Mortar joint lining mould for aerated concrete block wall

A technology of aerated concrete and block, which is applied in the processing of building materials, construction, building structure, etc. To avoid the waste of mortar materials, ensure the quality of masonry, and reduce the proficiency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

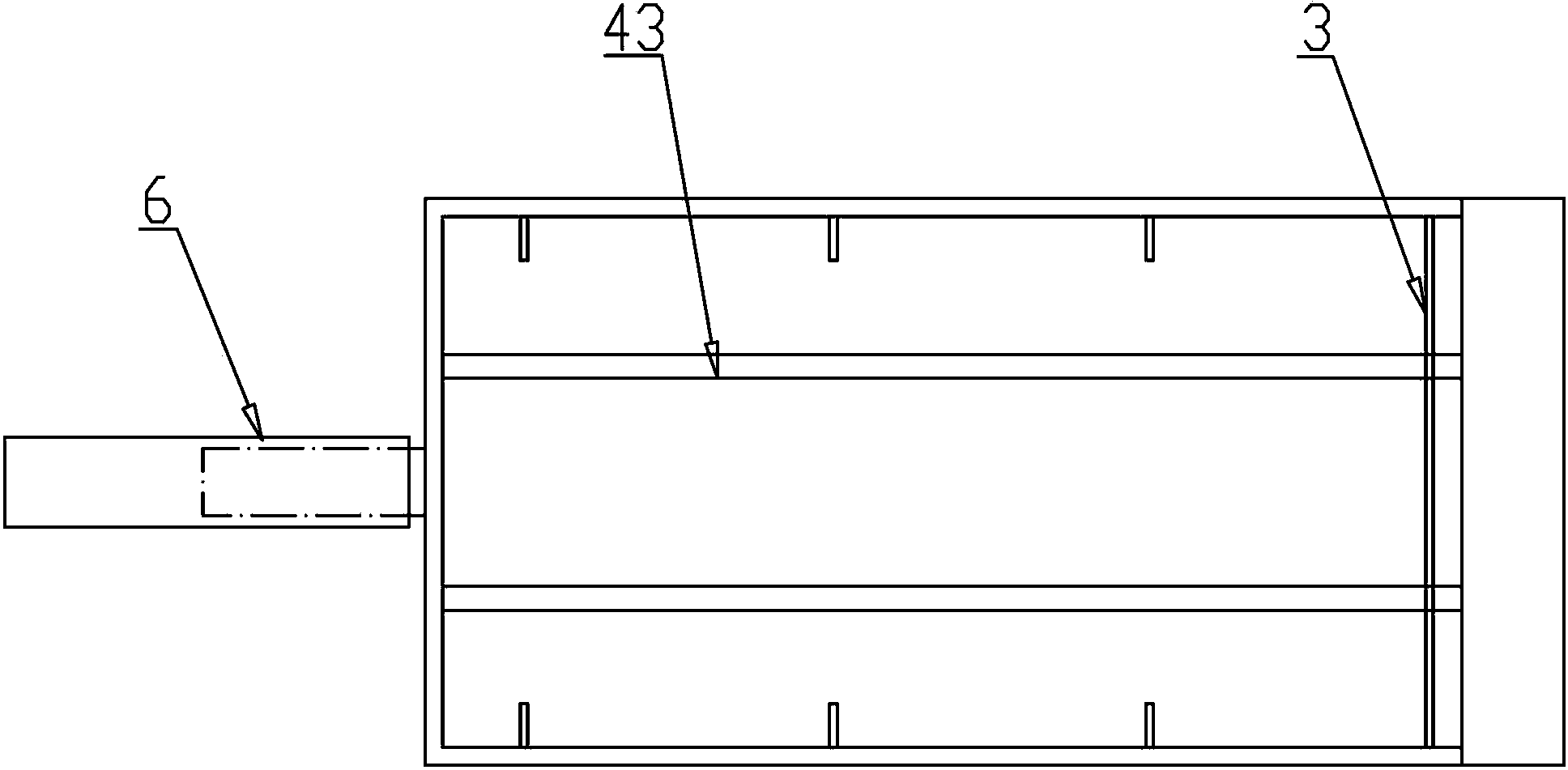

[0031] Such as Figure 5 , 6 Among them, a mortar joint lining mold for aerated concrete block walls, including a bottom frame 4, the bottom frame 4 is a frame composed of oppositely arranged end plates 41 and side plates 42, the end plate 41 and the side plate 42 The upper end face is flush, the length of the end plate 41 is greater than or equal to the width of the upper end face of the brick 7, and the height of the side plate 42 is greater than the height of the end plate 41, so that the lower end inner wall of the side plate 42 is stuck on the side wall of the brick 7.

[0032] With this structure, the end plate 41 is rested on the upper end surface of the brick 7, and the inner wall of the lower end of the side plate 42 is stuck on the side wall of the brick 7, thereby defining the position of the bottom frame 4. After the construction personnel lay the mortar, they only need to Smooth the mortar with a tool, and then demold to control the uniformity, flatness and heigh...

Embodiment 2

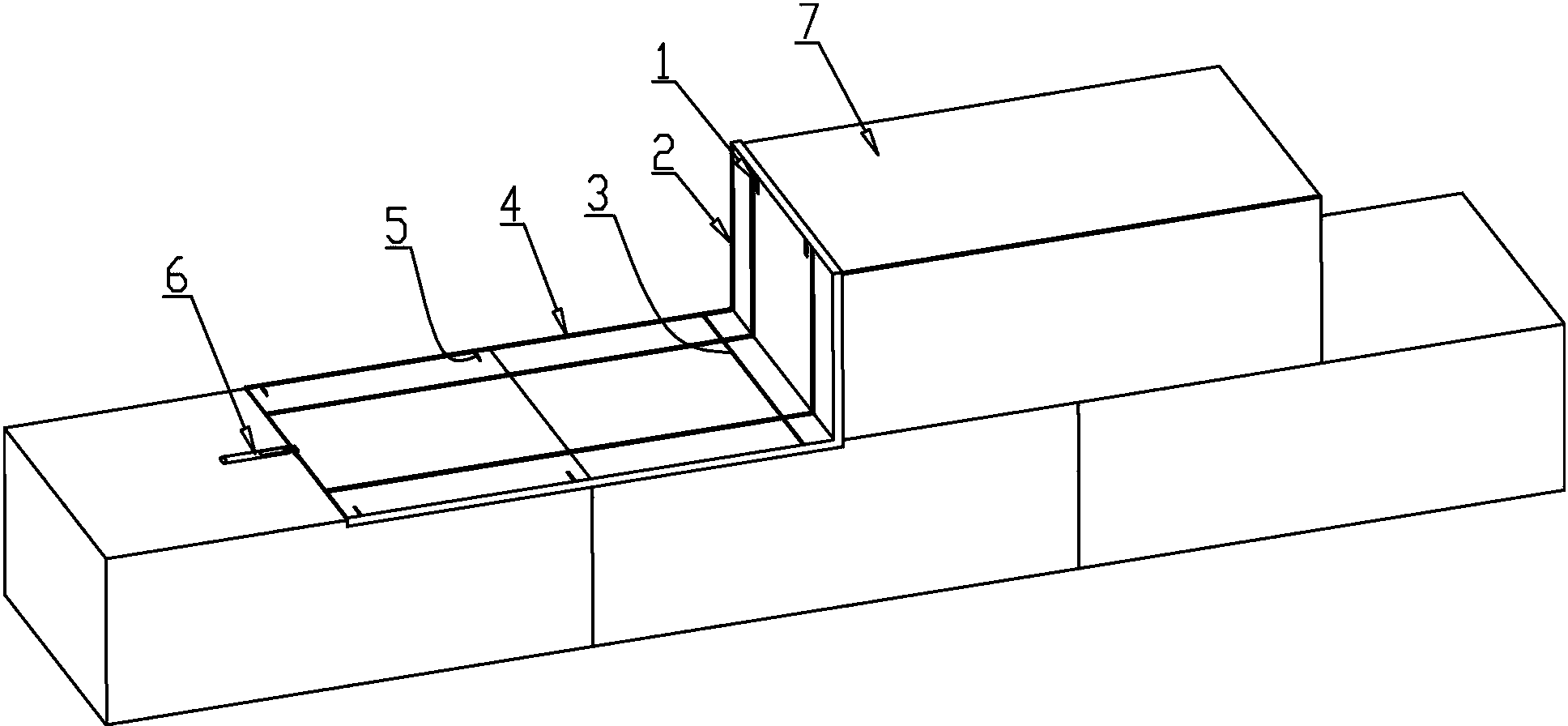

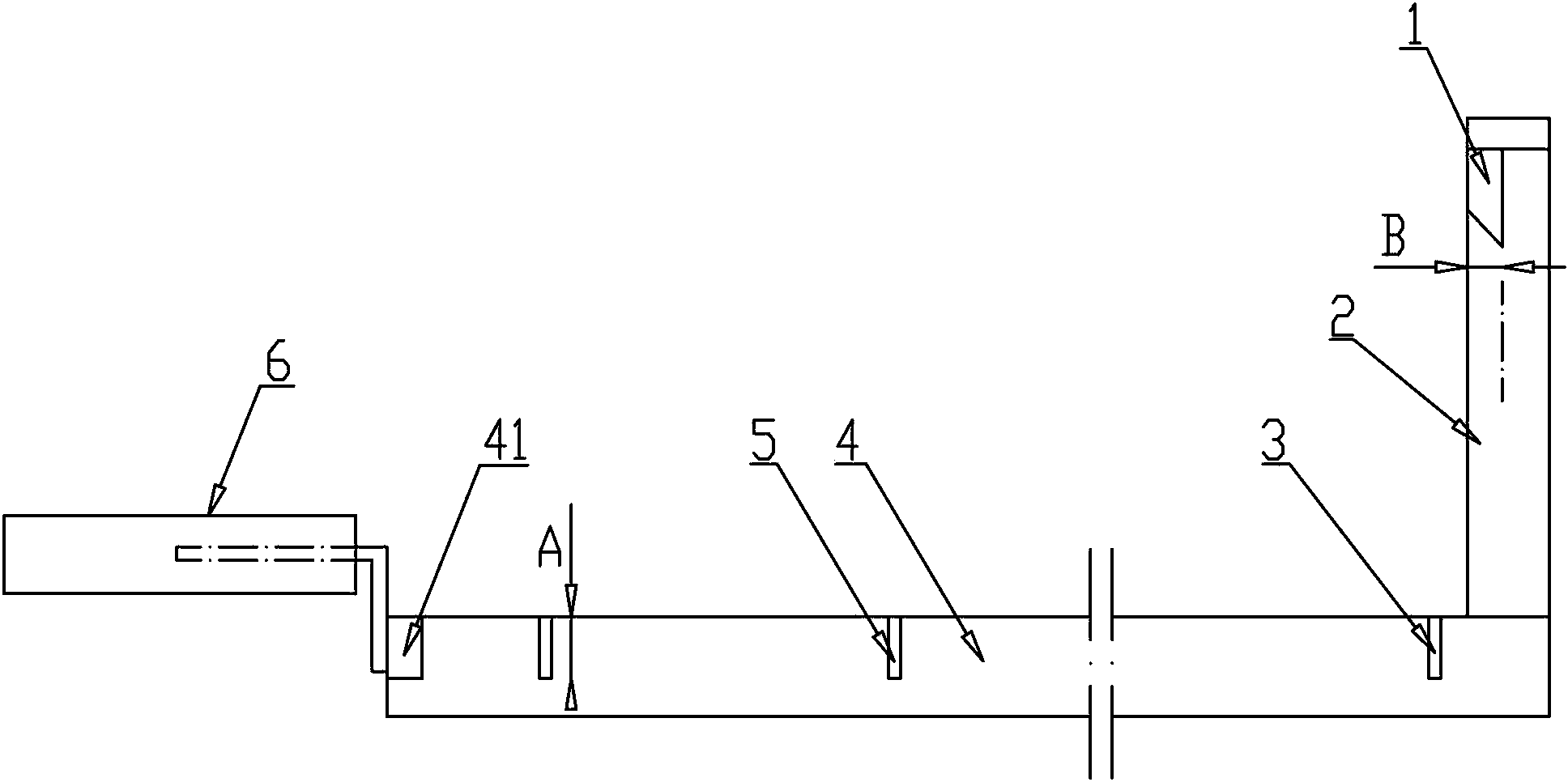

[0039] Embodiment 1 is mainly used for the lining of horizontal mortar joints, and as figure 1 As shown in , not only horizontal mortar joints are commonly used in reality, but also vertical mortar joints on facades. Therefore need to develop the mold that can line horizontal mortar joint and vertical mortar joint simultaneously.

[0040] Such as Figure 1~4 Among them, a mortar joint lining mold for aerated concrete block walls includes a bottom frame 4, one end of the bottom frame 4 is provided with an end plate 41, two sides are provided with side plates 42, the other end of the bottom frame 4 is connected to the vertical Face frame 2 connection;

[0041] End plate 41 is flush with the upper end face of side plate 42, and the length of end plate 41 is greater than or equal to the width of the upper end face of brick 7, and the height of side plate 42 is greater than the height of end plate 41, so that the lower end inner wall of side plate 42 is clamped. on the upper sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com