Coke oven chute cleaning technology

A chute, coke oven technology, used in coke ovens, petroleum industry, etc., can solve the problems of labor and time-consuming, difficult to clean up thoroughly, unable to directly see the mud and debris, etc., to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

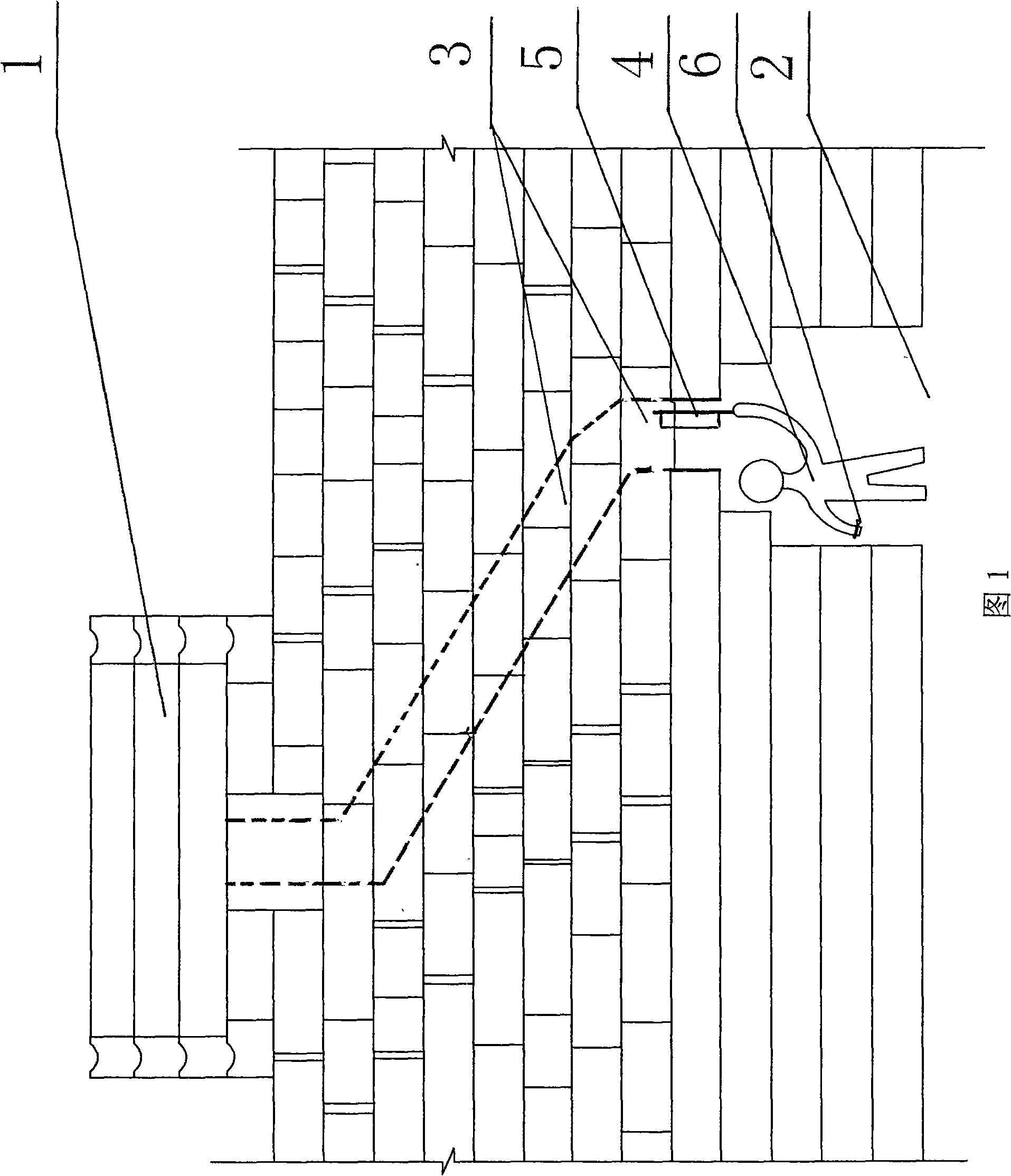

[0009] It can be seen from Figure 1 that a coke oven chute cleaning technology is characterized in that an adjustable mirror angle with a bracket is vertically arranged at the entrance of the chute 3 between the coke oven regenerator 2 and the combustion chamber 1 Glass mirror 5, this glass mirror 5 is preferably with rectangle, and the mirror surface of glass mirror 5 is toward the inside of ramp 3, and when furnace builder 4 enters coke oven ramp 3 to clean, furnace builder 4 irradiates glass mirror with cold light source 6 5 front, the cold light source 6 can be a flashlight or an emergency light or a battery light, and at the same time constantly adjust the angle of the mirror surface of the glass mirror 5 until the reflected light from the mirror surface of the glass mirror 5 clears the inner wall of the ramp 3, especially the corner of the ramp 3 until the glass mirror 5 is fixed, and then, the furnace builder 4 or the cleaning personnel hold tools to completely scrape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com