Prefabricated assembling joint

A prefabricated assembly and node technology, which is applied in the direction of architecture and building construction, can solve problems such as difficult drilling, construction difficulty, and connection difficulty, and achieve the effects of saving resources and energy, reliable mechanical properties, and outstanding fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

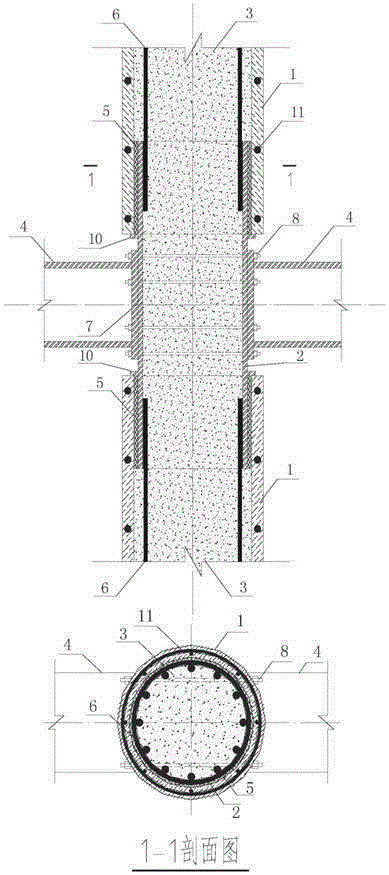

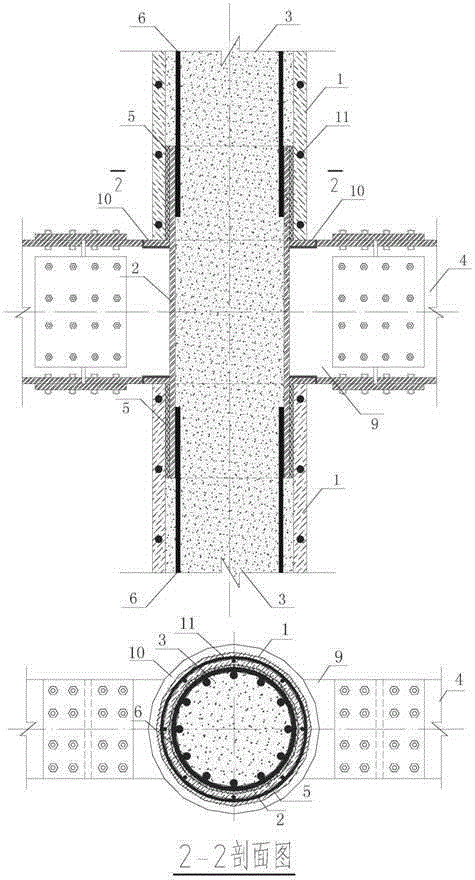

specific Embodiment approach 2

[0050] The invention is attached figure 2 As shown, it is characterized in that the prefabricated active powder concrete pipe (1) is combined with the steel beam (4) through the connecting steel pipe (2); the prefabricated active powder concrete pipe (1) of the upper and lower layers adopts the adhesive (5) through the connecting steel pipe ( 2) to realize the upper and lower connection, the longitudinal reinforcement (6) of the internal concrete column (3) is welded on the inner wall of the connecting steel pipe (1); the steel beam (4) is connected by the short leg beam (9) welded on the side of the connecting steel pipe (2) On the node; after the assembly is completed, the internal concrete column (3) is poured in the prefabricated active powder concrete pipe (1) and the connecting steel pipe (2), such as figure 2 shown. It is characterized in that the connecting steel pipe (2) is welded with two reinforcing rings (10), and the assembly of the prefabricated active powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com