Hollow glazed-face acid-resistant brick

An acid-resistant brick and cavity technology, applied in vertical pipes, building components, building insulation materials, etc., can solve the problems of low water absorption, impermeability, large water absorption, and large volume, and achieve low water absorption and high density. The effect of high degree and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

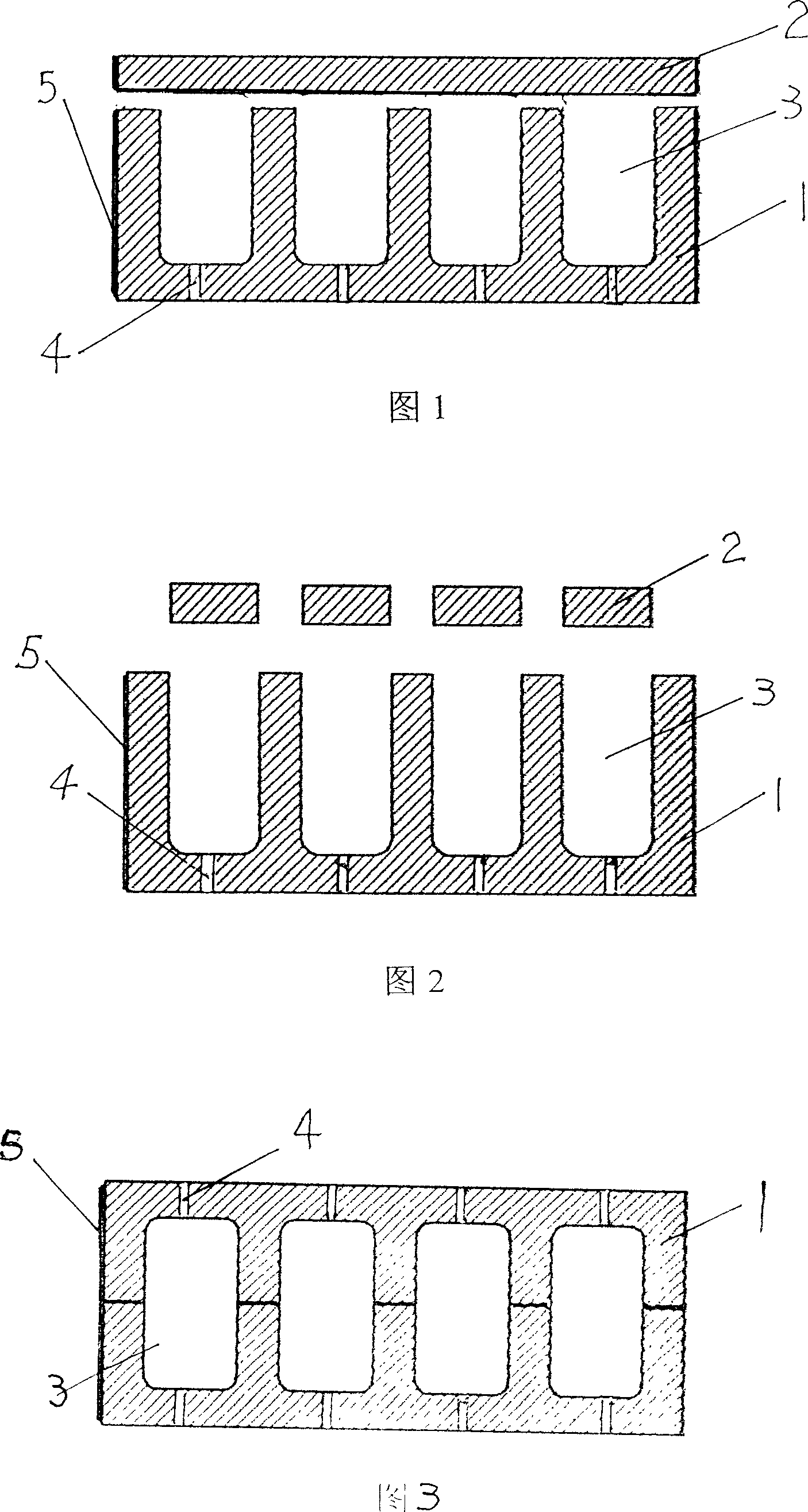

[0013] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings through the preferred embodiments.

[0014] See attached drawings 1-3 for details, a cavity glazed acid-resistant brick, including a brick body 1 with a glazed surface 5, and more than one cavity 3 is arranged inside the brick body, and the number of cavities can be set according to different specifications Multiple cavities3. The shape of the horizontal cross-section of the cavity of the brick body is various shapes such as quadrangle, circle or ellipse, and can be applied to brick bodies of various shapes and specifications used in various chimneys or flue linings. The cavity is provided with an air vent 4, which can prevent the cavity from bursting during the firing process of the adobe. The cavity is the hollow inside the brick body and the cover 2 is added or the cover is respectively arranged in the hollow opening of the brick body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com