Construction method for controlling masonry horizontal mortar joint thickness and vertical masonry mortar joint width

A construction method and technology of mortar joints, applied in the processing of building materials, construction, building construction, etc., can solve the problems of affecting the strength, reducing the appearance, and the difficulty of accurately controlling the thickness of the mortar joints, so as to avoid material waste and ensure masonry Quality, the effect of improving the perceived quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

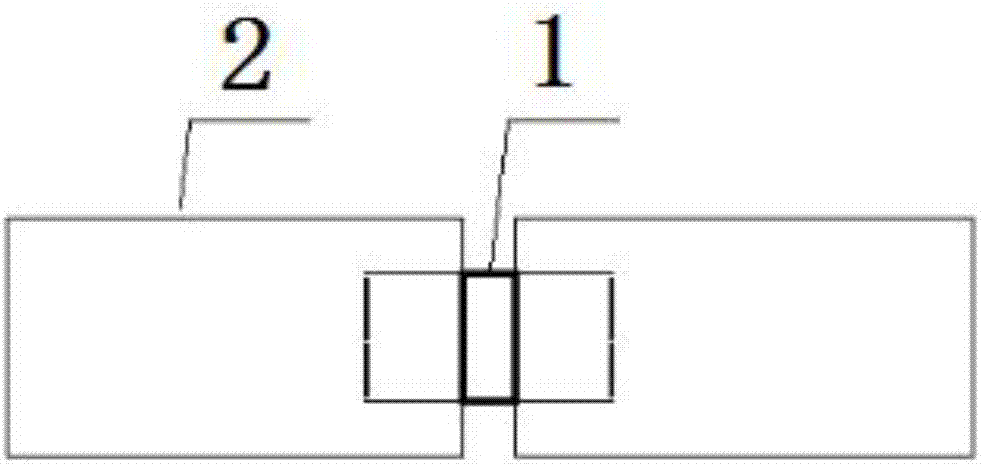

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention controls the thickness of masonry horizontal mortar joint and the construction method of vertical mortar joint width and comprises the following steps:

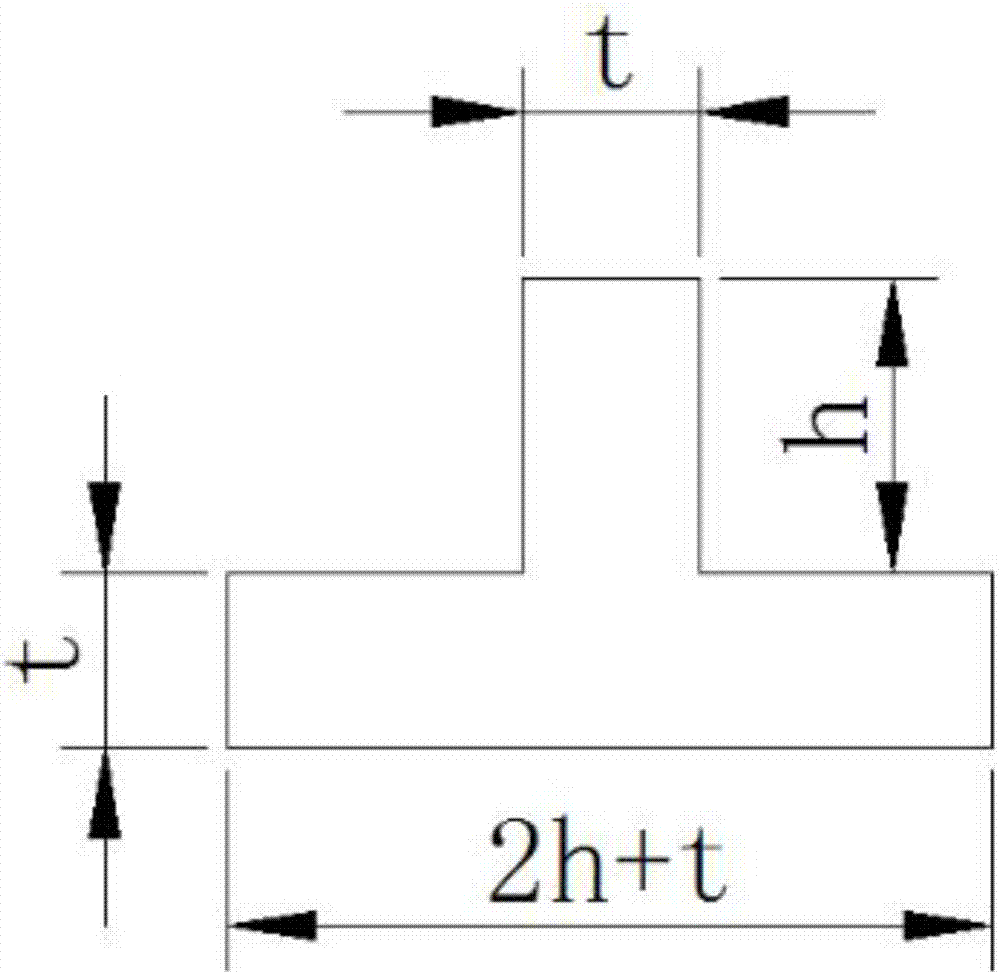

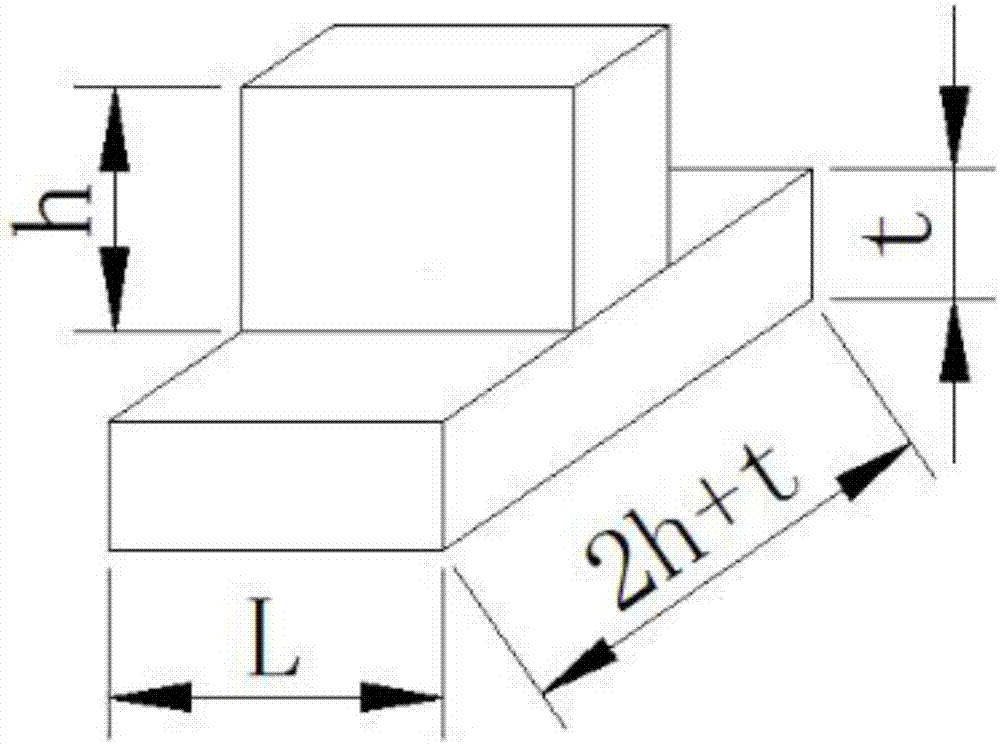

[0027] (1) production figure 1 , figure 2 As shown in the inverted T-shaped mortar joint control member 1, if the width of the bottom is L, the length of the bottom is K, the thickness of the bottom is t, the height of the upper protrusion is h, and the width of the upper protrusion is t, then: L should be 2-3cm, preferably no more than 1 / 3 of the width of the block 2; t is a uniform value between 8-12mm, depending on the thickness of the horizontal mortar joint and the width of the vertical mortar joint required by the mason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com