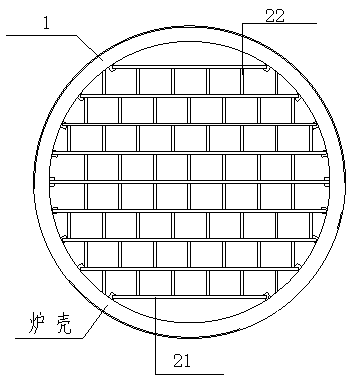

[0030] Step 2, set up the construction platform described in step 1 on the brick pallet; as figure 2 As shown, the construction platform is circular with a diameter of 10m, and is composed of a C25a supporting beam 21 and an L100×8 connecting beam 22 with a 10mm thick flexible rubber pad and a 50mm thick wooden springboard.

[0031] Step 3. Simultaneously build refractory materials in the lower regenerator of the furnace body and the pre-combustion chamber above the construction platform;

[0032] Step 3.1, the masonry proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com