Deep Maintenance Method of Coke Oven Carbon Bottom Brick

A technology for in-depth maintenance and bottom bricks, which is applied in coke oven bricklaying operations, preventing/repairing bricklaying leakage, etc. It can solve problems such as damage to the entire row of carbon bottom bricks, achieve fast masonry speed, and avoid large fluctuations in furnace temperature , The effect of shortening the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

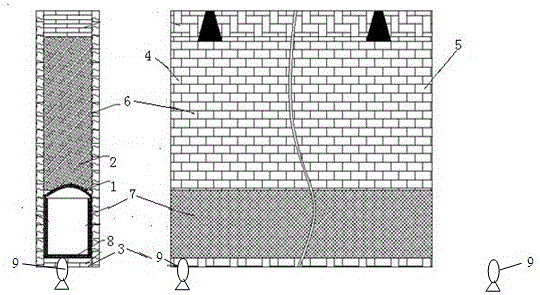

[0018] The in-depth maintenance method of coke oven carbon bottom bricks is to choose a zero-expansion silica brick with an expansion rate of about 0.2% to replace the furnace bottom silica brick at the damaged part of the carbonization chamber, which can avoid cracks in the silica brick at a high temperature of 850 ° C, and zero Expanded silica bricks do not require preheating before use, and have good wear resistance. The method includes the following steps: 1) Furnace temperature control, according to the temperature control technical plan before construction, the furnace temperature is lowered and controlled within the range of 850°C-950°C; 2) 850°C heat insulation, on-site production and completion of the carbonization chamber 3) Interval roof protection, manufacture and install roof protection facilities on site; 4) Safety protection technology for construction personnel in limited space, install ventilation and heat insulation facilities on site, and do a good job in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com