Construction method for planting wall lacing bars after pre-burying of sleeve assemblies

A technology of pre-embedded sleeves and construction methods, which is applied in the direction of construction, building structure, and building materials processing, etc., can solve the problems of poor gripping force and easy damage to structural steel bars, etc., and achieve convenient construction, reliable installation quality, and mechanical reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

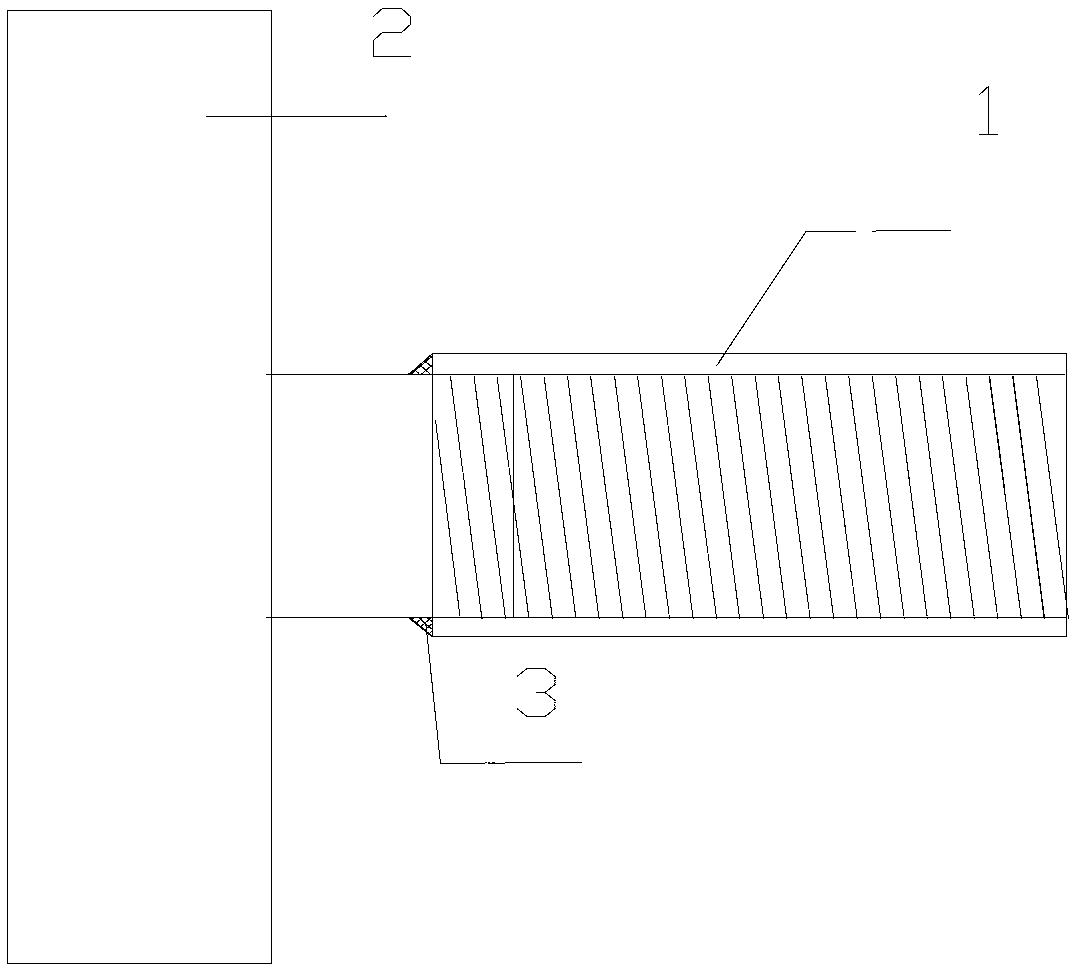

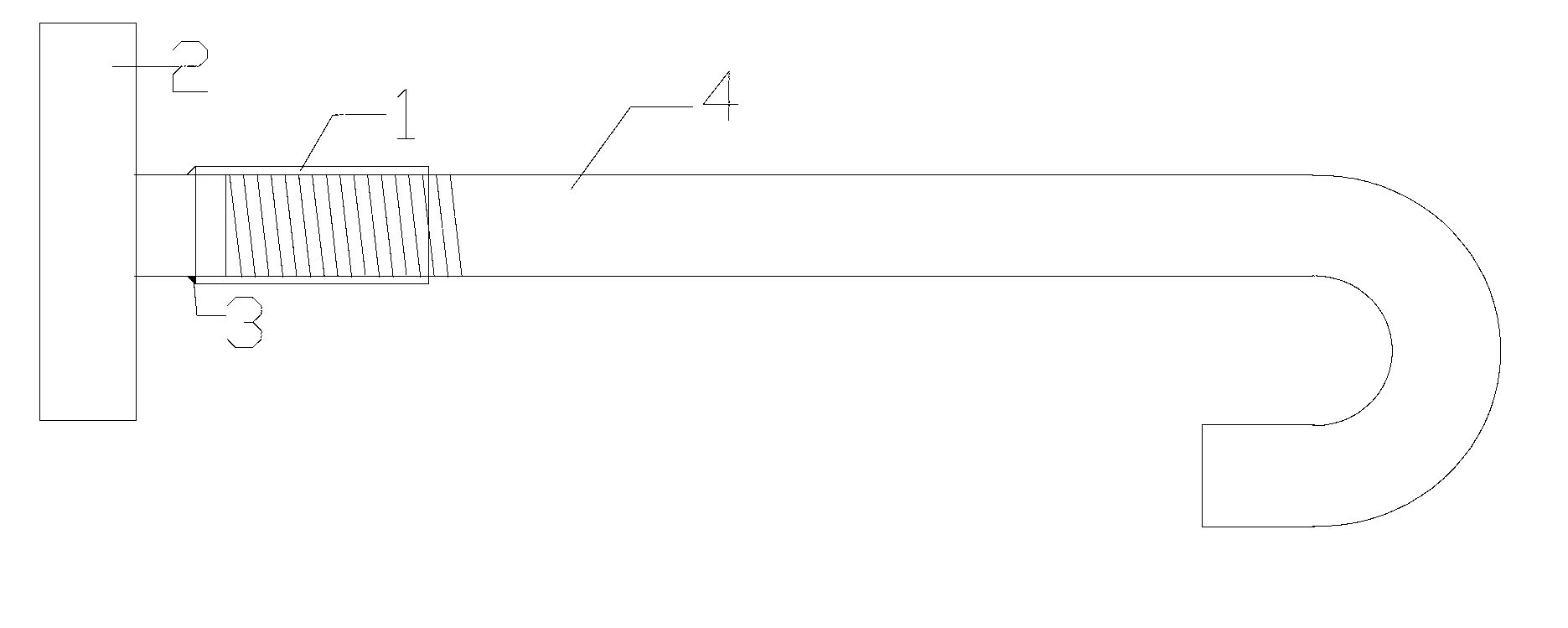

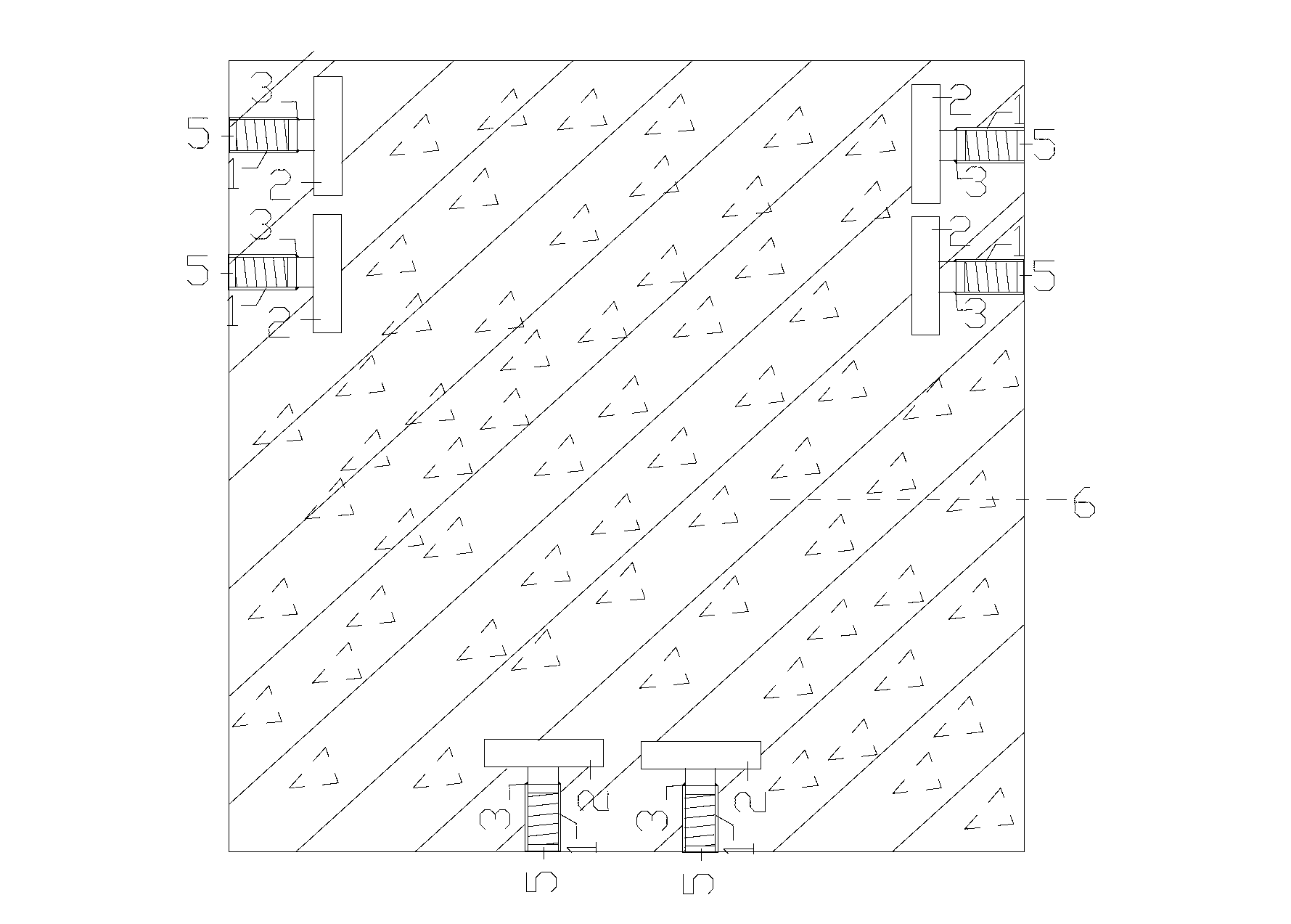

[0034] Adopt an electric welding machine to weld the Φ6 sleeve 1 on the straight rod of the T-shaped mechanical anchoring tendon 2 to form a sleeve assembly, and the sleeve 1 is provided with threads; (2) before the concrete structure pours the concrete, the sleeve assembly According to the design requirements, it is pre-buried at the wall tie bar position of the concrete structure, and the plugging plastic bolt 5 is screwed on the end of each sleeve; (3) after the concrete pouring of the concrete structure 6 is completed, use a screwdriver to screw the end of the sleeve 1 Unscrew the blocking plastic bolt 5 at the top, then screw the wall tie 4 into the sleeve 1, then tighten the wall tie 4 and the sleeve 1 with a wrench, and finally use a torque wrench to check that the wall tie 4 and the sleeve 1 are qualified. The sleeve 1 is connected into one body through a screw; (4) When the rear wall 7 is built, the wall tie bars 4 are placed in the mortar joints of the rear wall 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com