Integral ultra-high strength concrete-micro-porous ceramic composite sound barrier of high-speed railway box beam

A technology of ultra-high-strength concrete and high-speed railways. It is applied in noise absorption devices and buildings. It can solve the problems of high weather resistance and easy weathering and falling off, and achieve good sound absorption performance, good durability, and high strength and rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential claims made by those skilled in the art based on the above-mentioned content of the present invention Improvements and adjustments also belong to the protection scope of the present invention.

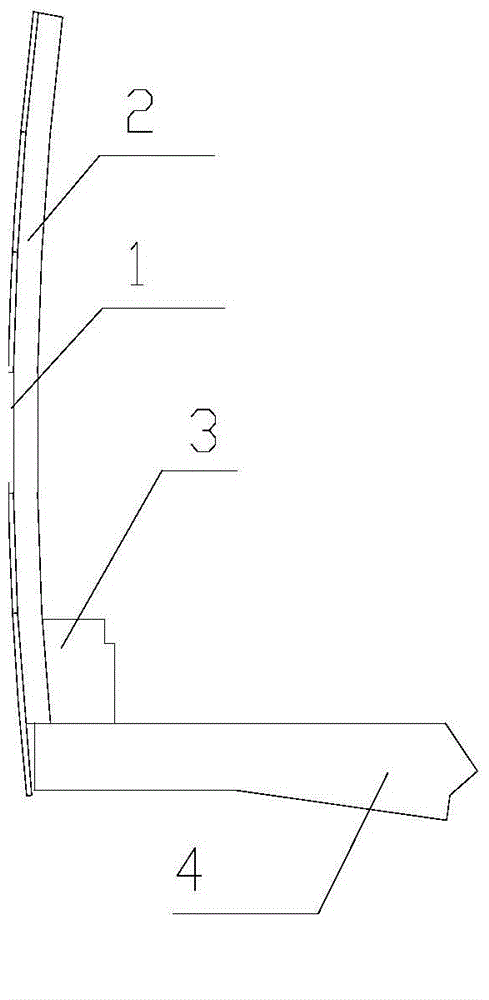

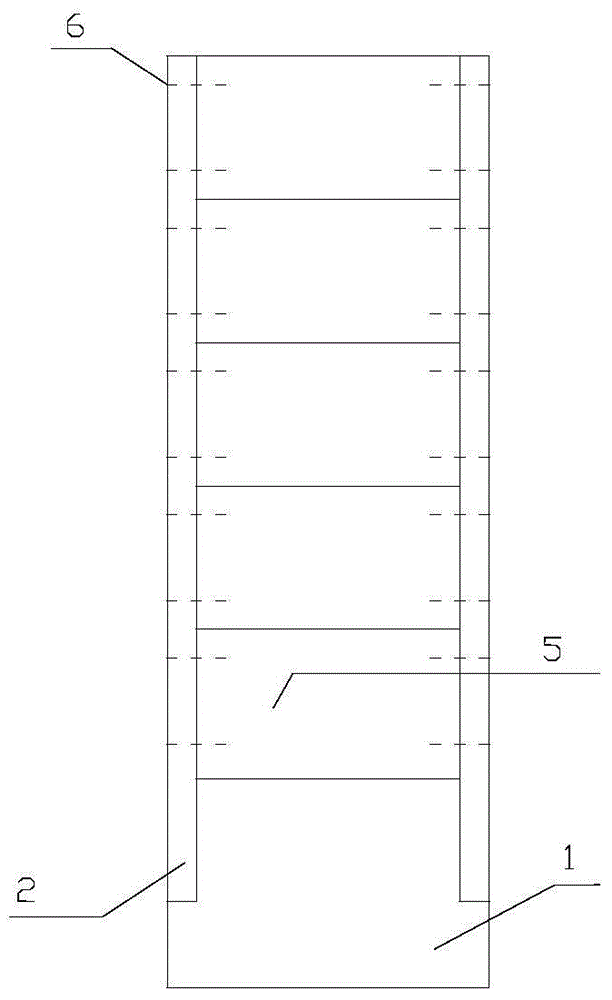

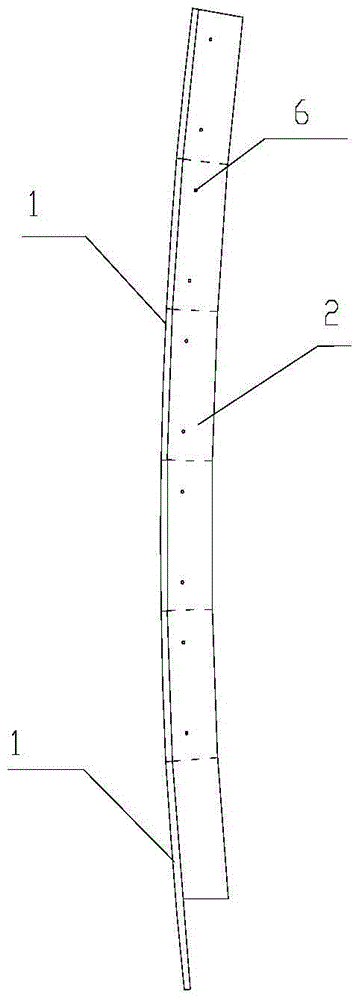

[0044] combine Figure 1 to Figure 15 .

[0045] An ultra-high-strength concrete-microporous ceramic composite sound barrier integrated with high-speed railway box girders, including support rib columns 2 arranged at intervals along the railway line, and a sound-absorbing panel 5 on the side of the railway traffic surface between each two support rib columns 2 1. The back side is the back plate 1, and the lower end of the supporting rib column 2 has a rib column embedded part 21 connected with the railway bridge embedded part 41, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com