Method for controlling building quality of concrete frame structure walls

A frame structure and control method technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of poor quality control effect and weak system, and achieve masonry quality assurance and strong operability , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

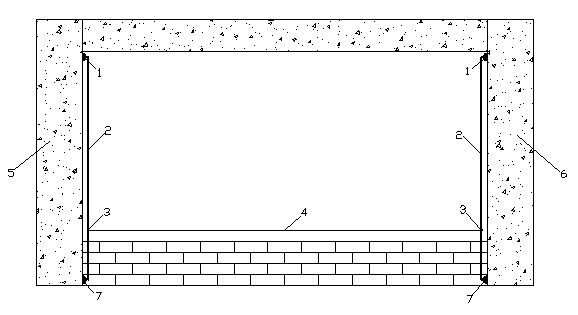

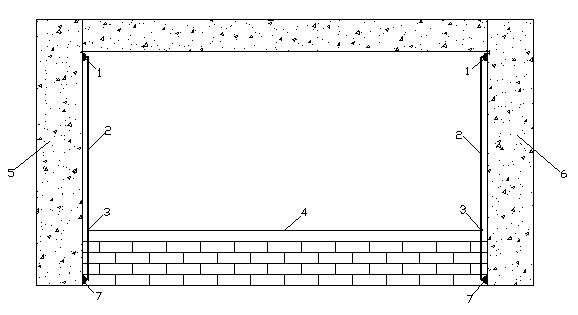

[0017] A method for controlling the masonry quality of a concrete frame structure wall proposed by the present invention has been successfully applied in the new outpatient building project of Ma'anshan People's Hospital. This project is a reinforced concrete frame structure, and the filling wall is made of light masonry When building a wall, first, make a long ruler according to the height of the wall to be built, the thickness of each skin brick (that is, the thickness of each layer of bricks) and the thickness of the mortar joint. Composed of ruler card 3, the height of the vertical ruler 2 is consistent with the height of the masonry wall, and the cross section of the vertical ruler 2 is a flat rectangle, and horizontal scale lines are engraved on the vertical ruler 2 from bottom to top, The position of each horizontal scale mark is corresponding to the horizontal position of the mortar joint between each adjacent leather bricks. On this vertical ruler 2, a rectangular rule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com