Masonry mortar for autoclaved aerated concrete

A technology of masonry mortar and autoclaved gas filling, which is applied in the field of building materials, can solve problems such as difficulties in construction and sizing, and achieve the effects of solving sizing difficulties, improving mechanical construction performance, and evenly smearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

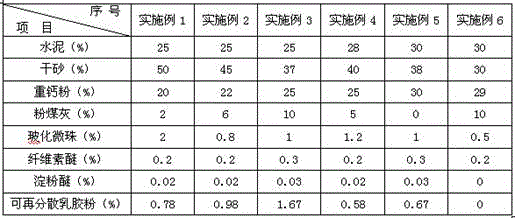

[0026] As shown in Table 1, weigh and mix the raw materials according to the mass percentage, add 22-25% of water and stir to form a uniform non-agglomerated thick mixture.

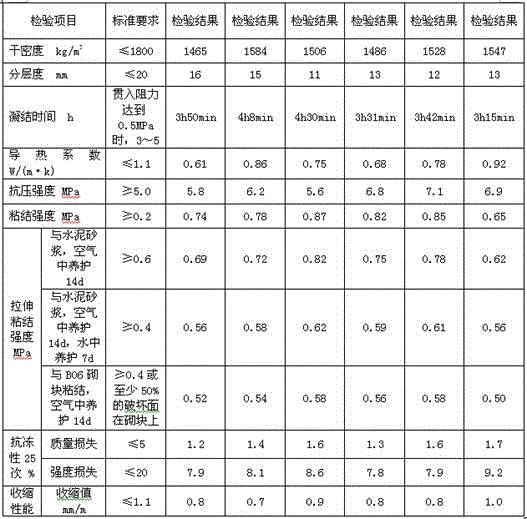

[0027] Table 1

[0028]

Embodiment 1

[0029] In Example 1, a relatively large amount of dry sand and thermal insulation filler are used, and its thermal conductivity is the lowest under the guarantee of compressive strength and bond strength; in actual mechanical construction, compared with other examples, its pumping performance is slightly worse.

Embodiment 2

[0030] Embodiment 2 On the basis of Embodiment 1, the consumption of fly ash and redispersible latex powder is gradually increased, and the consumption of vitrified microspheres is reduced. The compressive strength and tensile bond strength increase, but the thermal conductivity also increases. significantly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com