Masonry construction method of crown bricks among wall body beam, floor slab bottom and infilled wall

A construction method and infill wall technology, which can be used in construction, building components, manufacturing tools, etc., can solve problems such as hidden dangers of engineering quality, time-consuming and labor-intensive, and large workload, and achieve reduced engineering costs, simple mold structure, and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

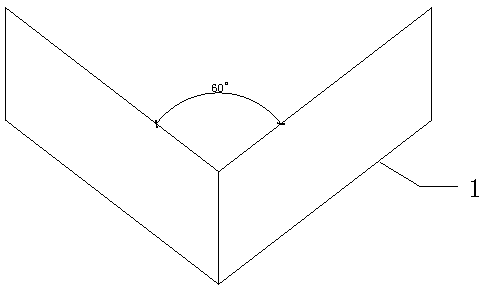

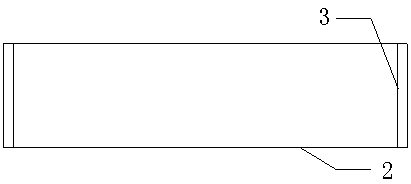

[0033] The masonry construction process of the top brick between the wall beam, the bottom of the floor slab and the filling wall of the present invention: familiarize yourself with the drawings → make the prefabricated block mold fastening clamp plate → locate the triangular mold slot → make the triangular mold → fix and fasten the steel bar → triangular The mold is fastened with the fastening clamp → the concrete is poured in the mold and compacted and finished → the mold is removed → the triangular concrete prefabricated block is cured → the triangular concrete precast block is used for construction.

[0034] The masonry construction method of the top brick between the wall beam, the floor bottom and the filling wall of the present invention is applicable to the oblique laying of the top brick of the wall body of a residential building, comprising the following steps:

[0035] a. Make the triangular concrete prefabricated block mold between the wall beam, the bottom of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com