Masonry mortar production process

A technology for masonry mortar and production technology, applied in the field of masonry mortar production technology, can solve the problems of construction sizing difficulty, hollow bulge, etc., and achieve the effects of solving sizing difficulty, uniform application and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

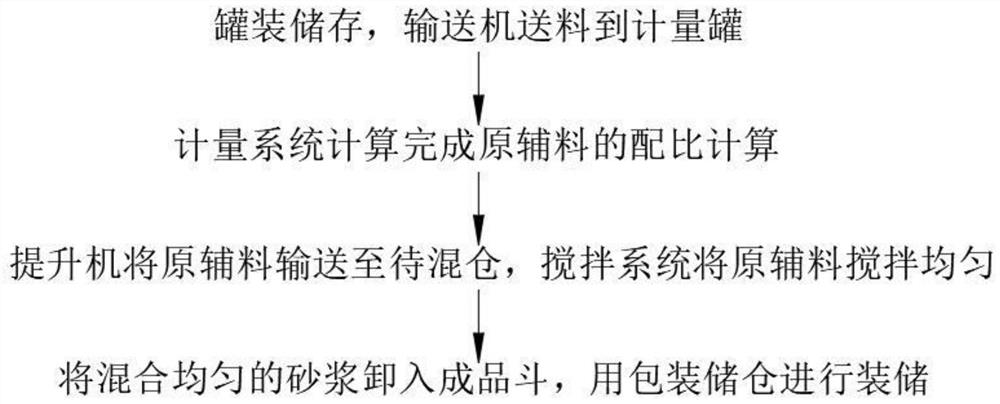

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0016] Such as figure 1 As shown, a kind of masonry mortar, including raw and auxiliary materials are dried fine sand, cement, talcum powder, hydroxypropyl methylcellulose, dispersible latex powder, hydroxypropyl starch and bonding agent, dried fine sand The river sand is 70~120 mesh and the quality is 480KG~500KG. The cement is Portland cement 42R5 and the quality is 270KG~300KG. The talcum powder is heavy calcium carbonate and the quality is 190KG~200KG. Ten thousand viscosity and mass 2.2KG~2.5KG, dispersible latex powder 3.8KG~4KG, hydroxypropyl starch 0.4KG~0.5KG, bonding aid 1.9KG~2KG. The mortar has high water retention and good construction workability, which can effectively meet the requirements of mortar thin layer construction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com