Electric control cabinet and assembly method thereof

A technology for electric control cabinets and cabinets, applied in the field of electric control cabinets, can solve the problems of inconvenient assembly mode, large volume of electric control cabinets, poor anti-corrosion effect, etc., and achieve the effects of efficient heat dissipation, firm installation, and efficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

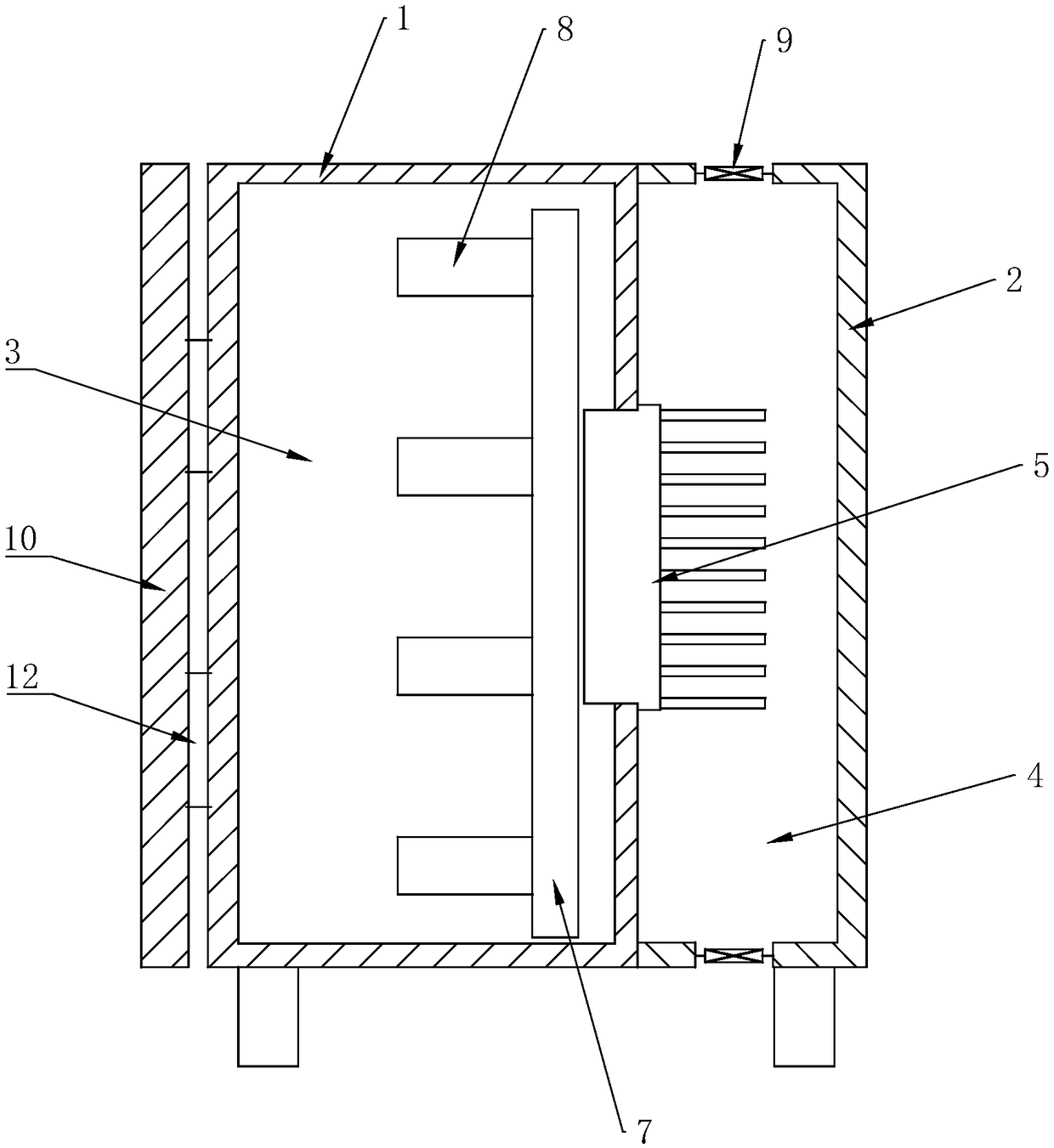

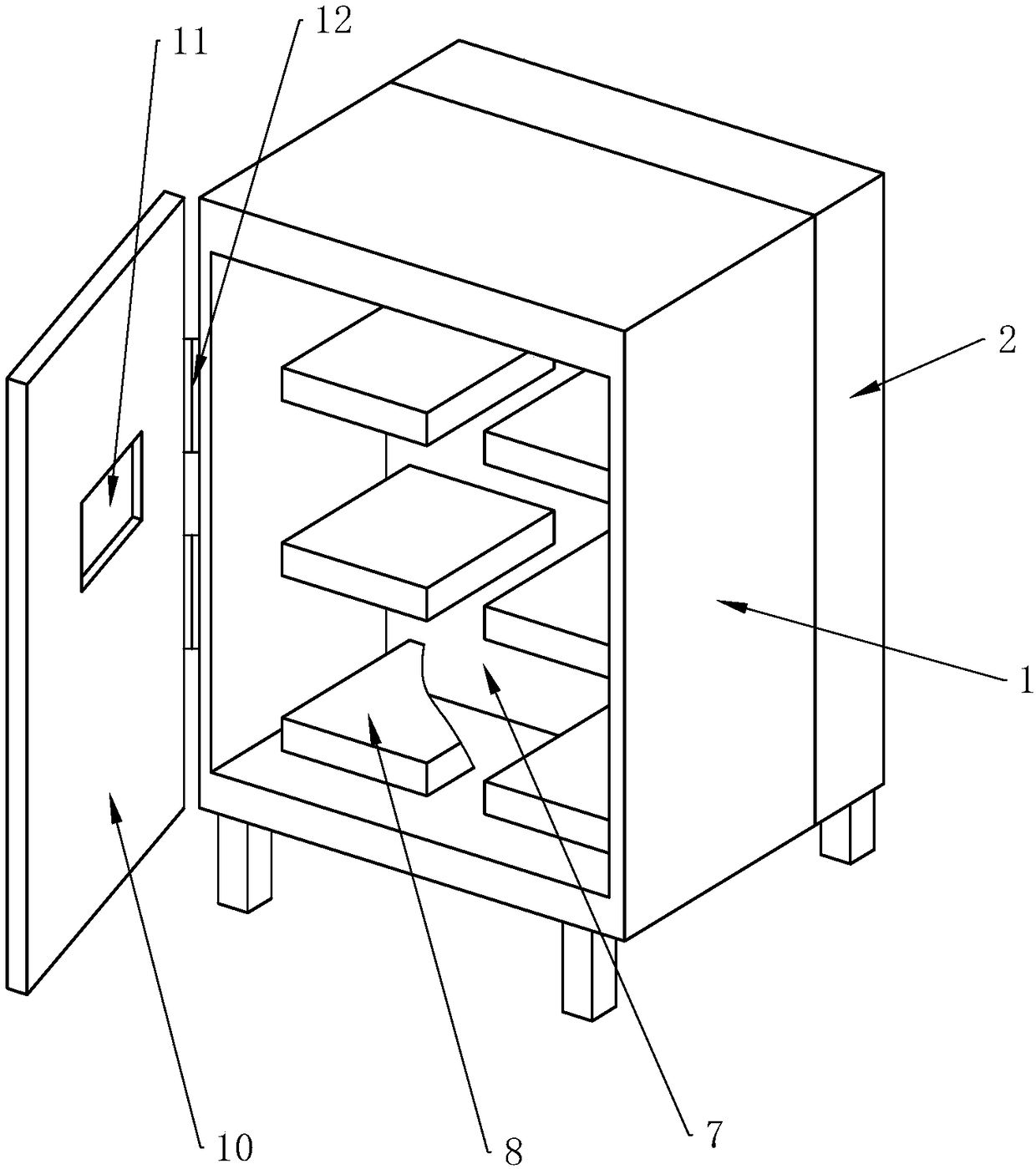

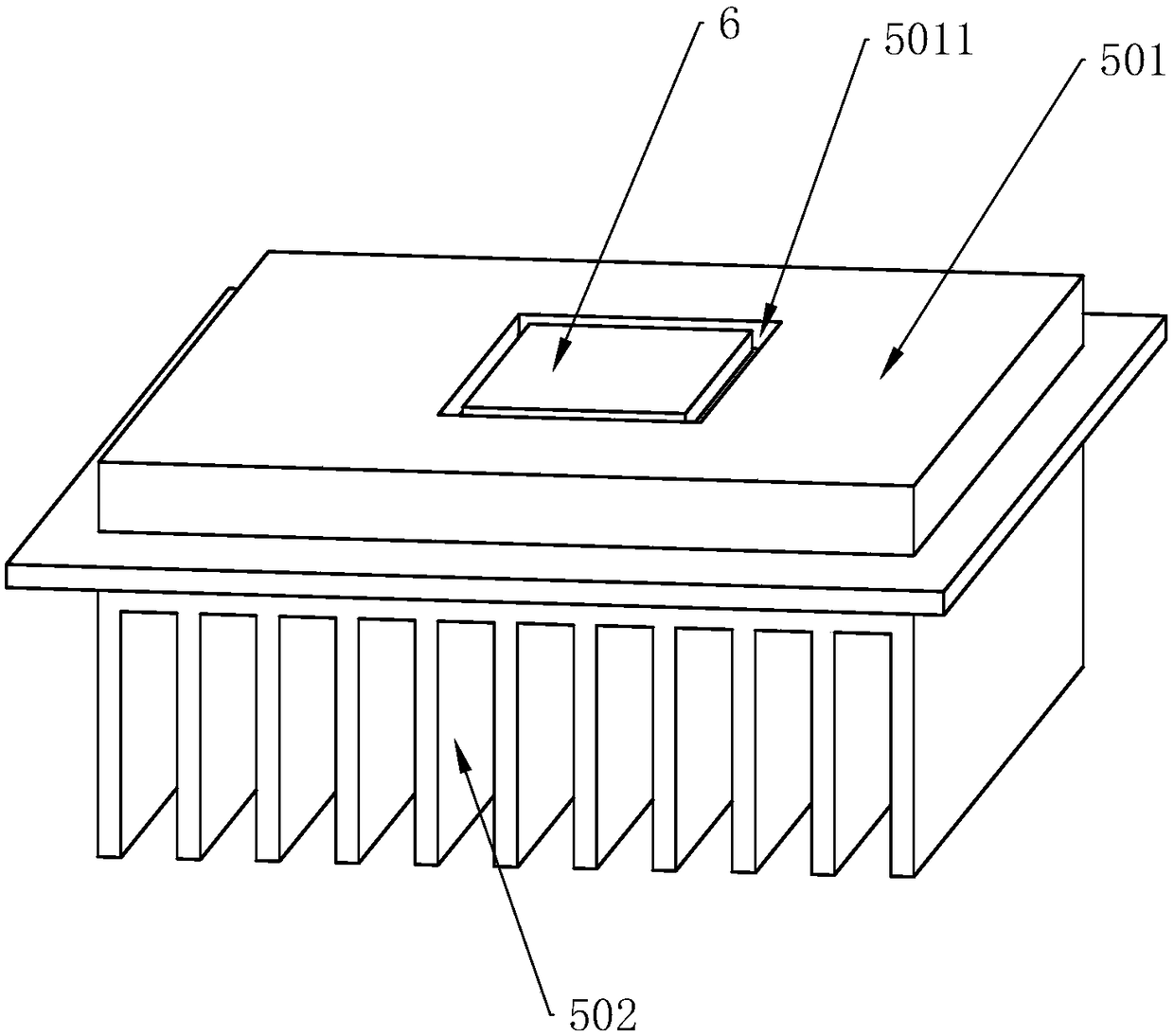

[0045] An electric control cabinet, the cabinet body includes an explosion-proof casing 1 and a ventilation casing 2, the explosion-proof casing 1 is surrounded by an explosion-proof cavity 3, the ventilation casing 2 is located on one side of the explosion-proof casing 1, and is connected with the explosion-proof casing The body 1 forms a ventilation cavity 4; the side of the explosion-proof casing 1 close to the ventilation casing 2 is provided with a mounting hole, and the explosion-proof cavity 3 is connected to the ventilation cavity 4 by using the mounting hole, and a heat dissipation device is installed on the mounting hole; The explosion-proof cavity 3 formed by the explosion-proof casing 1 and the heat dissipation device sealed with the explosion-proof casing 1 realize the sealed protection of the equipment and circuits in the power distribution cabinet, and the explosion-proof cavity 3 and the ventilation cavity are realized by using the heat dissipation device. 4. Th...

Embodiment 2

[0055] This example has the same structure as Example 1, the difference is that the anti-corrosion material used in this example is prepared from the following components: 30-50 silicone modified acrylic resin, 20 zinc tripolyphosphate, 10 toluenesulfonic acid , hydroxyethylidene diphosphonic acid 9, 1389MS auxiliary agent (King Industries, Inc. company provides) 10, fumaric acid 5, dimethyl sulfoxide 3, deionized water 25, the preparation method of described anticorrosion material, comprises as follows Step: S1. After preparing the materials, add deionized water, zinc tripolyphosphate, toluenesulfonic acid, hydroxyethylidene diphosphonic acid, and 1389MS additives to the reactor in sequence, and stir at a medium speed of 110 rpm until uniform; S2. Put the stirred slurry into a sand mill and grind it to a qualified fineness≦40μm; S3. Add fumaric acid, dimethyl sulfoxide, and silicone-modified acrylic resin to the ground slurry in sequence, and adjust The viscosity of the produ...

Embodiment 3

[0057] This example has the same structure as Example 1, the difference is that the anti-corrosion material used in this example is prepared from the following components: silicone modified acrylic resin 40, zinc tripolyphosphate 15, toluenesulfonic acid 8, hydroxyl Ethylidene diphosphonic acid 7, 1389MS auxiliary agent (King Industries, Inc. company provides) 8, fumaric acid 4, dimethyl sulfoxide 2, deionized water 20, the preparation method of described anticorrosion material, comprises the steps: S1. After preparing the materials, add deionized water, zinc tripolyphosphate, toluenesulfonic acid, hydroxyethylidene diphosphonic acid, and 1389MS additives to the reactor in sequence, and stir at a medium speed of 100 rpm until uniform; S2. Put the stirred slurry into a sand mill and grind it to a qualified fineness≦40μm; S3, add fumaric acid, dimethyl sulfoxide, and silicone-modified acrylic resin to the ground slurry in sequence to adjust the fineness of the product. Viscosity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com