Building and supporting method for semiring brick on hoogoven's warm-air duct inside lining

A technology of hot air pipes and masonry, which is applied in the direction of brick blast furnaces, etc., can solve problems such as easy to use wrongly, the tube shell burns red, and the quality of masonry is difficult to guarantee, so as to ensure the quality of masonry, avoid mixing, and facilitate popularization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

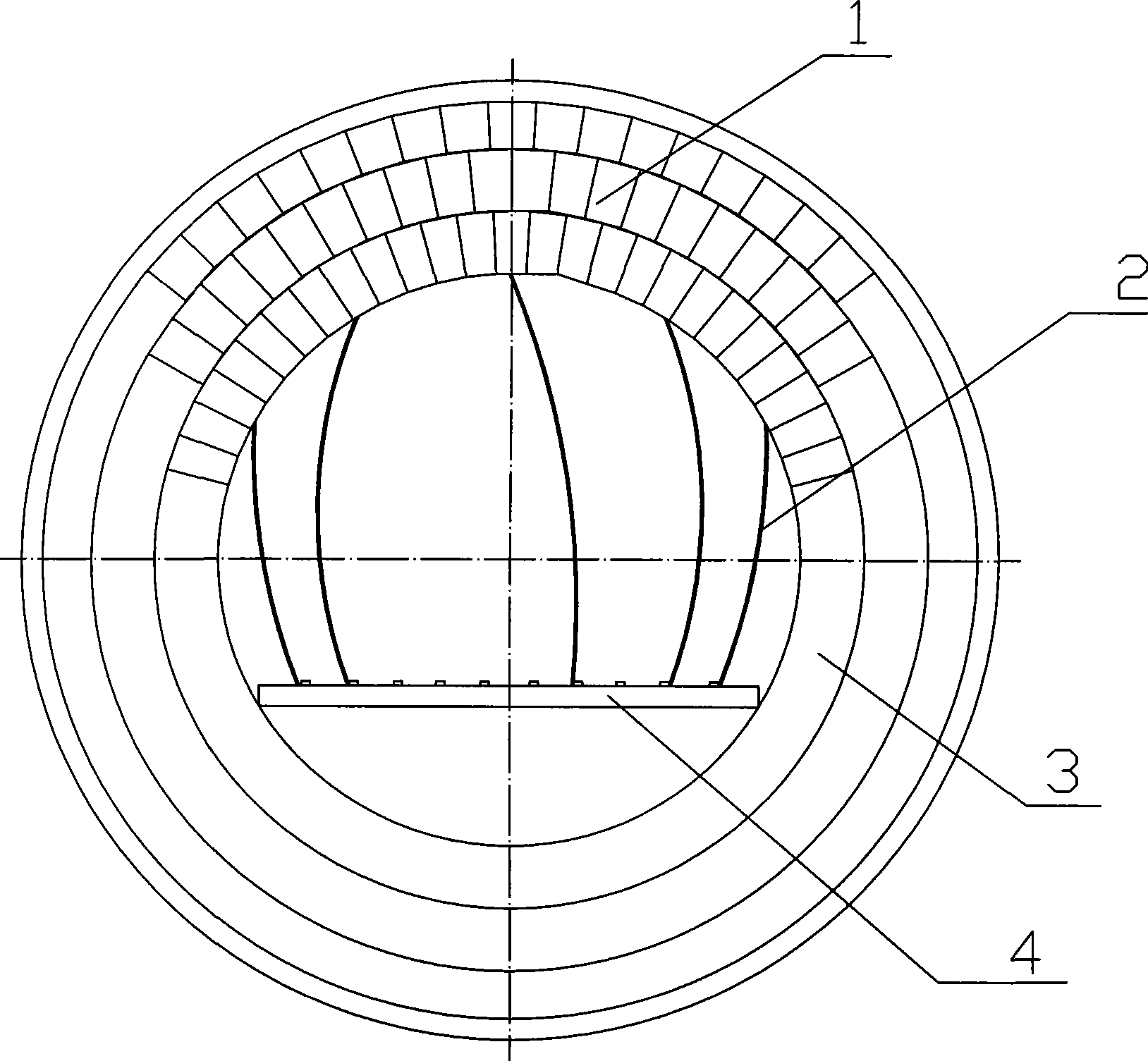

[0016] The Hogovin-type hot air duct lining upper half-ring brick masonry support method provided by the present invention is carried out on the basis of completing the Hogovin-type hot-air duct lining lower half-ring brick. The method is: from the outer ring to the The inner ring is built ring by ring, and the concealed construction is changed into an open construction. In the process of laying light bricks and heavy bricks, strips and matching wooden boards are used as temporary supports. Among them: put the two ends of the wooden boards On the lower half-ring brick of the inner lining of the pipeline, use the upper end of the strip piece to withstand the upper half-ring brick that is being laid. The lower end of the strip piece is placed on the wooden board and the horizontal spacer on the wooden board prevents it from sliding until the mud dries up. Or after closing the door on the upper half ring, take down the strips; after the masonry is completed, remove the strips and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com