Prefabricated filling wall system with hollow thermal insulation structure and construction method thereof

A technology for filling walls and hollows, applied to building structures, walls, building components, etc., can solve the problems of poor seismic performance, low construction efficiency, poor thermal insulation performance, etc., achieve low construction strength, improve construction efficiency, and good thermal insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

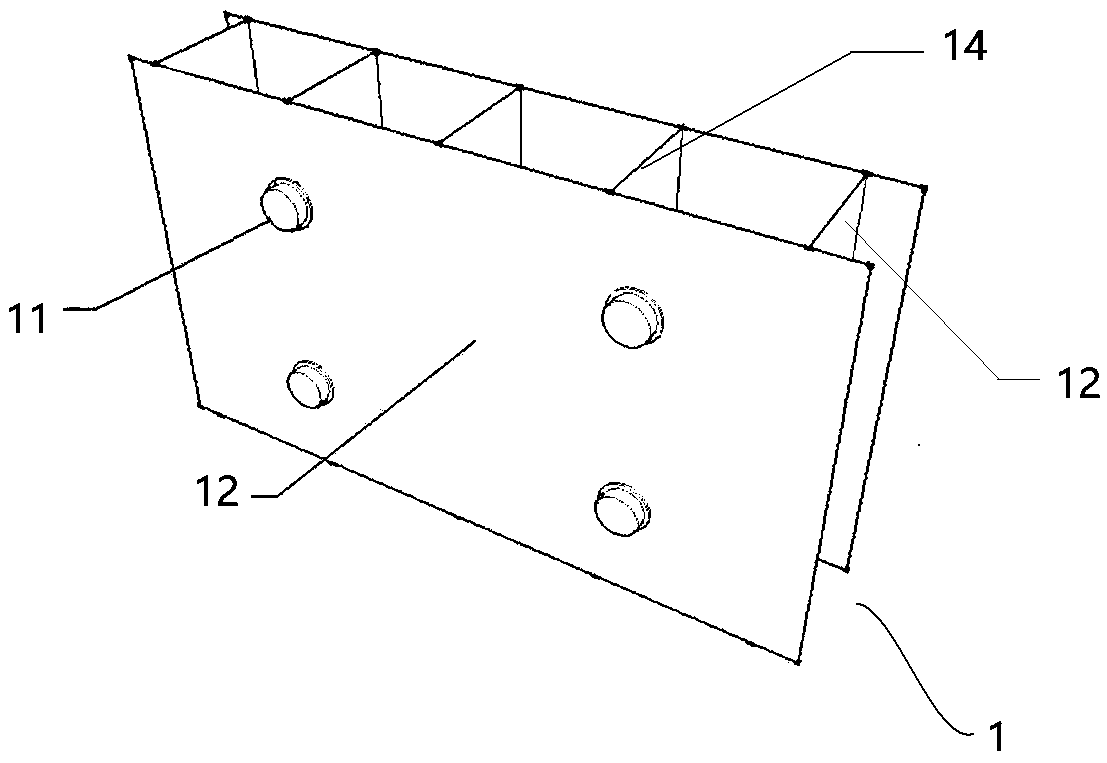

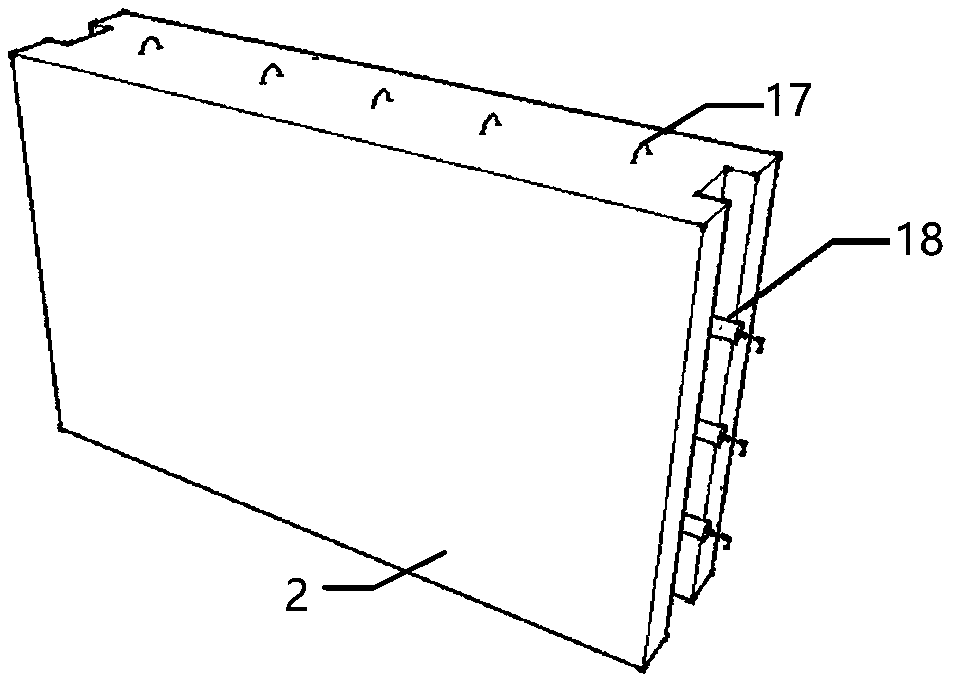

[0052] like figure 1 As shown, the present invention provides a prefabricated filling wall with a hollow thermal insulation structure with simple structure, reasonable setting, good thermal insulation and sound insulation performance. The prefabricated filling wall 16 includes the cavity box structure 1 and the cavity box structure 1 1 Concrete shell 2 on the outside.

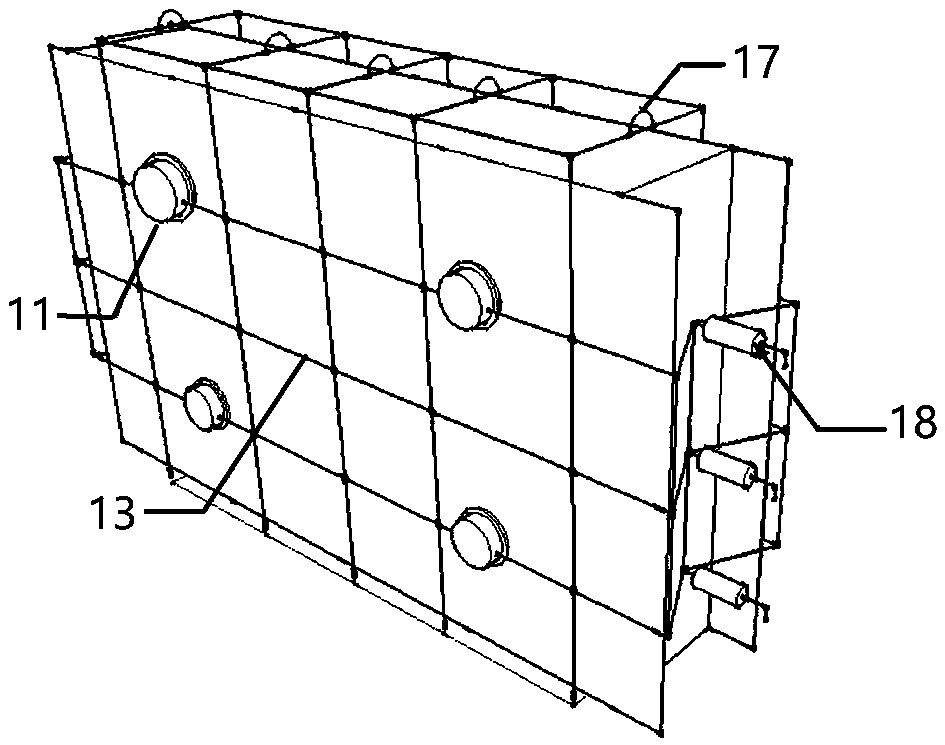

[0053] The hollow box structure 1 includes a spacer 11, a steel grid frame 13, a hollow box body surrounded by box wall panels 12, and partitions 14 arranged in parallel intervals in the hollow box body, the hollow box body Filled with desiccant and dry air. The box wallboard 12 and the cushion block 11 can be made of plastic material, which has the advantages of energy saving, greenness and environmental protection.

[0054] like figure 2 As shown, at least four pads 11 are symmetrically arranged on the front and rear box wall panels 12 of the hollow box body; Specifically, there are at least three horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com