Thin wallboard and composite wall thereof

A wallboard and wall technology, applied in the field of combined walls assembled with thin wallboards, can solve the problems of slow masonry speed, long cycle, cracking and leakage, etc., achieve faster masonry speed, shorten the masonry cycle, overcome The effect of cracking and leaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

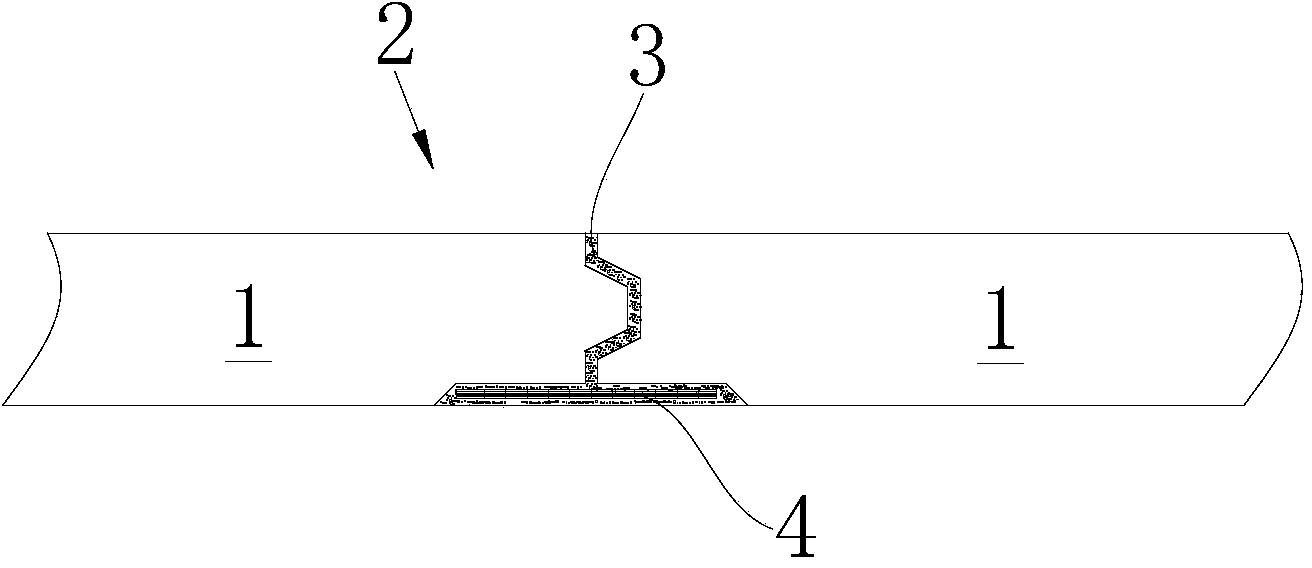

[0026] The specific implementation of the thin wallboard and its combined wall body of the present invention will now be described in conjunction with the accompanying drawings.

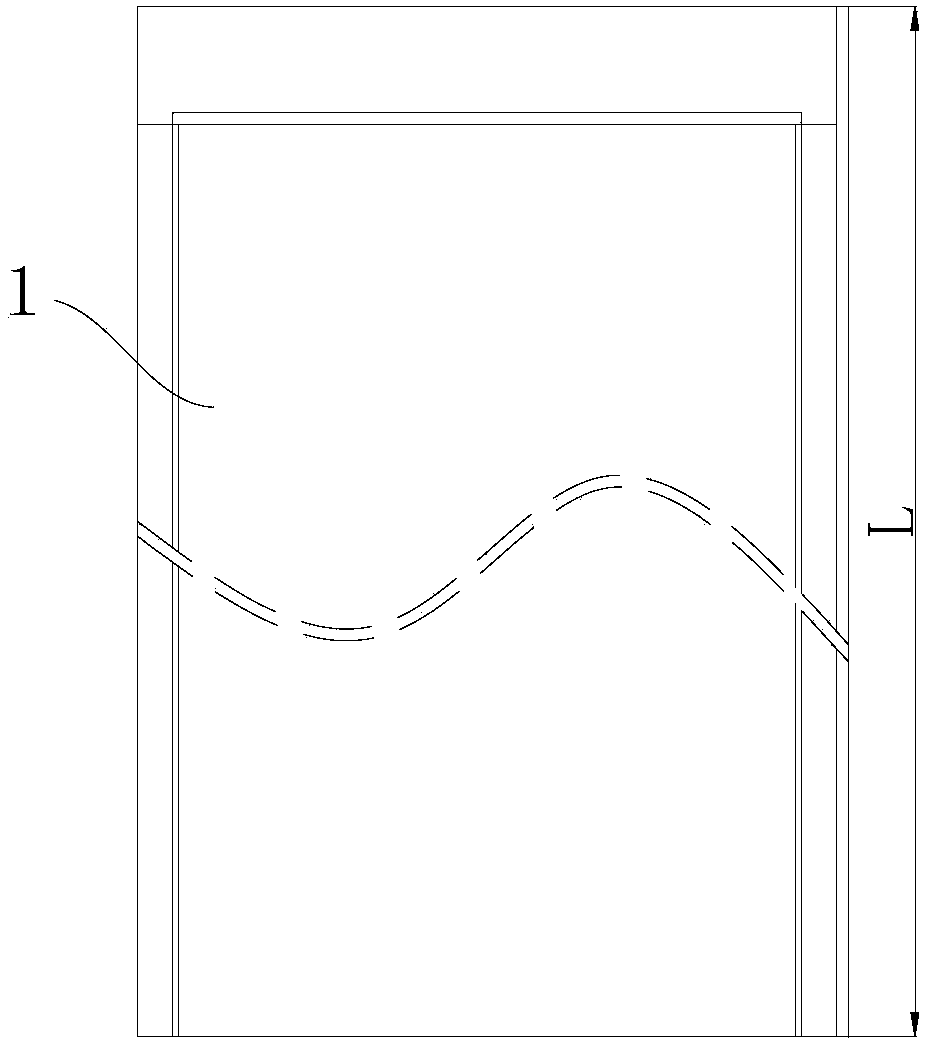

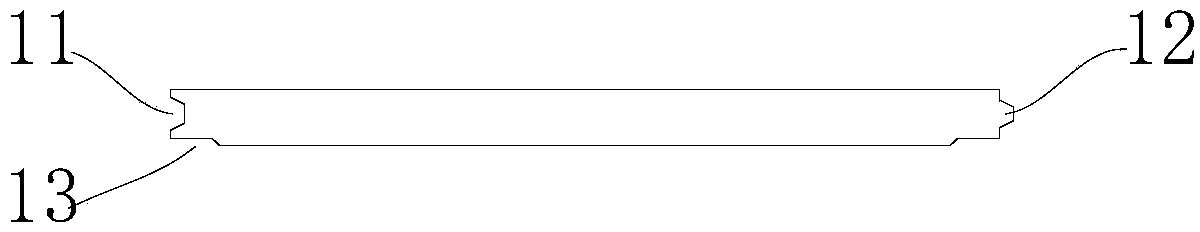

[0027] see figure 1 with figure 2 As shown, the thin wallboard of the present invention comprises an integral wallboard 1 poured and formed with ceramsite concrete, wherein the length L of the wallboard is 30-50 mm smaller than the distance from the ground to the bottom surface of the top structural beam or the bottom surface of the floor slab; One of the two sides in the length direction of the wallboard is provided with a through mortise 11 , and the other side is provided with a mortise 12 matching with the mortise 11 .

[0028] The thin wall panel of the present invention is an integral wall panel formed by pouring ceramsite concrete, and the length of the wall panel is 30-50 mm shorter than the distance from the ground to the bottom surface of the top structural beam or the bottom surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com