Water-based high-temperature-resistant anti-rust multifunctional coating and preparation method thereof

A rust-resistant, high-temperature-resistant pigment technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problem that the comprehensive performance is difficult to meet customer requirements, and achieve simple and convenient construction performance, good stability, and good attachment. Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

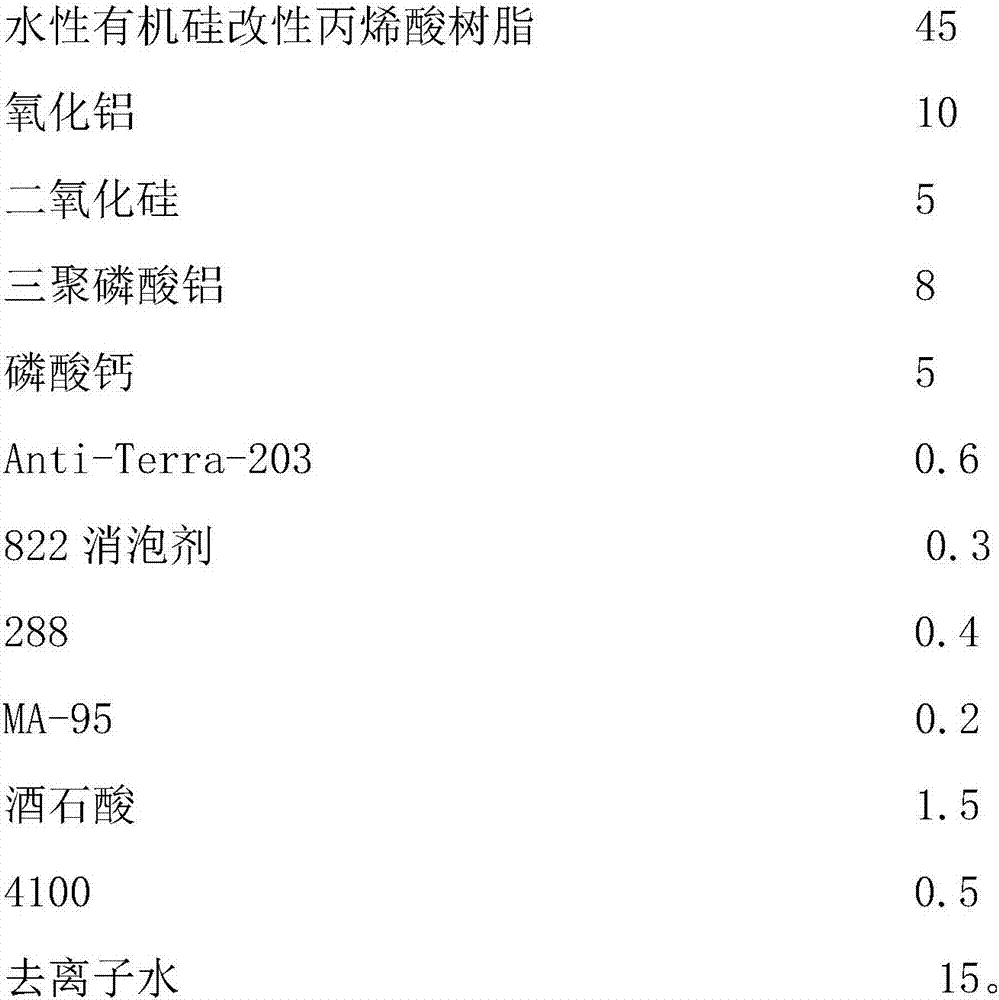

[0031] A water-based high-temperature-resistant rust-resistant multifunctional coating is prepared from the following raw materials in parts by weight:

[0032]

[0033] The water-based high-temperature-resistant rust-proof multifunctional coating with rust of the present embodiment, its preparation steps are:

[0034] S1. After preparing the materials, add deionized water, alumina, silicon dioxide, aluminum tripolyphosphate, calcium phosphate, Ante-Terra-203, 822 to the reaction kettle in sequence, and stir evenly;

[0035] S2. Put the uniformly stirred slurry into a sand mill and grind it to a qualified fineness;

[0036] S3. Add MA-95, tartaric acid, water-based silicone modified acrylic resin, and 4100 to the ground slurry in sequence. After stirring at a medium speed, add 288 while stirring, and adjust the product viscosity to the required range to obtain finished product.

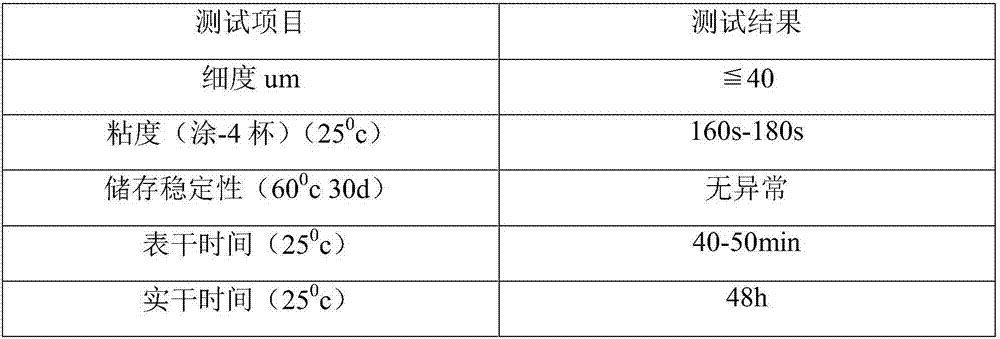

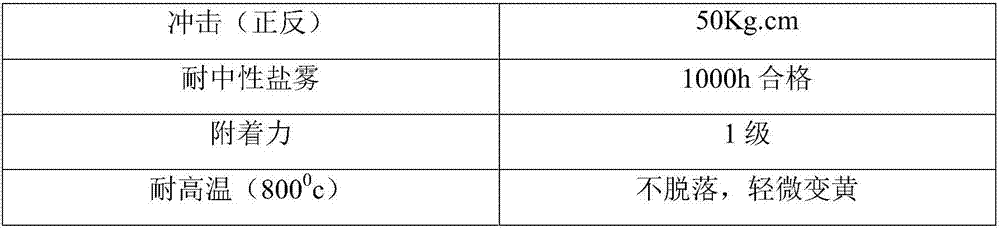

[0037] According to relevant national standards, the basic performance of this embodiment is ...

Embodiment 2

[0041] A water-based high-temperature-resistant rust-resistant multifunctional coating is prepared from the following raw materials in parts by weight:

[0042]

[0043] The water-based high-temperature-resistant rust-proof multifunctional coating with rust of the present embodiment, its preparation steps are:

[0044] S1. After preparing the materials, add deionized water, aluminum oxide, titanium oxide, aluminum tripolyphosphate, zinc phosphate, 757W, 822 in sequence to the reactor, and stir evenly;

[0045] S2. Put the uniformly stirred slurry into a sand mill and grind it to a qualified fineness;

[0046] S3. Add MA-95, toluenesulfonic acid, silicone-modified acrylic resin, 4100, 500 to the ground slurry in turn, and stir evenly at a medium speed, then add 299 under stirring to adjust the product viscosity to the requirement range, the finished product can be obtained.

[0047] According to relevant national standards, the basic performance of this embodiment is teste...

Embodiment 3

[0050] A water-based high-temperature-resistant rust-resistant multifunctional coating is prepared from the following raw materials in parts by weight:

[0051]

[0052]

[0053] The water-based high-temperature-resistant rust-proof multifunctional coating with rust of the present embodiment, its preparation steps are:

[0054] S1. After preparing materials, add deionized water, aluminum oxide, titanium oxide, silicon dioxide, aluminum tripolyphosphate, zinc phosphate, 757W, Anti-Terra-203, 822 defoamer to the reactor in sequence, and stir evenly;

[0055] S2. Put the uniformly stirred slurry into a sand mill and grind it to a qualified fineness;

[0056] S3. Add MA-95, toluenesulfonic acid, silicone-modified acrylic resin, 4100, 500 to the ground slurry in turn, and stir at a medium speed, then add 53L and 830W under stirring to adjust the product viscosity To the required range, the finished product can be obtained.

[0057] According to relevant national standards, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com