Hollow glazed acid-proof brick and preparation method thereof

A technology for acid-resistant bricks and cavities, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve problems such as low yield and complicated process, achieve low water absorption, improve anti-seepage performance, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

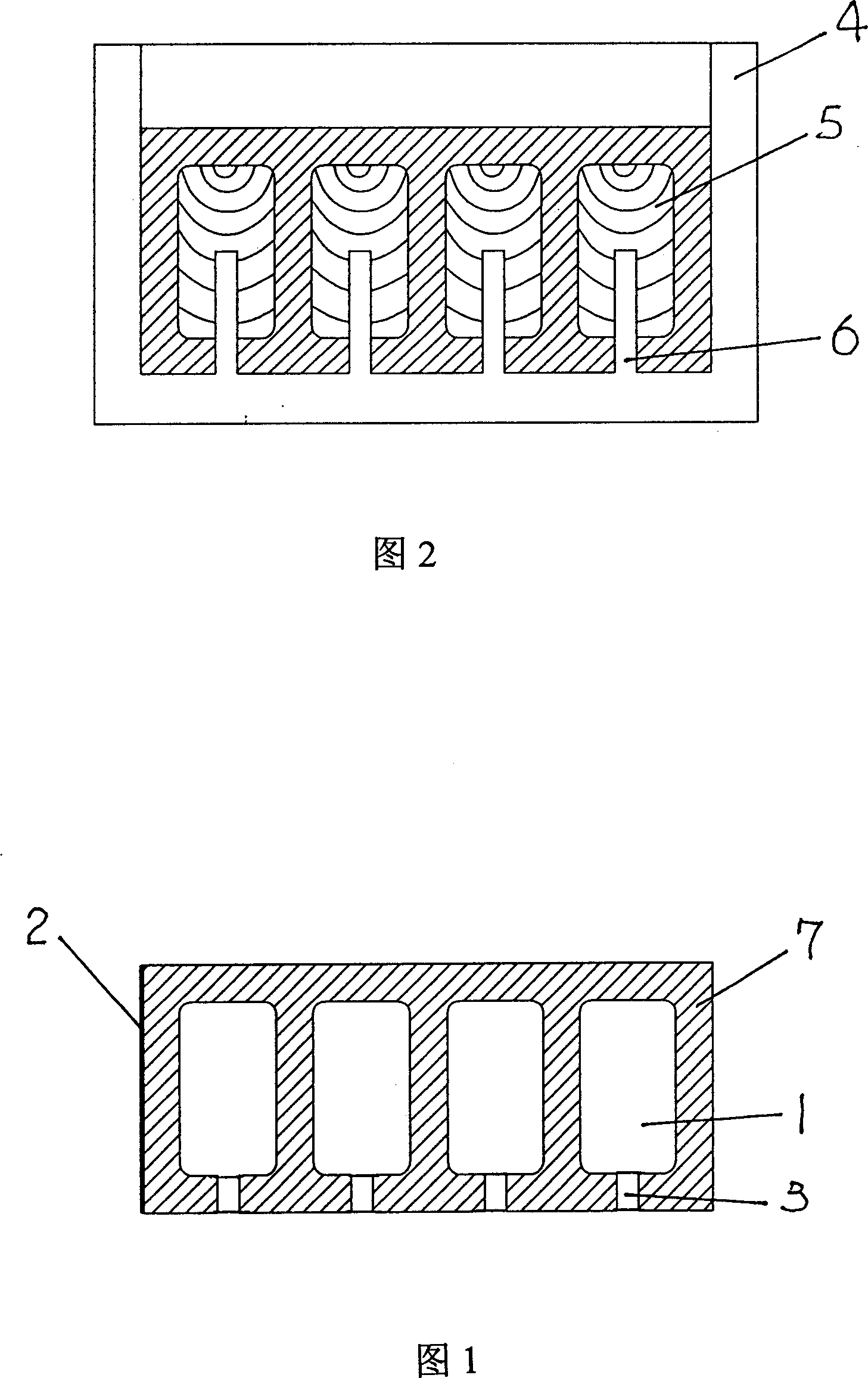

[0016] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings through the preferred embodiments.

[0017] See attached drawings 1-2 for details, a cavity glazed acid-resistant brick and its preparation method, comprising a brick body 7 with a glazed surface 2 on the outer surface and more than one cavity inside, the feature is: the inside of the brick body The cavity is a one-time molded cavity 1, and the cavity is provided with an exhaust hole 3.

[0018] The preparation method of the cavity glazed acid-resistant brick is:

[0019] 1. Mud making: choose acid-resistant clay, acid-resistant china clay or their mixture, and use ceramic technology to make mud;

[0020] 2. One-time forming blank: put the mud into the mold and use a press to press the one-time forming cavity brick.

[0021] (1) Outer mold 4: the inner wall of the outer mold has the same shape as the adobe to be formed, and a column pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com