Gypsum block-based assembled wall building method and gypsum block

A gypsum block and prefabricated technology, used in walls, buildings, building components, etc., can solve the problems of complicated wall masonry, difficult to achieve uniform thickness, and easy spillage of glue Masonry quality and wall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

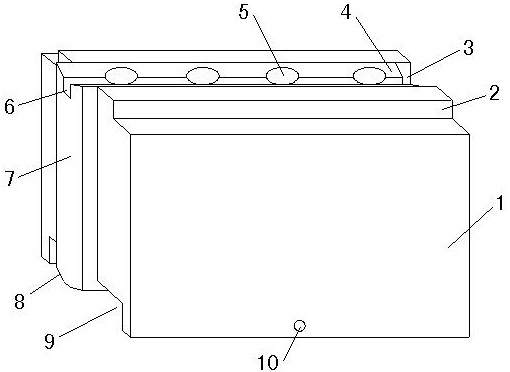

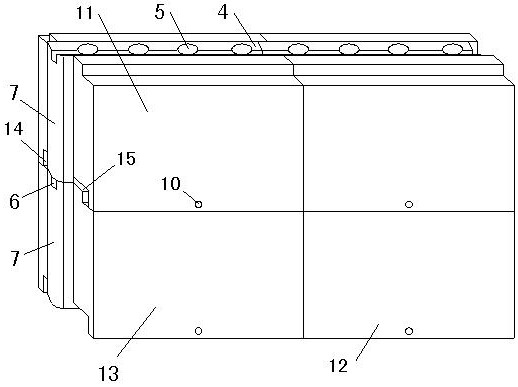

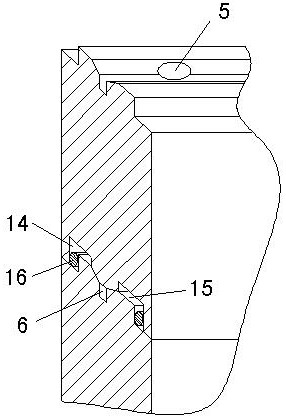

[0027] Gypsum blocks used in the present invention, such as figure 1 As shown, including a gypsum block 1, the bottom surface of the gypsum block 1 is provided with a bottom groove 9 along the length direction, the top surface of the gypsum block 1 is provided with a top platform 2, the width of the bottom groove 9 is greater than the width of the top platform 2, and the bottom groove 9 The depth is greater than the height of the top platform 2. The bottom groove 9 is provided with a vertical positioning boss 8, and the top platform 2 is provided with a vertical positioning groove 4 corresponding to the vertical positioning boss 8, so as to realize the vertical positioning of the upper and lower gypsum blocks. The top platform 2 is provided with a vertical threading hole 5 penetrating through the top surface and the bottom surface of the gypsum block 1 . The two sides of the gypsum block 1 along the length direction are respectively provided with a lateral positioning boss 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com